T

echnical

i

nformaTion

SPECIFICATIONS

U S C U S T O M E R S U P P O R T 1 - 8 8 8 - 6 2 2 - 2 3 7 7 | W W W. C O M M A N D A C C E S S . C O M | C A C U S T O M E R S U P P O R T 1 - 8 5 5 - 8 2 3 - 3 0 0 2

Select your preferred torque mode (ships in standard torque) Press the device push pad

to the desired setting. (Recommend to fully depress and release 5%, giving the device

room for changing door conditions.)

Step 2-

While depressing the push pad, apply power. (i.e. presenting the credential to the reader).

Step 3-

Continue to keep pad depressed, the device will beep 6 times. After the beeps have stopped,

release the pad and now the adjustment is complete. If not to your liking repeat the 3 steps.

Step 4-

Once you found the correct location, turn PTS switch to OFF position.

Setting PTS

**Important Info**

Make sure to set PTS before finishing installation

Step 1-

Troubleshooting & Diagnostics

Beeps Explanation

Solution

Average Latch Retraction Current: 2 A

Average Holding Current: 250 mA

High Torque Mode

Average Latch Retraction Current: 1.3 A

Average Holding Current: 215 mA

Standard Torque Mode

MM4 Switches

ON

ON

OFF

STANDARDTORQUE

HIGH TORQUE

PTS Programing Lock

PTS PROGRAMING On

OFF

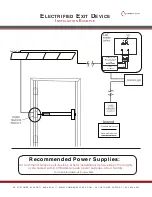

• Input Voltage: 24VDC +/- 10%

• Wire gauge: Minimum 18

gauge

• Direct wire run - no relays or

access control units in-between

power supply & module

1

2

2 Beeps

3 Beeps

5 Beeps

6 Beeps

Over Voltage

Under Voltage

Retraction or Dogging

failure

Push to Set

> 28V unit will shut down. Check voltage & adjust to 24 V.

< 22V unit will shut down. Check voltage & adjust to 24 V.

Device physically binding during retraction or pulled from the dogged position.

Device is recording it’s new position and power mode after the 6th beep.

4 Beeps

Failed Sensor

Verify all 3 sensor wires are installed correctly. Replace sensor if problem

persists by contacting office.

1. After 1

st

fail: 5 beeps then immediately attempts to retract again.

2. After 2

nd

fail: 5 beeps with pause in-between for 30 seconds then

device attempts to retract again.

3. After 3

rd

fail: 5 beeps every 7 minutes, device will not attempt to retract.

To Reset: Depress bar for 5 seconds at any time.