19

MAINTENANCE SECTION

DISASSEMBLY

General Instructions

1. Do not disassemble the tool any further than

necessary to replace or repair damaged parts.

2. Whenever grasping a tool or part in a vise, always use

leather--covered vise jaws to protect the surface of the

part and help prevent distortion. This is particularly

true of threaded members and housings.

Always use leather--covered vise jaws when

clamping the handle in a vise. Leather will

conform to the shape of the handle and allow the

tool to be held securely. To prevent damage to the

exhaust diffuser, never clamp only the bottom of

the handle.

3. Do not remove any part which is a press fit in or on

a subassembly unless the removal of that part is

necessary for repairs or replacement.

4. Do not disassemble the tool unless you have a

complete set of new gaskets and O--rings for

replacement.

Disassembly of the Impact Wrench

1. Clamp the handle of the impact wrench in a vise with

leather--covered jaws with the square driver

positioned horizontally.

Avoid excessive clamping pressure which can

damage the Housing and can cause difficulty when

removing the parts.

2. Unscrew and remove the four Hammer Case Screws

(11).

3. While lightly tapping on the end of the Anvil (8) with

a plastic hammer, lift off the Hammer Case (15) and

Hammer Case Gasket (18).

The Front End Plate (2) might come off during the

removal of the Hammer Case. Make sure that it

does not drop on the floor or strike a hard or

metallic surface since it might be damaged.

4. Grasp the Hammer Frame (12) and carefully lift off

the entire impact mechanism, making certain not to

drop the two Hammer Pins (13).

Disassembly of the Impact Mechanism

1. Set the mechanism, driver end up, on the workbench.

Note the twin hammers within the Hammer

Frame. These are identical, but must be placed in

the Hammer Frame in a certain relationship. Using

a felt--tipped pen, mark

he top “T

↑

” hammer and

the bottom hammer “B

↑

” with the arrows

pointing upward. Mark both Hammers on the

same end.

2. With the mechanism sitting upright on the workbench,

slowly rotate the Anvil in a clockwise direction until

it comes up solid.

If you continue to rotate the Anvil, it will cam the

Hammers out of engagement. Don’t do this; merely

rotate the Anvil until it comes up solid.

3. Hold the Hammer Frame firmly and without

disturbing the hammers, gently lift the Anvil while

simultaneously rotating it clockwise about 1/8 of a

turn, from the Hammer Frame.

4. With the Anvil removed, lift out the two Hammer

Pins.

The twin hammers are now free to slide from the

Hammer Frame. Be careful do not to drop them.

Disassembly of the Motor

When pulling, disassembling or assembling the

motor, we recommend replacement of the Motor

Gasket (7).

1. Remove the Motor Assembly from the Housing (19)

by pushing on Power Management Dial (35) from the

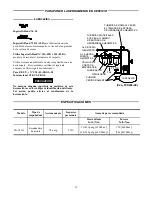

back of the Housing. Refer to Dwg. TPD1322.

POWER

MANAGEMENT

DIAL

(Dwg. TPD1322)

Содержание IR-C2131

Страница 27: ...27...

Страница 28: ...0402...