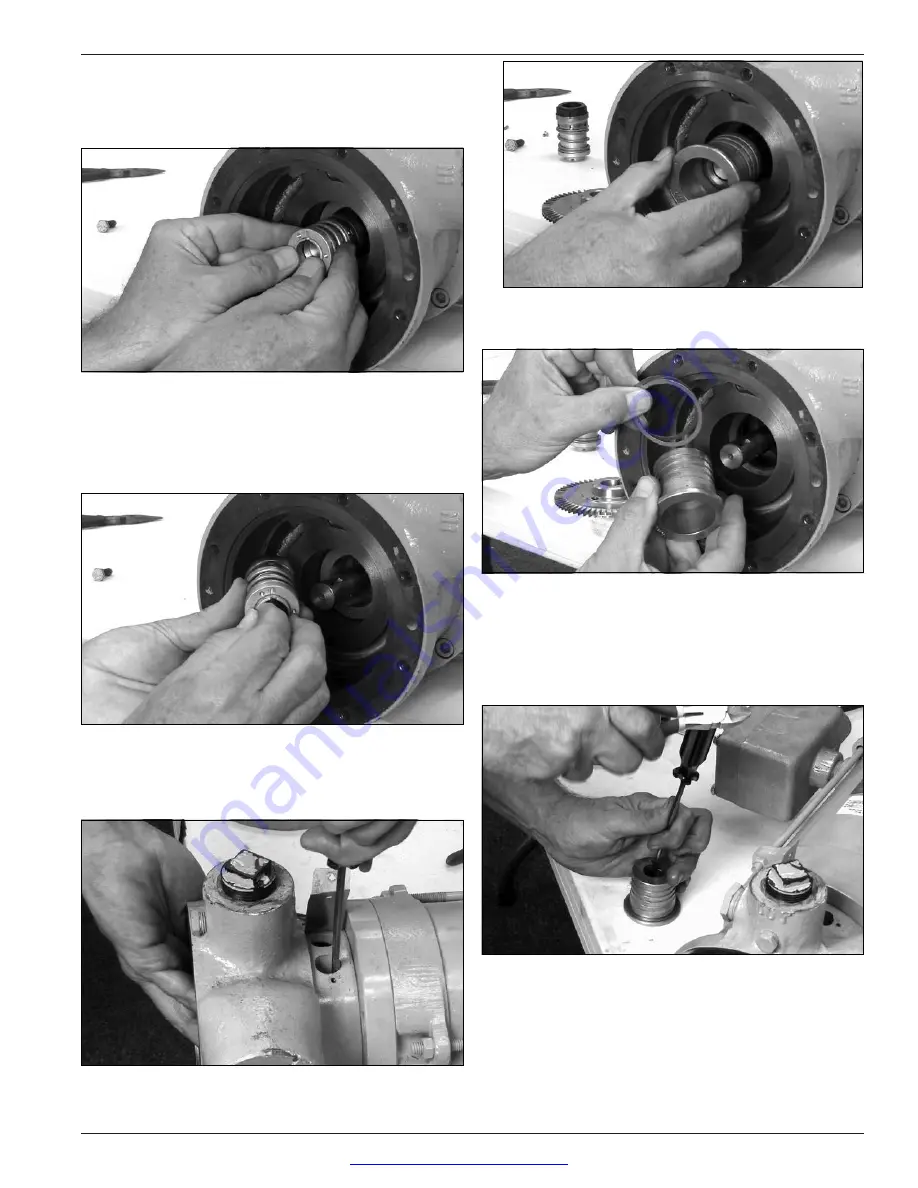

the shaft so the locking pin is in the 6 o’clock position.

Compress the seal assembly with your thumbs and the

pin should drop out. A light press with a screwdriver

may help if the seal assembly does not move back.

15. Reach in with your fingers and remove the sleeve, follower,

and follower O-ring. If there are any nicks or burrs on the

shaft, removal may be difficult. Push the assembly back

in and use emery cloth to smooth and polish the shaft.

Repeat until the sleeve assembly slides out easily.

16. After you remove the assembly note the follower and

follower O-ring. The O-ring is compressed by the follower

when you tighten the seal clamp ring with the 3 screws. It is

critical that the shaft is smooth and clean for a positive seal.

17. To access the seal housing, remove the nameplate

located at the top of the pump casing and insert a flat

blade screwdriver in the opening.

Pry the seal housing forward with the screwdriver and

remove the housing from the pump.

18. After the seal housing has been removed, locate

and remove the shims behind the flange of the seal

housing. Make sure no shims have stuck to the inside

of the casing. Note the number of shims and set aside.

These shims will be re-used during reassembly and

are critical for proper seal compression.

19. Remove the metal stationary seat inside the seal

housing by placing the seal housing face down on a

flat work surface. Lightly tap the seat with a flat blade

screwdriver until it drops out. Or, using a small flat

blade screwdriver, gently pry the seat, rotating the

housing, until the seal drops out.

13

www.northridgepumps.com