70

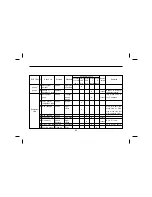

Check points (operation)

Items Procedure & check point

Before operation

During operation

Stop

1. Check for V–belt tension and damage.

2. Check for fixing position of crank pulley, tension pully and clutch pully.

3. Check for clogged inlet of cooling–air and filter mat.

4. Keep compressor clean without dust or oil. If not, clean it with compressed air.

5. Check for fixing condition of bolts and nuts. If not, retighten them.

6. Check for gas–leak of connected position with leak–tester and retighten.

1. Check for operation when turning on the main switch after starting engine.

2. Check for operation of vent, cooling and unloading by using the temperature volume.

3. Check for capacity of cooling air from ducts.

4. Check for operation of high–low pressure switch.

Low pressure set : 0.5kg/cm

2

(warning light turn “on” and compressor clutch is disconnected)

High pressure set : 0.5kg/cm

2

(warning light and buzzer turn “on” and compressor clutch is disconnected)

1. Check for stopping of cooler when pushing button switch to turn off.

2. Check for stopping when turning off the main switch.

Содержание BH090

Страница 122: ...120 EARPHONE OPTION 1 Volume controllor 2 Select the media Tape 1 Tape 2 Radio TV VTR 3 Earphone jack 3 2 1...

Страница 214: ...212 1 Cover RR fuse box 2 Bracket Rr fuse box 3 Regulator Assembly 4 18P Fuse box Rear fuse box 1 3 4 2...

Страница 220: ...218 Drag link RR 2 points For leaf spring Spring and shackle pin 12 points...

Страница 255: ...253 BODY DIMENSION BM090 ROOF ON COOLER NON COOLER APPROX APPROX...

Страница 256: ...254 BS090...

Страница 257: ...255 1853 1853 3225 3225 2490 2490 2050 2050 35 35 1975 1975 4200 4200 8990 8990 2750 2750 30 30 BH090...

Страница 258: ...256 ROOF ON COOLER SUB ENG COOLER NON COOLER 2050 2100 70 70 3110 5200 10550 1853 2490 3225 APPROX 3110 APPROX BS106...

Страница 259: ...257 ROOF ON COOLER SUB ENG COOLER NON COOLER APPROX APPROX BH115E...

Страница 260: ...258 ROOF ON COOLER SUB ENG COOLER APPROX APPROX BH120E...