CSEES1KM 3 03/30/20

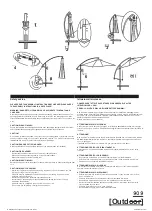

SETUP

Please refer to the exploded view drawing on page 5 in this manual in order to identify parts:

1. Insert the middle beam (#11) in the main post (#14) all the way until the ends of the square tubes are flush with each other and secure

them with a 3/4" long bolt (#10).

2. Secure the back leg (#3) to the angle iron portion of the main post (#14) and secure them together with the 2-3/4" long bolts (#9), flat

washers (#6), lock washers (#7) and nuts (#8).

3. Secure the front leg to the angle iron portion of the middle beam (#11) with the 2-3/4" long bolts (#9), flat washers (#6), lock washers

(#7) and nuts (#8).

4. Insert the two 3-1/2" diameter wheels (#1) into the bottom of the back leg (#3) and secure them to the leg with bolt (#2), washers (#5)

and nuts (#4).

5. Insert the two 3-1/2" caster assembly (#13) into the bottom of the front leg (#12) and secure them to the leg with bolt (#2), washers (#5)

and nuts (#4).

6. Install the tube section of the head mounting plate (#18) into the tube at the top of the main post (#14) and secure them together by

inserting the lock pin (#15) in the holes that line up between the two tubes.

7. Push one of the handle grips (#16) on the handle (#17) and insert the handle through the cross hole at the end of the head mounting

plate (#18). Now push on the remaining handle grip (#16) on the other end of the handle (#17).

8. Attach the four fingers (#22) to the head mounting plate (#18) with the 3" long bolts (#19), flat washers (#21), lock washers (#20) and

nuts (#23).

OPERATION

This is the safety alert symbol used for the

OPERATING INSTRUCTIONS

section of this manual to alert you to potential personal

injury hazards. Obey all instructions to avoid possible injury or death.

IMPORTANT:

Before attempting to raise any vehicle, check

vehicle service manual for recommended lifting surfaces.

1. Consult the vehicle or engine manufacturer for service manuals and/or technical bulletins that provide information on suggested engine

mounting tips, proper size and type mounting bolts and the engine's center of balance. The engine's center of balance will have to be

aligned with the rotational axis of the engine stand's mounting head.

2. Drain oil and coolant and remove clutch bell housing and flywheel from engine before mounting. Attach an engine lifting bar or sling to

the engine and secure the bar or sling to a shop crane or hoist. Slowly lift the engine from its compartment, making sure no other vehicle

components, wires or hoses obstruct the free movement of the engine. Raise the engine high enough so its center of balance is close to

the rotational axis of the stand's mounting head.

3. Make sure the four mounting head fingers are loosely connected to the mounting head plate. Secure the four mounting head fingers to

the bell housing end of the engine with the appropriate bolts and washers. Reposition the mounting head, fingers and engine so the

engine's center of balance is within one inch of the mounting head's rotational axis. Tighten all bolts to a sufficient torque requirement

that prevents any slippage.

4. Slowly lower the crane or hoist so the engine stand supports the full weight of the engine. To check engine balance and secure setup

of the engine to the stand, slowly rotate the engine by turning the handle. If balance or setup are not stable, rotate the engine to its

original position, raise the crane or hoist so the weight of the engine is removed from the stand, and make the correct adjustments. After

adjustments are made, tighten all bolts. This adjustment procedure may have to be duplicated several times until correct. After the setup

is balanced and secure, the lifting bar or sling can be removed from crane or hoist.

5. To remove the engine from the stand, connect the lifting bar or sling to the crane or hoist and raise the engine high enough to take

the weight off the stand. Carefully remove the bolts that connect the four mounting fingers to the engine. Be aware there will be a slight

movement of the stand as total engine weight is transferred to the crane or hoist.

PREVENTATIVE MAINTENANCE

This is the safety alert symbol used for the PREVENTATIVE MAINTENANCE section of this manual to alert you to potential

personal injury hazards. Obey all instructions to avoid possible injury or death.

1. Always store the engine stand in a well protected area where it will not be exposed to inclement weather, corrosive vapors, abrasive

dust, or any other harmful elements. The stand must be cleaned of water, snow, sand, grit, oil, grease or other foreign matter before

using.

2. Lubricate the wheels, casters, zerk fittings, gear and rotating shaft with a general purpose grease.

3. Every stand owner is responsible for keeping the device labels clean and readable. Use a mild soap solution to wash external surfaces

of the device. Contact Cornwell Tools for a replacement label if the device's label is not readable.

INSPECTION

Visual inspection should be made before each use of the engine stand, checking for damaged, loose or missing parts. Each engine stand

must be inspected by a manufacturer’s repair facility immediately, if subjected to an abnormal load or shock. Any stand which appears to

be damaged in any way, is found to be badly worn, or operates abnormally MUST BE REMOVED FROM SERVICE until necessary repairs are

made by a manufacturer’s authorized repair facility. It is recommended that an annual inspection of the stand be made by a manufacturer’s

authorized repair facility and that any defective parts, decals or warning labels be replaced with manufacturer’s specified parts. A list of

authorized repair facilities is available from the manufacturer.

CSEES1KM

750 LB.

ENGINE STAND