10

Evaporator Coil TXV

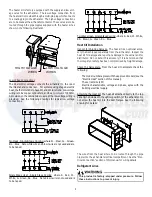

Note: Thermal Expansion Valve (TXV) Bulb is not permanently con-

nected to the suction from the factory. After suction and liquid

line tubing is brazed in the field, the TXV bulb must be attached

and insulation to the suction line(s) inside the cabinet at the 10 or

2 o’clock position. This location will be different depending on

the orientation of the unit, vertical or horizontal. Always locate

the TXV bulb on the top of the suction tube at 10 or 2 o’clock.

Check condensing unit / heat pump instructions for charging

method.

Airflow

The blower uses a belt drive motor that has an adjustable

sheave. The factory setting for the DAR0904 is 2 turns open

and the DAR1204 is 3 turns open.

To increase the airflow:

•

Remove the blower belt

•

Loosen the set screw as shown below

•

With the sheave stationary - rotate the other half clockwise

(screw in).

•

Tighten the set screw

•

Reinstall the belt

To decrease the airflow perform the same as above but rotate

the sheave counterclockwise (screw out).

The following table can be used as guide for system airflow:

Static

Pressure

1

2

3

4

5

0.1

4264

3930

3633

3273

0.2

3996

3705

3325

2998

0.3

3731

3379

3002

2517

0.4

3445

3066

2613

-

0.5

3113

2662

-

-

DAR0904

Sheave Turns Open

Static

Pressure

0

1

2

3

4

5

0.1

5193

5037

4790

4529

4097

4097

0.2

5012

4873

4603

4315

3842

3842

0.3

4852

4675

4393

4091

3589

3589

0.4

4687

4484

4172

3853

3295

3073

0.5

4501

4268

3939

3561

2922

2610

0.6

4293

4041

3673

3223

2642

-

0.7

4073

3782

3347

2892

-

-

0.8

3807

3485

2962

-

-

-

0.9

3540

3117

-

-

-

-

DAR1204

Sheave Turns Open

Belt Tension

The belt tension is to be checked at the time of installation and

after a “run in” period of about 24 hours. To perform the

measurement, it is suggested that a “Belt Tension Gauge”

(available from most belt manufacturers) be used. The force

required to deflect the belt 1/8" (at the midpoint) should be

between 3 ½ and 5 pounds.