4

ALWAYS

read and understand the

user manual before operating the

grinder.

MAKE SURE

you are wearing safety

glasses while operating the grinder.

The small particles becoming airborne

during grinding operation can seriously

damage your eyes.

ALWAYS

wear a dust mask or a

respirator while grinding. The dust

produced during grinding process can

lead to serious respiratory problems if

inhaled.

MAKE SURE

before making any

adjustments, servicing or installing

parts, the switch is in the “OFF”

position, and the cord is un-plugged

from the power source.

MAKE SURE

the RPM of the wheel

you are installing on the grinder is

equal to or higher than the speed of

the grinder. Operating wheels at a

higher speed than rated for may cause

the wheel to lie apart, fly or break.

MAKE SURE

to keep your hands at a

safe distance from the wheel.

NEVER LEAVE

the grinder unattended

while it is running.

MAKE SURE

to do a test on the

grinding wheels before installation.

Wheels that do not pass the test are not

safe to use. See page-8 for details.

ALWAYS

stand to the side of the

grinder when turning it ON and let the

wheel reach full speed. Stand at least

one minute to the side of the grinder

after startup. A damaged wheel can

break apart and fly shortly after starting

the grinder.

DO NOT

grind on the side of the wheel,

unless the wheel is rated for side

grinding.

ALWAYS

keep the tool rest within 1/8”

distance from the wheel while operating

the grinder.

MAKE SURE

you have read and

understood all the safety instructions in

the manual and you are familiar with

your grinder, before operating it. If you

fail to follow the instructions given in this

user manual, serious injury could occur.

WARNING

The safety instructions given above can not be complete because the environment in

every shop is different. Always consider safety first as it applies to your individual

working conditions.

CT171 - 10” WET BENCHTOP GRINDER

SPECIFIC SAFETY INSTRUCTIONS

Содержание CT171

Страница 1: ...CT171 10 WET BENCHTOP GRINDER User Manual ...

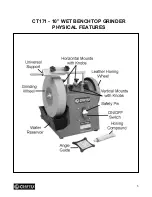

Страница 6: ...6 CT171 10 WET BENCHTOP GRINDER PHYSICAL FEATURES ...

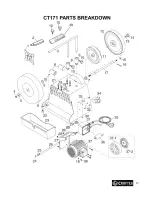

Страница 13: ...13 ...

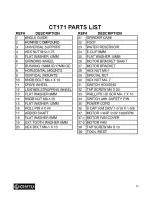

Страница 14: ...14 ...