Page 1-3

s

eCTion

1 - P

roduCT

f

amiliarizaTion

Long Term Storage With a Higher Level of Performance

One of the most discouraging aspects of long term frozen food

storage is freezer burn. Freezer burn is most often the result of the

outer layers of the product thawing slightly and refreezing multiple

times. One of the most common causes of this thawing is the

defrost cycle needed for modern frost-free products.

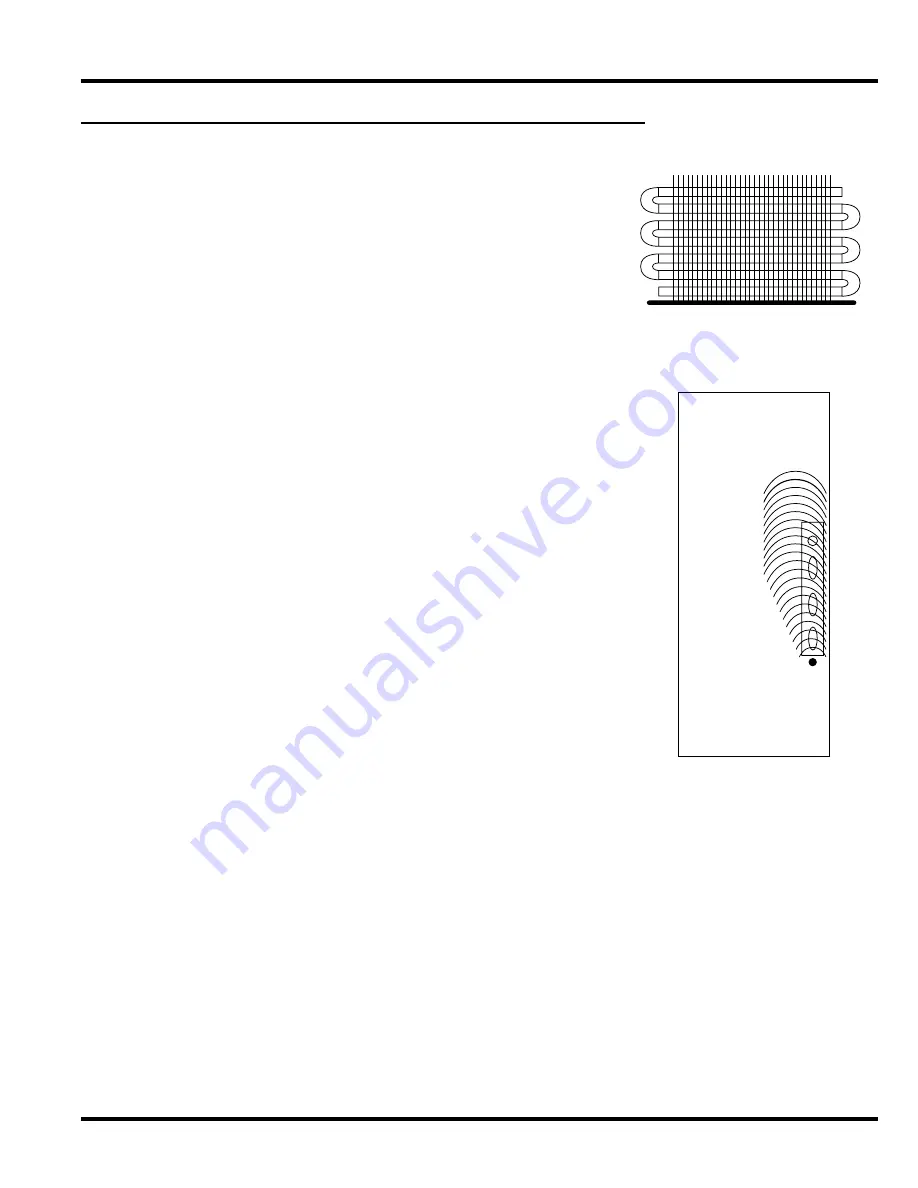

When the system enters a defrost cycle, a heater is turned on to

warm the cooling coil in the freezer and melt any frost off from the

coil before it has the opportunity to affect the performance of the

system. While the coil is heating, it is not uncommon for the area

around the coil to heat enough to thaw the outer layer of product

and in-turn create freezer burn.

The Dacor Built-in Refrigerators minimize temperature swings

during defrost with two different features. One of the features is

Preemptive Adaptive Defrosting while the other is sub-cooling prior to

defrost.

Many manufacturers have added adaptive defrost to their product

lines. Adaptive defrost adapts to the use and environment of the

product and provides defrost cycles only when necessary. Not only

does this often result in fewer defrost cycles that could potentially

damage the freezer contents, it allows for energy saving.

Preemptive adaptive defrost takes this energy and food saving even

further by attempting to make sure that the defrost happens when

the refrigerator and freezer are not being used. In a normal adaptive

defrost, when it is time for a defrost, the defrost starts. This may

mean that a defrost cycle could start in the middle of preparing

dinner. At a time when refrigerator usage is at maximum, the system

is defrosting and cannot provide the cooling needed to maintain

optimum temperatures.

With a preemptive adaptive defrost, the system looks forward and

anticipates usage patterns to avoid defrosting at a time that may not

be best. The control tracks information about how the owners use

the refrigerator. The refrigerator has learned that between four and

seven in the afternoon there are a large number of door openings. A

large number of door openings translates to a high use period. If the

system identifies that a defrost is scheduled to happen around five-

thirty, it must make a decision. Either perform the defrost at 3 PM,

before the high use period, or wait until 8 PM after the high use period. The decision is made by the

controller and will be based on the time elapsed since the last defrost, the measured temperatures and

the usage since the last defrost. The end result is a defrost cycle happening when it least likely to affect

the life of the freezer contents.

Another way to prevent damaging temperature swings is to lower the temperature of the freezer

contents below normal before a defrost cycle is started. If the contents are cooler than normal before

the defrost cycle begins, there is less chance that the outer layers will thaw during the defrost cycle.

The Dacor Built-in Refrigerators look ahead and before starting defrost provides maximum cooling to

the freezer compartment. The result of the maximum cooling period is lower freezer temperature. With

a lower starting temperature, the defrost can take place and overall freezer temperature may rise only

one degree above normal. This is in comparison to other refrigeration products that may rise ten or

more degrees during defrost.

By providing defrost only when needed and sub-cooling before defrost, the Dacor Built-in Refrigerators

help protect the owner’s investment in fine groceries and allows them to make purchases at their

convenience instead of on demand.

Cooling Coil (Evaporator)

Heating Element

Freezer Compartment

Heat

Содержание EF42 Series

Страница 2: ......

Страница 12: ...Page 1 9 Section 1 Product Familiarization 48 DISPENSER MODEL ...

Страница 14: ...Page 1 11 Section 1 Product Familiarization 48 NON DISPENSER MODEL ...