The oil pressure should be about 20 psi (1.4 bars) minimum

for normal service. If the compressor discharge pressure

is above 200 psi (14.8 bars), the oil pressure must be

maintained at a minimum of 25 psi (1.7 bars). A spring-

loaded relief valve mounted on the bearing housing opposite

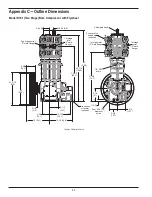

the flywheel regulates the oil pressure. As shown in figure

2.3, turn the adjusting screw clockwise to increase the

oil pressure and counterclockwise to lower it. Be sure to

loosen the adjusting screw locknut before trying to turn the

screw and retighten it after making any adjustment.

Oil filter

Oil pressure gauge

Breather cap

Oil pressure

relief valve and

adjustment screw

Figure 2.3: Oil pressure adjustment

2.4 Startup Check List

Please verify each item on this list below before

starting your compressor!

Failure to do so may result

in a costly (or dangerous) mistake.

Before Starting the Compressor

1. Become familiar with the function of all piping

associated with the compressor. Know each line’s use!

2. Make certain actual operating conditions will match the

anticipated conditions.

3. Ensure line pressures are within cylinder pressure

ratings.

4. Clean out all piping.

5. Ensure all distance piece openings are tubed or

plugged as desired.

6. Check all mounting shims, cylinder and piping supports

to ensure that no undue twisting forces exist on the

compressor.

7. Make certain strainer elements are in place and clean.

8. Make certain cylinder bore and valve areas are clean.

9. Check V-belt tension and alignment or drive alignment

on direct drive units.

10. Rotate unit by hand and make certain there is no

wobble or play.

11. Check crankcase oil level.

12. Drain all liquid traps, separators, etc.

13. Verify proper electrical supply to motor and panel.

14. Check all gauges and confirm a zero level reading.

15. Test piping system for leaks.

16. Purge unit of air before pressurizing with gas.

17. Carefully check for any loose connections or bolts.

18. Remove all stray objects (rags, tools, etc.) from vicinity

of the unit.

19. Confirm all valves are open or closed as required.

20. Double-check all of the above.

After Starting Compressor

1. Verify and note proper oil pressure. Shut down and

correct any problems immediately.

2. Observe noise and vibration levels. Correct immediately

if excessive.

3. Verify proper compressor speed.

4. Examine entire system for gas or oil leaks.

5. Note rotation direction.

6. Check start-up voltage drop, running amperage and

voltage at motor junction box (not at the starter).

7. Verify proper lubrication rate (lubed units only).

8. Test each shutdown device and record set points.

9. Test or confirm set point on all relief valves.

10. Check and record all temperatures, pressures and

volumes after 30 minutes and 1 hour.

11. After 1 hour running time, tighten all head bolts, valve

holddown bolts, and baseplate bolts. See Appendix B

for torque values.

10

Содержание D791

Страница 27: ...Appendix C Outline Dimensions Model D891 Single Stage with 107B Mounting Inches Centimeters 27 ...

Страница 33: ...33 ...

Страница 51: ...51 ...