MAN10293R01

2

4247X03Plus

‐

QSG

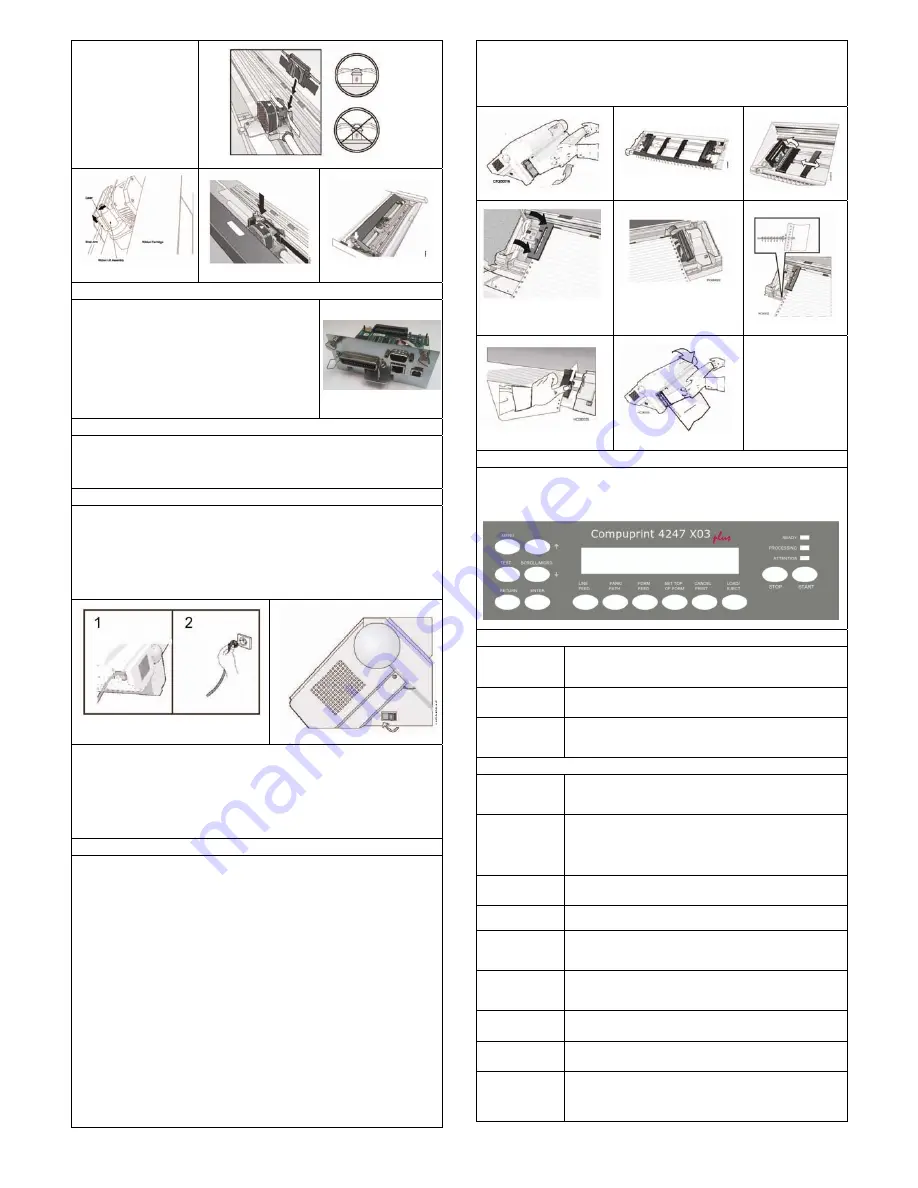

The ribbon must be

between the print

head noose and the

mask.

Host Computer Connection

There are two types of Controller Boards:

1.Controller Board with a bidirectional

IEEE1284 parallel interface, Serial RS-

232/DB9, USB 2.0 and ASCII Ethernet

10/100 BaseT LAN interface.

2. Controller Board with a bidirectional

IEEE1284 parallel interface, Serial RS-

232/DB9, USB 2.0 and IPDS

Ethernet10/100 BaseT LAN interface.

Software Driver Selection

At this point it is necessary to configure your printer for your application

package. The installation procedures depend upon the host

environment. In a Windows® environment, the printer supports the

Plug&Play feature.

Power Connection

1. Make sure the power outlet is near the printer location and

easily accessible.

2.Make sure that the power switch is in 0 position(OFF).

3.Insert the power cable plug into the printer connector and the

other power cable end into a convenient outlet.

4.Turn the printer on, press the power switch in the position (ON).

Attention

: Use always wall oulet with ground wire.

Attention

: If, for any reason, the Controller Board was not correctly

installed in the printer, the printer will not work and the following

audio/visual symptoms will occur:

- The buzzer sounds continuously.

- The Operator Panel display is partially filled with solid black boxes.

- The Operator Panel LEDs are all lit. If this is the case, power off the

printer, re-seat the Controller Board, and power the printer on again.

Loading Fanfold Paper

This sequence describes how to load the fanfold paper with the push

tractor (default). For the other paper paths please see the User's

Guide you find on the CD Rom.

1.Turn the printer on.

2.Open the Push tractors cover turning it upwards and lay it on the top

of the printer.

3.Unlock the tractors by moving the sprocket levers up. Slide the left

tractor to the left.

4.Space the paper guides along the tractor bar. Open the left and right

sprocket covers.

5.Hold the fanfold paper in front of the sprockets and insert the paper

perforation on the left sprocket pins and close the left sprocket cover.

6.Insert the paper on the right sprocket pins.

7.Match the left sprocket for the first printing position, that is the left

margin must match the 9

th

mark on the printer cabinet. Note:

Aligning the left-hand edge of the paper past the 22

nd

spacer on the

printer cabinet will cause the paper to be misaligned with the Paper

Load Sensor resulting in a '001 End of Forms' error.

8.Adjust the right sprocket gently to remove slack from the paper.

Lock the left and right sprockets moving the sprocket levers to the

up position.

9.Close the Push tractors cover.

10.Press the

STOP

key to take the printer Not Ready.

11.Press the

LOAD/EJECT

key to load the paper into the printer.

12.Press the

START

key to put the printer Ready.

Operator Panel

The operator panel contains 3 status indicators, a 2-line by 24-

characters display panel, 14 printer function keys, and an audible

alarm as indicated in the figure below. For indicators and function keys

there is a short description. For details see User’Guide.

Indicators

READY

If the READY indicator is lighted, the printer is ready to print. If READY

is not lighted, the printer is not ready to print.

The printer can receive data when this indicator is not lighted, but no

data can be printed.

PROCESSING

If lighted, the printer is printing or processing data. If blinking, the

printer buffer contains data that cannot be printed immediately. If not

lighted, there is no data to process and no data in the print buffer.

ATTENTION

If blinking, the printer requires operator intervention (for example, to

add forms or to clear a forms jam). The type of intervention needed

appears on the display panel. If not lighted, the printer does not require

immediate attention.

Keys

MENU

Use the Menu function key to enter the Configuration Menu. This

function key is valid when the printer is not ready or the printer is ready

and no job is in progress. After you enter the Configuration Menu,

paper movement functions are not available.

SCROLL/MICRO

↑

SCROLL/MICRO

↓

Use SCROLL/MICRO or SCROLL/MICRO to perform the following

functions:

- Adjust forms upward or downward when the printer is not ready.

- Scroll through the Configuration Menu categories, parameters,

and values.

- Scroll through the Operator Print Tests menu items.

TEST

Press TEST to enter the Operator Print Tests menu. The Test function

is valid only when the printer is not ready. There are several tests

available.

RETURN

Pressing RETURN in the Configuration Menu returns to the previous

level of the menu.

ENTER

The Enter function is available when the Configuration Menu or

Operator Print Tests Menu is displayed. Pressing ENTER selects the

displayed option. The Enter function is also used during some of the

tests.

LINE FEED

Press LINE FEED to cause the printer to advance the forms one print

line, based on the current LPI setting. If you hold LINE FEED more

than four seconds, the forms move continuously until you release the

key.

PARK/PATH

Pressing this key causes the printer to enter the Park function in either

the ready and not ready state. The continuous forms will backup

(reverse the process direction of) the forms in the forms path.

FORM FEED

This key advances the forms so that the next form is at the top of form

position. The Form Feed function is available when the printer is not

ready.

SET TOP OF

FORM

This should only be used when printing occurred and no Top-of-Forms

commands have been passed to the printer (such as Form Feed or

Printer initialization). The Set Top of Form function is available only

when the printer is not ready, and the paper is loaded to the print line.

This key can be used only for the continuous forms paper sources.