7

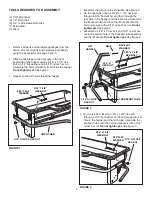

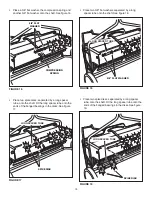

FIGURE 4

• Fasten the hitch tubes together using three 5/16" x

2-1/4" hex bolts and 5/16" nylock hex nuts.

Do not

tighten yet.

See figure 4.

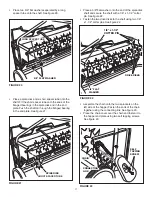

FIGURE 5

5/16" x 2-1/4"

HEX BOLT (3)

5/16" NYLOCK

HEX NUT (3)

5/16" x 2"

HEX BOLT (2)

HITCH PIN

HAIR COTTER

PIN (1/8")

5/16" NYLOCK

HEX NUT (2)

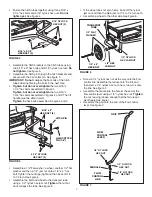

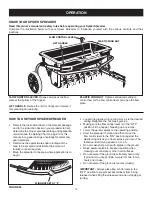

• Assemble a 1/2" flat washer, a wheel, another 1/2" flat

washer and then a 1/2" jam nut onto a 1/2" x 4" hex

bolt. Tighten the nut finger tight and then back off 1/4

to 1/2 turn. See figure 6.

• Assemble the bolt and wheel to the transport tube

using a 1/2" nylock hex jam nut.

Tighten

the nut but

don't collapse the tube. See figure 6.

FIGURE 7

FIGURE 6

1/2" HEX

JAM NUT

TRANSPORT

TUBE

1/2" x 4"

HEX BOLT

1/2" NYLOCK

HEX JAM NUT

1/2" FLAT

WASHER

• Screw a 1/4" nylock hex nut all the way onto the flow

control link. Assemble the ferrule onto the link and

then start a 1/4" nylock hex nut one or two turns onto

the link. See figure 7.

• Assemble the ferrule into the hole at the end of the

flow control lever using a 1/4" nylock hex nut.

Tighten

the nut, leaving it loose enough that the ferrule can

pivot freely. See figure 7.

• Assemble the grip onto the end of the flow control

lever. See figure 7.

FLOW

CONTROL

LINK

FERRULE

GRIP

FLOW

CONTROL

LEVER

1/4" NYLOCK

HEX NUT

1/4" NYLOCK

HEX NUT

1/4" NYLOCK

HEX NUT

• Assemble the hitch brackets to the hitch tubes using

two 5/16" x 2" hex bolts and 5/16" nylock hex nuts.

Do

not tighten.

See figure 5.

• Assemble the hitch pin through the hitch brackets and

secure with the hair cotter pin. See figure 5.

IMPORTANT: Do not

collapse the flat ends of the hitch

tubes when tightening the bolts in the next step.

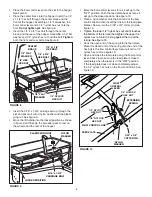

•

Tighten, but do not overtighten

the two 5/16" x

1-1/2" hex bolts assembled in figure 1.

Tighten, but do not overtighten

the two 5/16" x

1-3/4" hex bolts assembled in figures 2 and 3. The lift

handle must be able to pivot.

Tighten

the hex bolts assembled in figure 4 and 5.

• If the wheel does not spin freely, back off the nylock

jam nut and then the plain jam nut 1/4 to 1/2 turn each.

• Assemble a wheel to the other side. See figure 6.