Page 26

Com-Tech 200/400/800/1600 Power Amplifiers

5 Technical Information

5.1 Overview

Com-Tech amplifiers incorporate several new techno-

logical advancements including real-time computer

simulation, low-stress output stages, an advanced

heat sink embodiment and the Programmable Input

Processor (

P.I.P.) expansion system.

Custom circuitry is incorporated to limit temperature

and current to safe levels making it highly reliable and

tolerant of faults. Unlike many lesser amplifiers, it can

operate at its voltage and current limits without self-de-

structing.

Real-time computer simulation is used to create an

analogue of the junction temperature of the output

transistors (hereafter referred to as the output de-

vices). Current is limited only when the device tem-

perature becomes excessive (and by the minimum

amount required). This patented approach called Out-

put Device Emulation Protection (or

ODEP) maximizes

the available output power and protects against over-

heating—the major cause of device failure.

The amplifier is protected from all common hazards

that plague high-power amplifiers, including shorted,

open or mismatched loads; overloaded power sup-

plies, excessive temperature and chain-destruction

phenomenon; input overload, high-frequency blow-

ups, internal faults, and input and output DC.

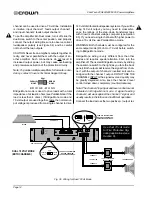

The four-quadrant topology used in a

Com-Tech

amplifier’s output stages is called the

grounded

bridge. This patented topology makes full use of the

power supply providing peak-to-peak voltages to the

load that are twice the voltage seen by the output de-

vices (see Figure 5.1).

As its name suggests, the

grounded bridge topology

is referenced to ground. Composite devices are con-

structed to function as gigantic NPN and PNP devices

to handle currents which exceed the limits of available

devices. Each output stage has two composite NPN

devices and two composite PNP devices.

The devices connected to the load are referred to as

“high-side NPN and PNP” and the devices connected

to ground are referred to as “low-side NPN and PNP.”

Positive current is delivered to the load by increasing

conductance simultaneously in the high-side NPN and

low-side PNP stage, while synchronously decreasing

conductance of the high-side PNP and low-side NPN.

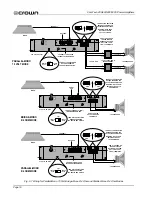

The two channels may be used together to double the

voltage (Bridge-Mono) or current (Parallel-Mono) pre-

sented to the load. This feature gives you flexibility to

maximize power available to the load.

A wide bandwidth, multiloop design is used for state-

of-the-art compensation. This produces ideal behavior

and results in ultra-low distortion values.

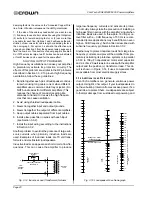

Aluminum extrusions have been widely used for heat

sinks in power amplifiers due to their low cost and rea-

sonable performance. However, measured on a watts

per pound or watts per volume basis, the extrusion

technology doesn’t perform nearly as well as the heat

sink technology developed for

Com-Tech amplifiers.

Our heat sinks are fabricated from custom convoluted

fin stock that provides an extremely high ratio of area

to volume, or area to weight. All power devices are

mounted directly to massive heat spreaders that are

electrically at the Vcc potential. Electrifying the heat

spreaders improves thermal performance by eliminat-

ing the insulating interface underneath each power de-

vice. The chassis itself is used as part of the thermal

circuit to maximize utilization of the available cooling

resources.

5.2 Circuit Theory

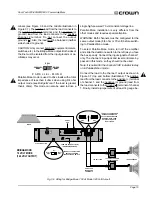

Each channel is powered by its own power transformer

winding. Both channels share a common low-voltage

supply. The secondary output of T100 is full-wave rec-

tified by D109 and is filtered by a large computer

grade capacitor. A thermal switch embedded in the

power transformer protects it from overheating.

The low-voltage winding of the transformer is rectified

by diodes D1, D2, D3 and D4 to generate an unregu-

lated 24 volts. Monolithic regulators U1 and U2 provide

a regulated ±15 volts.

5.2.1 Dual Operation

For simplicity, the discussion of Dual operation will re-

fer to one channel only. Mono operation will be dis-

cussed in Sections 5.2.2 and 5.2.3.

Please refer to the block diagram in Figure 5.1 and the

schematics provided at the back of this manual.

The signal at the

P.I.P. barrier block passes directly

into the balanced input stage (U104-A). The balanced

input stage causes balanced to single-ended conver-

sion using a difference amplifier. Next the variable gain

stage (U104-B) amplifies or attenuates the signal. The

gain of this stage is set by the position of the input sen-