5.5.4. Injection pump

•

Check the fuel injection pump housing for cracks or breaks, and replace if damaged.

•

Check and see if the lead seal for idling control and speed control levers have not been

removed.

•

No alterations must be made to the injection pump. If the lead seal is damaged the warranty

on the engine will become null and void.

•

We strongly recommended that any faults developing in the injection pump should be taken

care of by authorized specialist personnel.

5.6. Injection Nozzle Maintenance

( by authorized specialist personnel )

- The injectors are designed to spray the

fuel delivered by the injection pump

directly into the spherical combustion

chamber in the piston crown.

- The injector consists of the nozzle and

the nozzle holder.

- A copper seal fitted to the injector

ensures gas-tight seating and good heat

dissipation.

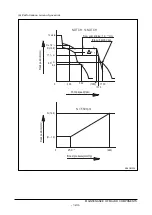

- The opening pressure of the nozzle is

adjusted by means of shims at the com-

pression spring.

•

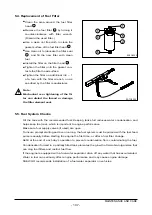

Install a nozzle to a nozzle tester.

•

Check injection pressure, and adjust the nozzle using the adjusting shim if the pressure does

not meet the specified limit.

•

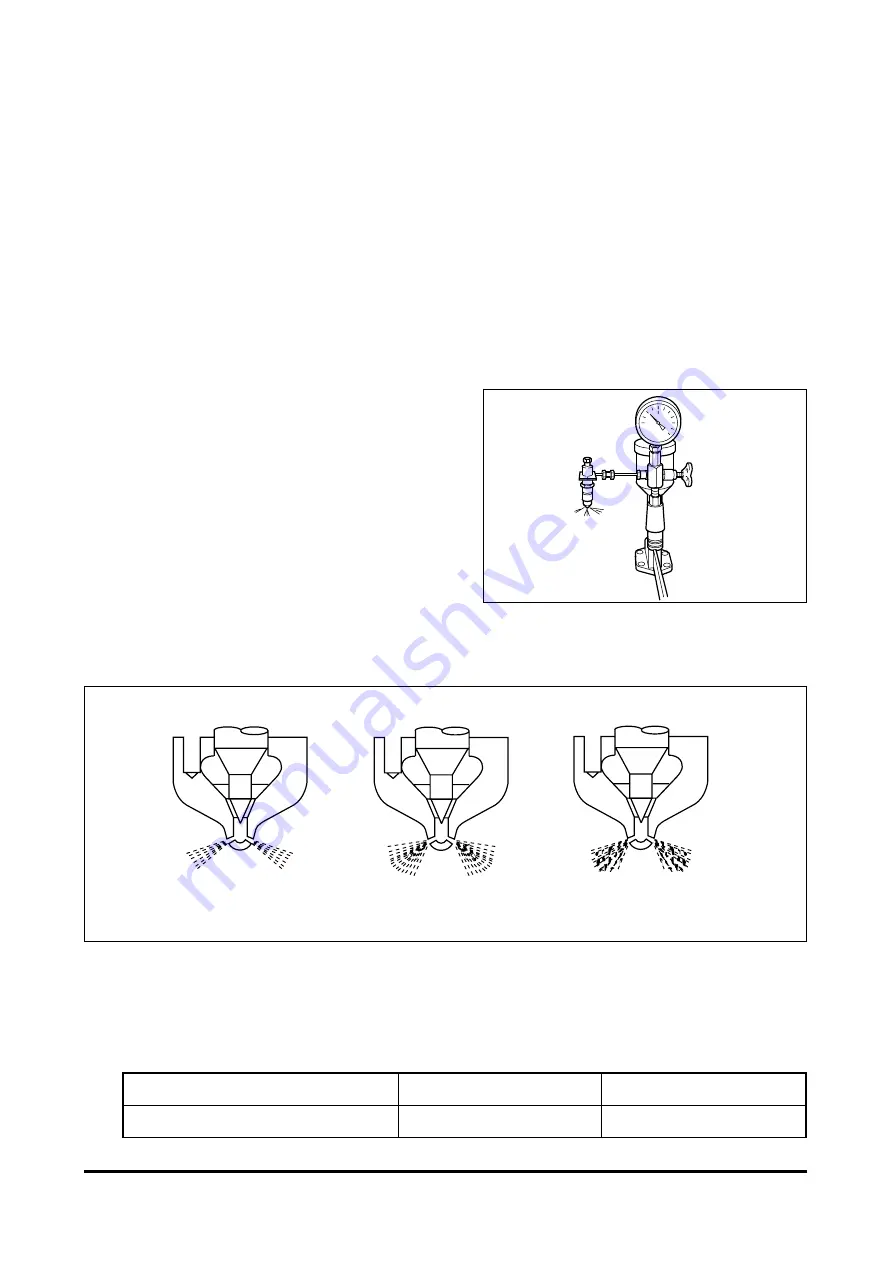

Check nozzle spray patterns and replace if damaged.

- 109 -

MAINTENANCE AND CARE

EA0M3003

EFM1006I

Normal

Abnormal

Abnormal

Engine Model

DE12T/TI/TIA

DE12TIS

Injection nozzle pressure

220 kg/cm

2

160 / 220 kg/cm

2

Содержание DE12T

Страница 2: ......

Страница 64: ...3 1 42 Oil spray nozzle Unscrew the fixing bolt and remove the oil spray nozzles 60 DISASSEMBLY ...

Страница 102: ...3 3 43 Oil level gauge Assemble the oil level gauge and guide tube on the oil pan 98 REASSEMBLY EQM3005I ...

Страница 187: ... Engine Assembly DE12TIS ECIEA 183 APPENDIX EE6OM026 ...

Страница 188: ......