First issue 10/14

Release A10/14

PGRF

5/9

To guarantee long life and excellent performance to the gear unit, maintenance opera-

tions must be done on a regular basis.

Before

maintenance operations, authorized people must disconnect the unit power supply,

putting it “out of order”, taking all the necessary precautions to ensure it cannot be restar-

ted accidentally or any of its moving parts.

During

maintenance operations:

•

it is forbidden to work with machines in movement,

•

wear suitable protection (IPG),

•

avoid accidental restart of the unit ,

•

oil leaks should not be a source of danger,

•

do not handle units that are still very hot.

ORDINARY MAINTENANCE

includes:

•

check of oil level and oil leaks,

•

oil topping off,

•

oil replacement,

•

grease topping off,

•

periodical inspection

.

EXTRAORDINARY MAINTENANCE

include:

•

disassembly and reassembly;

•

replacement of wearing or damaged parts;

•

bearing replacement;

•

oil seals replacement.

MALFUNCTION AND ANOMALIES

When

malfunctions/anomalies are found:

•

schedule an immediate/anticipated general overhaul;

•

replace damaged or faulty components with new components if necessary.

MAINTENANCE

When

maintenance operations

are

finished

, restore all

safety conditions of

functioning

Note:

Instruction for

extraordinary maintenance

are NOT described

in this manual

Note:

described

maintenance intervals

could be different with

different machine duty

cycle

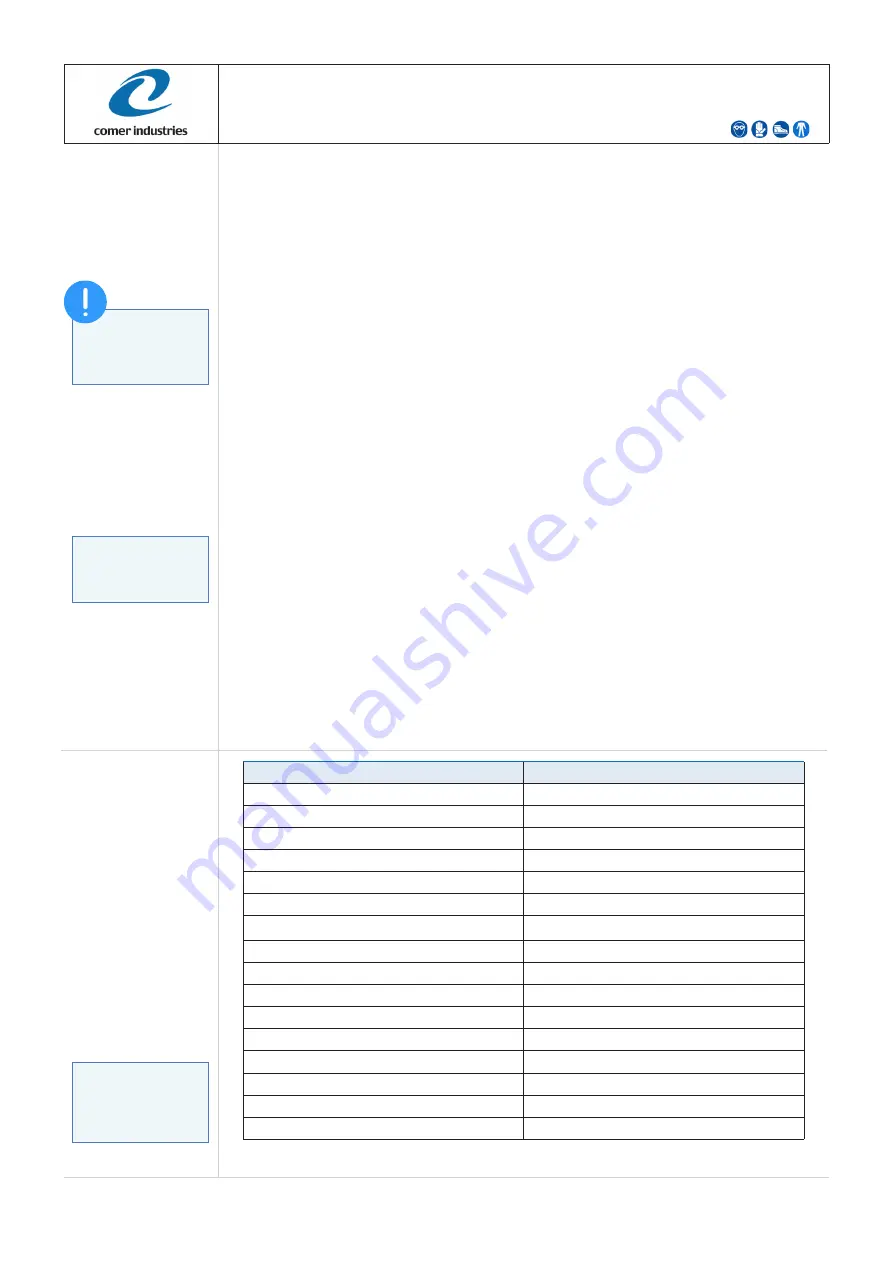

MAINTENANCE

INTERVALS

Inspection and Operations

Intervals

Oil leakage

before functioning

Brake functioning

before functioning

Oil and surface temperature

on functioning

Noise and vibrations

on functioning

FIRST OIL CHANGE

only after initial 100 service hours

Oil level check

every

500

service hours or monthly

Unit and plugs cleaning, oxidation, damage

every

500

service hours

ORDINARY MAINTENANCE

every

2000 service hours

or at least once a year

Oil replacement

ordinary maintenance

Presence of water in the oil

after oil draining

Brake test

ordinary maintenance

Screws/plugs tightening torque

ordinary maintenance

EXTRAORDINARY MAINTENANCE

every 5000 service hours

Oil seals replacement

extraordinary maintenance

Bearings replacement

extraordinary maintenance

Brake disks and springs replacement

extraordinary maintenance

ORDINARY MAINTENANCE

Maintenance operations must be carried out by qualified, trained and authorised personnel