MAN1

CANCEL

LOAD/EJ

STOP

START

MENU

Printi

The Qu

you wit

set. Th

and prin

1. Each

2. Each

selec

3. Ensu

STO

4. Pres

Dow

5. Pres

comes

Test be

6. Wait

off

7. Pres

should

YOU H

THE PR

We rec

Save th

printer c

1.Press

printer d

To exit

CANCE

Press

E

the Use

Confi

See the

make a

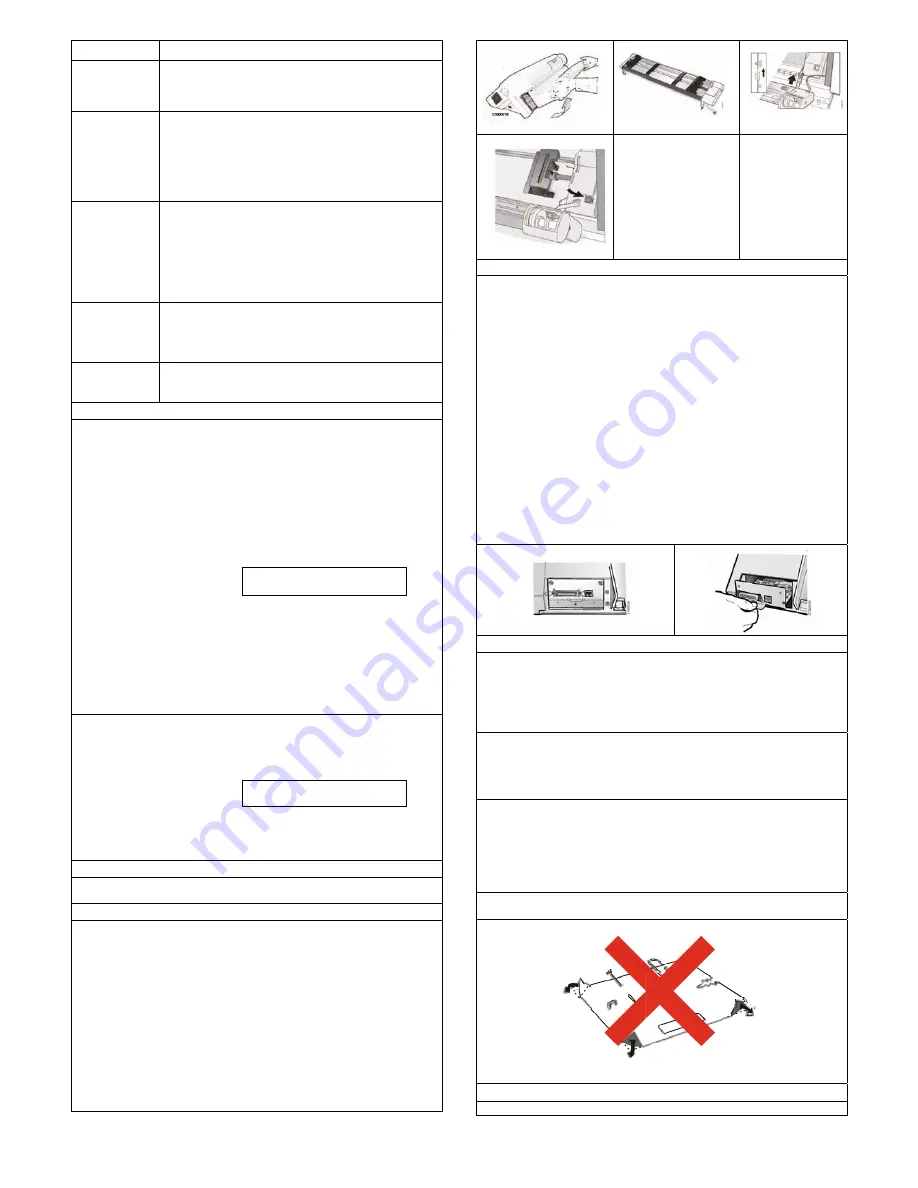

Instal

A secon

be insta

1.Open

2.Unpa

3.Align

the fir

engag

4.Conn

cable

5.Rotat

6.Rotat

7.To loa

installed

two trac

10293R01

Press

continu

When

attachm

For an

data a

ready.

JECT

The LO

have s

paper

The LO

-Autom

senso

LOAD

positio

- Move

If the p

-Make

disapp

-Stop p

-Stop a

-Stop t

-Allow

appea

-Clear

-Stop t

Press

-Make

the op

-Exit t

reset

effect

Use th

functio

and no

paper

ng the First

uick Reference

h the operator p

e Quick Refere

nter operations.

h key is listed wi

h parameter is s

ct printed to the

ure that the print

P

to make the p

s

TEST

Press

S

wn

until the printe

ss

ENTER

or

S

on and printing

efore it complete

t for the printer

f.

s

FORM FEED

be clear and re

HAVE JUST CO

RINTER.

ommend that yo

his printout for fu

configuration by

s

SCROLL/MIC

displays:

Print Test, pres

EL PRINT

to ma

ENTER

or

STA

er's Guide for m

guring the P

e User's Guide o

and save printer

lling the opt

nd optional trac

alled on the first

n the tractor area

ck the second t

the hooks on b

rst tractor. Push

ged.

ect the second

e/connector prov

te the tractor ge

te the second tra

ad paper onto th

d, rotate the sec

ctors.

SET TOP OF FO

uous paper sources o

this key is pressed

ment sends a “cance

ny attachment option

and buffers. This fun

OAD/EJECT functio

selected. This sectio

paths.

OAD/EJECT key perf

matically loads forms

or and onto the tracto

D/EJECT to automa

on.

es forms to the tear-o

printer is in a ready st

the printer not re

pear from the operato

printing as soon as p

a test if the printer is

the printer alarm from

you to use the other

ars on the operator p

the error message fr

the printer alarm from

START to perform t

e the printer ready an

perator panel display

the Configuration Me

is required, it is pe

before the printer be

he Menu function k

on key is valid when t

o job is in progress

movement functions

t Document

is a popular pr

panel keys and

ence printout a

.

ith a correspond

shown with the c

right.

ter is off line. If

printer not ready

SCROLL/MICRO

er displays:

OP

Qui

START

to print

g begins. Press

es printing.

to stop printing

until you can re

adable.

OMPLETED A

ou now print yo

uture reference.

y following these

RO Up

or

SCRO

OP

Prin

ss

RETURN

to m

ake the printer r

ART

to print this

more information

Printer

on the CD-ROM

r configuration s

tional secon

tor is available f

t (standard) fron

a cover.

tractor.

oth sides of the

h the second tra

tractor to the fir

vided on the trac

ear protection co

actor into the cl

he first tractor w

cond tractor out

ORM to set the to

only.

while the printer is

el request” to the hos

n, the CANCEL PRIN

nction is valid only

on depends on wha

on describes the fu

forms the following fu

After the forms are l

ors at the bottom of

tically load the form

off position

tate, press STOP to:

eady and cause the

or panel display

possible without losin

in test mode

m beeping

r printer function keys

anel display, press S

rom the display

m beeping.

he following function

nd cause the READY

.

enu and make the p

erformed to put con

ecomes ready.

key to enter the Co

the printer is not read

s. After you enter t

are not available.

rint test that ma

the configurati

allows you to c

ding description

corresponding v

the printer is rea

y

O Up

or

SCRO

ERATOR PRIN

ick Reference

t this test. The

STOP

if you w

g and the READ

emove the printo

SETUP AND

ur printer config

. You can create

e steps:

OLL/MICRO Do

ERATOR PRIN

nt Customs Se

make the printe

ready.

s test. See “Prin

about this print

M for information

setting changes

nd tractor

for your printer.

nt tractor.

e second tractor

actor on the pins

rst using the ele

ctor.

over downwards

osed operating

when the second

tstands insert pa

p of form position

active and on line,

t.

NT button clears all p

when the printer is

t active form path y

unction for each of

unctions:

oaded under the

the forms device pr

ms to the top of fo

e READY message

g print data

s If an error condition

STOP to:

s:

Y message to appea

printer ready. If a pa

nfiguration changes

onfiguration Menu. T

dy or the printer is re

he Configuration Me

ay help familiari

on menu you c

heck print qual

n to the right.

values you can

ady, press

LL/MICRO

NT TESTS

READY indica

want stop the P

DY indicator to

out. The printou

CHECK OUT

guration defaults

e a printout of th

own

until the

NT TESTS

ets

r not ready or

nt Custom Sets”

tout.

n about how to

This tractor ma

with the pins on

s until it is fully

ectrical

s to free the gea

position.

d tractor is

aper between th

3

for

, the

s not

you

the

ress

orm

e to

n

aring

artial

into

This

eady

enu,

ize

can

lity

ator

go

ut

OF

s.

he

” in

ay

n

ar.

he

R

Th

Th

ins

ca

At

pa

yo

At

re

1.

re

the

2.

in

3.

se

co

ali

4.

the

M

Pe

wi

1.

2.

3.

pr

Cl

Ev

du

pr

du

Cl

Cl

no

Do

sta

Do

be

At

to

P

Us

S

Removing an

he printer is ship

he following op

stall a new one

an be used.

ttention

: Do no

ackage until inst

ou, can damage

ttention

: Ensur

moving the Con

Use the screwd

move the contr

e two screws.

Align the left a

the printer and

Gently push t

eated in the co

orrectly seated i

igned with the b

Firmly fix the C

e screwdriver th

Maintenance

eriodic cleaning

ll always provid

Turn off the pri

Unplug the pow

Wait at least 15

rocedure

leaning inside

very few months

ust, ribbon lint, a

revent the ribbon

ust from around

leaning the out

ean the outside

ot use any spray

o not put any liq

ains on the cove

o not use an ab

ecause they ma

ttention

: Do no

fall inside the p

roblem Solv

sing status cod

C

Pin

Staple

nd Installing

pped with the co

perations explai

into the proper

ot remove the

tructed to do so

sensitive Contr

re that the print

ntroller Board.

driver that came

roller board on

nd right sides o

slide it into the

the new Contro

onnector inside

n the printer wh

back profile of th

Controller Board

hat came in the

- Cleaning t

will help keep y

e optimal perfo

nter.

wer cord.

5 minutes for the

the Printer

s, use a soft bru

and pieces of pa

n from going int

the print head a

tside covers

e of the printer w

y-type or chemic

quids or spray ne

er, use a comm

rasive cloth, alc

y cause discolo

t allow any stap

printer.

ving

de and problem

Clip

T

Foreign

material

g the Contro

ontroller board a

in how to rem

r slot in the bac

Controller Boa

o. Static electric

roller Board com

ter is powered

e in the Controll

the back of the

of the Controlle

slot.

oller Board into

the printer. T

hen the Control

he slot.

with the two ca

Controller Boar

the printer

your printer in to

ormance. Before

e printhead to c

ush and a vacuu

aper. Remove th

to the vacuum c

and in the printe

with a damp clot

cal cleaners any

ear the air vent

mercial mechanic

cohol, paint thin

oration or scratc

ples, paper clips

m listings

4247X03Plu

Fol

Tear

oller Board

already installed

ove the contro

k of the printer

ard from the pr

city, though harm

mponents.

off before inst

er Board box to

e printer by uns

r Board with the

o the printer u

he Controller B

ler Board metal

aptured screws

rd box.

op condition so

e you clean the p

cool before start

um cleaner to re

he ribbon cartrid

cleaner. Vacuum

er cavity.

th and mild soap

ywhere on your

s. For stubborn

c's hand cleane

ner, or similar a

ching.

s, or small meta

us

‐

QSG

d.

oller and

before it

rotective

mless to

talling or

o

screwing

e guides

until it is

Board is

l plate is

using

that it

printer:

ting this

emove

dge to

m any

p. Do

r printer.

ink

r.

agents

l pieces