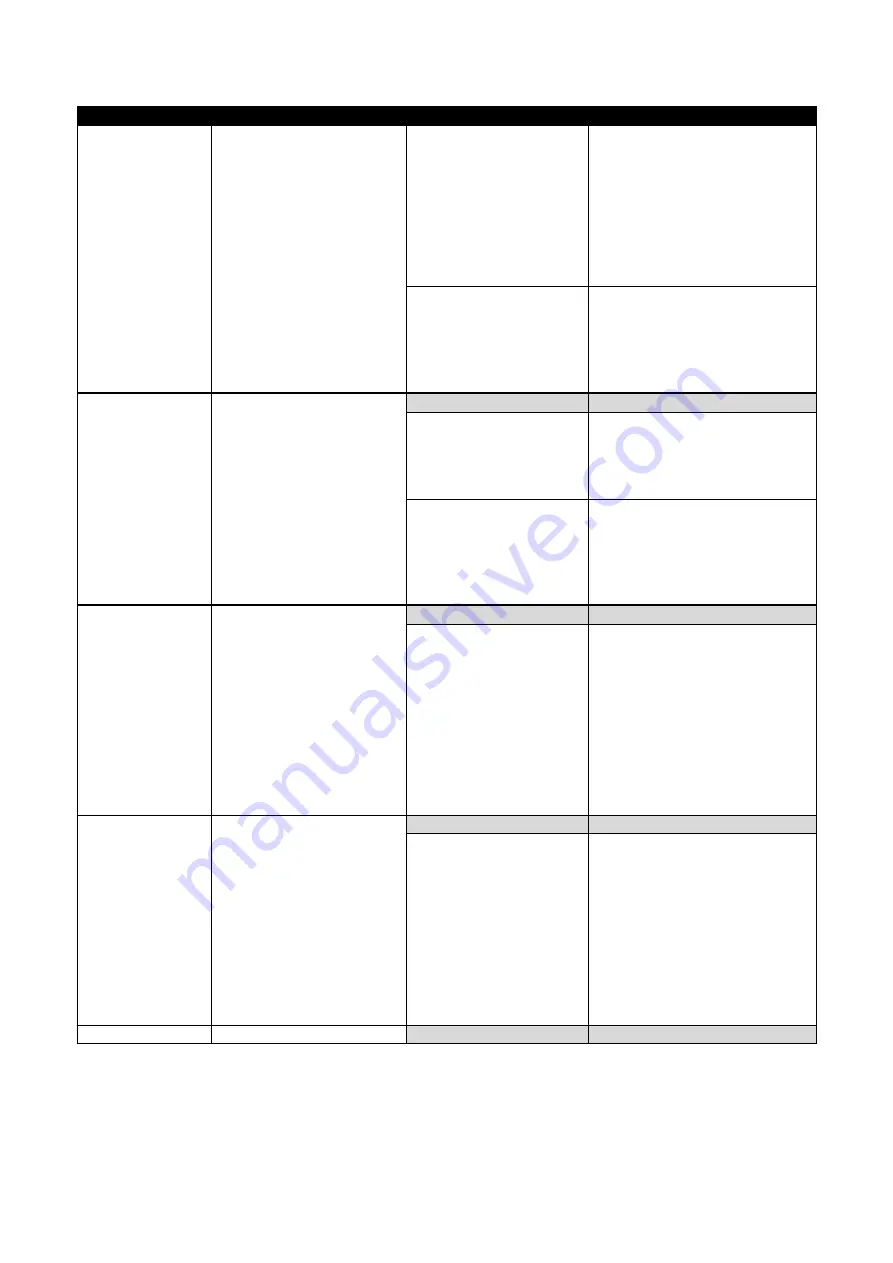

D-EOMOAH00903-21_01EN - 24 / 37

Alarm String

Description

Possible causes & solutions

Heating Pump:

Alarm

Heating pump possible

malfunction.

This alarm occurs when the

water pump communicate to

the controller an alarm

condition.

The alarm signal of the

water pump is not

connected to the controller

Check the wiring connection

between the input “Cooling/Heating

coil pump alarm” (water coils

combined) or “Heating coil pump

alarm” (water coils separated or

only a heating water coil present)

of the controller and alarm output

of the pump

The pump is in a fault state

- Refer to troubleshooting of the

water pump

- Check the electrical connection of

the pump

- Replace the pump if broken

Cooling Pump:

Alarm

Cooling pump possible

malfunction.

This alarm occurs when the

water pump communicate to

the controller an alarm

condition.

Causes

Solutions

The alarm signal of the

water pump is not

connected to the controller

Check the wiring connection

between the

input “Cooling/Heating

coil pump alarm” of the controller

and alarm output of the pump

The pump is in a fault state

- Refer to troubleshooting of the

water pump

- Check the electrical connection of

the pump

- Replace the pump if broken

Supply #

filter Warning

# = 1,2,3,4

Supply # filter warning.

Filter is dirty, the warning is

notified in the HMI, but unit

can still run.

It occurs when the measured

differential pressure is

greater than the warning

threshold set in Setpoints

submenu.

Causes

Solutions

The filter is dirty

Plan to change the filter

Return #

filter Warning

# = 1,2

Return # filter warning.

Filter is dirty, the warning is

notified in the HMI, but unit

can still run.

It occurs when the measured

differential pressure is

greater than the warning

threshold set in Setpoints

submenu.

Causes

Solutions

The filter is dirty

Plan to change the filter

Causes

Solutions