CompAir UK Ltd

PUBLICATION 98407/1050

Page 21

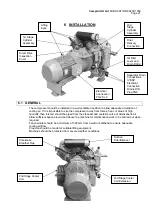

6 INSTALLATION

6.1 GENERAL

The compressor should be installed in a well ventilated position to allow adequate circulation of

cooling air. If it is impossible to site the compressor away from fumes, heat, or areas of high

humidity, then inlet air should be piped from the cleanest and coolest source of atmospheric air.

Allow sufficient space around and above the machine for maintenance work to be carried out when

required.

Fan cowl inlet should be a minimum of 300 mm from a wall or bulkhead to ensure adequate

cooling air-flow.

Provision should be made for suitable lifting equipment.

Machines should be protected from severe weather conditions.

Lifting

Eyes

Final

Delivery

Connection

Electrical

Connection

PG 29 x 2

Separator Drain

Connections

½"BSP.

Electrical

Connection

Drains DIN

Plug PG9

Direct Drive

Inspection

Cover

2nd

Stage

Cylinder

Assembly

1st Stage

Cylinder

Assembly

Oil Filler,

Level and

Drain Fitting

Suction

Filter/Silencer

Crankcase

Breather Pipe

2nd Stage Cooler

Coil

2nd Stage Cooler

Coil Extension

Содержание 5211.2.IA

Страница 2: ......

Страница 14: ...CompAir UK Ltd PUBLICATION 98407 1050 Page 12...

Страница 16: ...CompAir UK Ltd PUBLICATION 98407 1050 Page 14 REMARKS DATE REMARKS DATE...

Страница 22: ...CompAir UK Ltd PUBLICATION 98407 1050 Page 20...

Страница 32: ...CompAir UK Ltd PUBLICATION 98407 1050 Page 30...

Страница 38: ...CompAir UK Ltd PUBLICATION 98407 1050 Page 36...

Страница 61: ......