3

Product Identification

DAR

Nominal Cooling Capacity

Model Series

DAR

0904 - 90,000 Btuh (7 1/2 Tons)

1204 - 120,000 Btuh (10 Tons)

Product Description

When matched with DX11 and DZ11 condensers, this system com-

plies with the minimum efficiency requirements found in ASHRAE

90.1-2007. See the Daikin DX11 and DZ11 specification sheets for

details on these condensers. For other Daikin condenser(s) that

can be matched with this airhandler to obtain ASHRAE 90.1-2007

compliance, consult with your local distributor.

The DAR series is intended for use with a room thermostat. This

thermostat is not supplied with this equipment. Only thermostats

that use 24 VAC control circuitry are to be used.

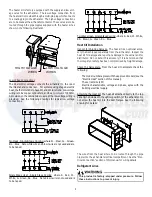

DAR0904

DAR1204

Net Weight (Lbs.)

375

400

Shipping Weight (Lbs.)

405

430

Refrigerant

R-410A

R-410A

Blower Wheel (Dia x Width)

11X10

11X10

Blower Wheel Quantity

2

2

Motor Type

Belt Drive

Belt Drive

Motor Qty

1

1

Motor (HP)

1 1/2

2

Motor (RPM)

1750

1750

Motor Sheave Type

Motor Sheave Diameter (in)

1.9" - 2.9"

2.8" - 3.8"

Blower Wheel Pulley Type

Blower Wheel Pulley Dia (in)

5.9

5.9

Evaporator Coil Material

Face Area (Ft

2

)

8.9

10.0

Number of Rows

4

4

Suction Line Quantity

1

2

Suction Line Connection (in) *

1 1/8

1 1/8

Liquid Line Quantity

1

2

Liquid Line Connection (in)*

5/8

3/8

Metering Device

TXV Type

TXV Quantity

1

2

*Note: Consult with the condenser specific ations for suc tion and liquid

line sizing.

Adjustable Variable Pitch

Fixed Diameter

Copper Tubes / Al Fins

Thermal Expansion Valve (TXV)

Non-adjustable (factory installed)

Unit Inspection

Upon delivery, the unit is to be inspected for damage. Any dam-

age must be reported immediately to the carrier. Do not install

this equipment if it is determined that the integrity or safety has

been compromised by freight damage.

Using the table “Model Identification” section check the equip-

ment model number to ensure the unit is appropriately sized for

the condenser unit(s).

If an incorrect unit is supplied it must not be installed and it is to

be returned to the supplier. The manufacturer assumes no re-

sponsibility for the installation of incorrect delivered units.

The evaporator coil contains a high-pressure inert gas holding

charge.

Codes & Regulations

This product is designed and manufactured to comply with na-

tional codes. Installation in accordance with such codes and/or

prevailing local codes/regulations is the responsibility of the in-

staller. The manufacturer assumes no responsibility for equip-

ment installed in violation of any codes or regulations.

The United States Environmental Protection Agency (EPA) has

issued various regulations regarding the introduction and dis-

posal of refrigerants. Failure to follow these regulations may

harm the environment and can lead to the imposition of sub-

stantial fines. Should you have any questions please contact the

local office of the EPA.

Replacement Parts

When reporting shortages or damages, or ordering repair parts,

give the complete product model and serial numbers as stamped

on the product. Replacement parts for this product are available

through your contractor or local distributor. For the location of

your nearest distributor consult the white business pages, the

yellow page section of the local telephone book or contact:

CONSUMER AFFAIRS

DAIKIN NORTH AMERICA LLC

7401 SECURITY WAY

HOUSTON, TEXAS 77040

855-770-5678

If replacing an air handler, the system must be manufacturer ap-

proved and Air-Conditioning, Heating, and Refrigeration Institute

(AHRI) matched. NOTE: Installation of unmatched systems is

strongly discouraged.

Pre-Installation Instructions

Carefully read all instructions for the installation prior to install-

ing product. Make sure each step or procedure is understood and

any special considerations are taken into account before starting

installation. Assemble all tools, hardware and supplies needed

to complete the installation. Some items may need to be pur-

chased locally. Make sure everything needed to install the prod-

uct is on hand before starting.