5. Extended functions

13

If there are no days of the week selected in the

switching unit line, the switching unit is not active. The

switching unit only becomes active when the day of the

week is set. When the

is pressed, the first

underscore _ starts to flash. You can now use the

key to set the first day of the week (Sunday). Then use

the

key to confirm the day of the week. The next

underscore _ then starts to flash. If you do not want to

confirm a day of the week as set, please immediately

press

.

You can run through all seven days of the

week in this way. Once you have confirmed the last day

of the week (Saturday), the first unit of the switch-in -

point starts to flash. You can either set this using

or

. Once the last unit of the switch-out point has been

confirmed, the whole timer unit is activated.

The next step is to go to the

[

CONTROL

MENU

]

sub-

menu and then the

TIMER

CONTROL

menu item. You

will now see the default setting

TIMER

CONTROL

OFF

.

If you press the key, the

OFF

value starts to flash.

You can now use the

key to change the value to

ON

. Then please press the key again to confirm the

entry. The timer is now switched on.

To improve your understanding of this function, the

timer unit setting is explained below using various

examples.

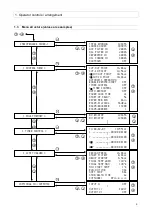

Example 1:

Switching unit 1 not active:

1 _______ 00:00 00:00

Example 2:

The unit should run Monday to Friday between 7.30 am

and 4.15 pm.

2 _MTWTF_ 07:30 16:15

a)

b)

c)

a) Days of the week Monday to Friday

b) Switch-in point

c) Switch-off point

Example 3:

The unit is to run from Sunday 10 pm through

continuously to Saturday 2 pm. However during the

daily break (12 midday to 12.30 pm), the unit is to be

shut down.

You will now have to use various switching units. The

following settings would be needed in this case:

1 S______ 22:00 00:00

a)

2 _MTWTFS 00:00 12:00

b)

3 _MTWTF_ 12:30 00:00

c)

4 ______S 12:30 14:00

d)

5 _______ 00:00 00:00

6 _______ 00:00 00:00

7 _______ 00:00 00:00

a) Start of operating period

b) Operating period up until lunch break

c) Start of operation after lunch break

d) End of operating period

5.3.2 Pressure changeover setting

Please go to the

[

TIMER

CONTROL

]

sub-menu. There

you can use

or

to select between various timer

units. The timer units of the 2nd (

p

2

) pressure range are

in the menu under the normal timer units.

CUT-OUT POINT

CUT-IN POINT

p2 CUT-OUT

p2 CUT-IN

p2 TIMER CONTROL

ON-LOAD

Fig. 2 Pressure changeover block diagram