- 8 -

b) Maintenance, service

The filter

must be checked and replaced regularly, at

least once a year. If the air filter is extremely dirty it

must be replaced more often.

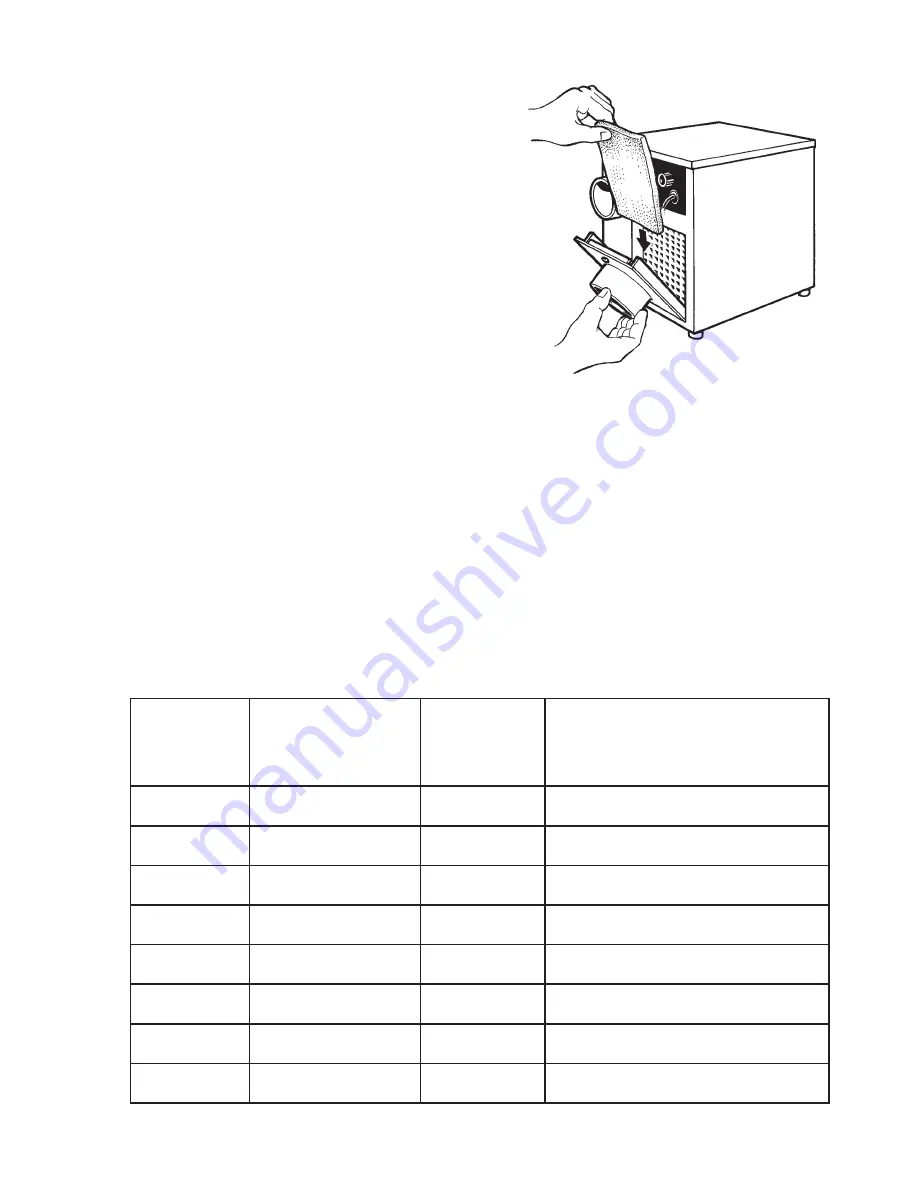

Open the filter door and replace the filter with a new

one.

c) Overheating

If the filter is very dirty or if the fan is broken, the

dehumidifier will stop because of overheating, which

causes the red warning lamp “operational stop” on

the control panel to light.

Allow the machine to cool and pull the electrical

plug out of the socket. If the machine has stopped because of a dirty filter it will run again

after replacing the filter, once the plug is connected to the socket.

If the dehumidifier does not restart or stops again because the fan is broken, contact the

installer.

d) Operation and service journal

Make notes of the filter changes in the table below. The operating hours reading is noted. Note

any action taken in conjunction with the filter change or other inspection in the column

"Notes".

Date

Run time meter

hours

Filter

replacement

Yes / No

Notes