33

P/N: 192047082 (REV AD) 627NH

March 2022

VARIABLE SPEED ELECTRIC CHAIN HOIST WITH

OPTION

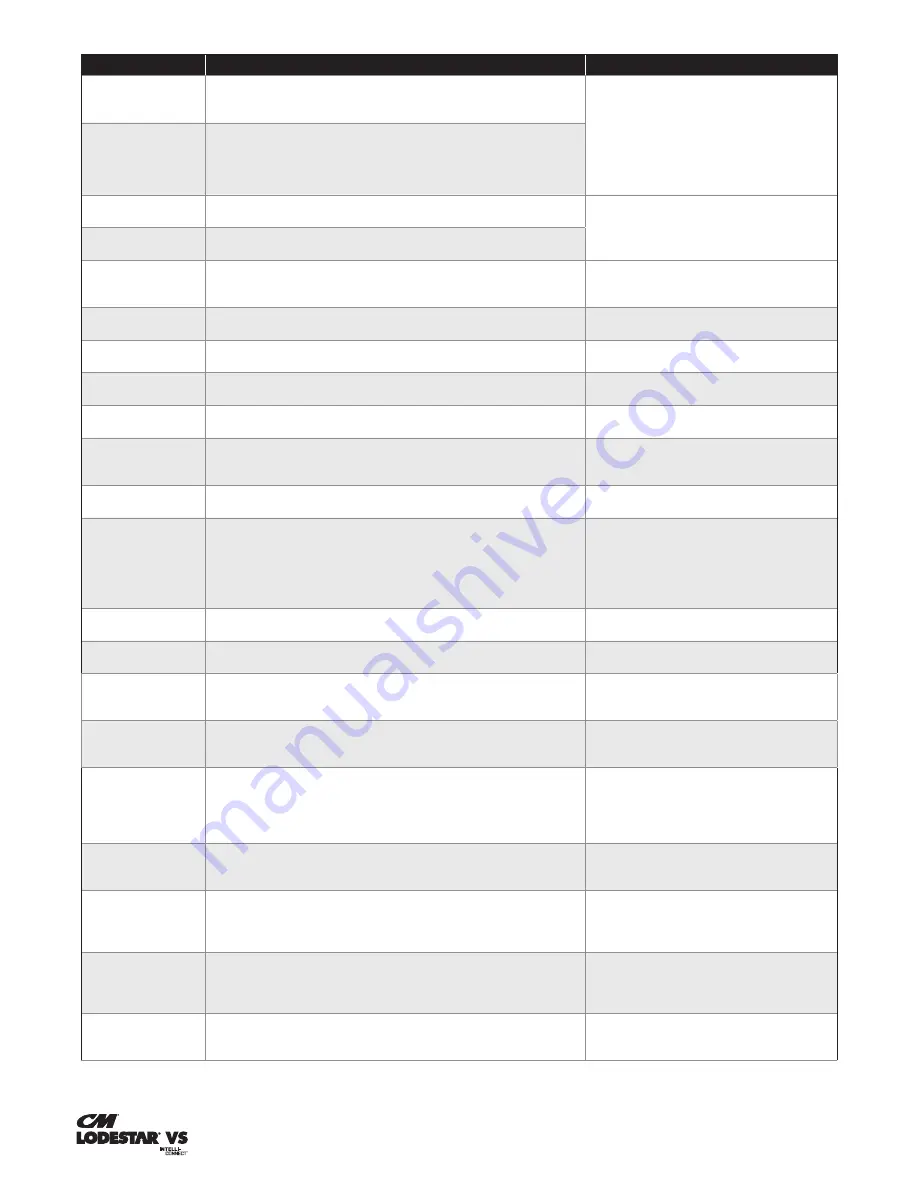

Fault Code

Fault or Indicator Name/Description

Corrective Action

OH1

Heatsink

MaxTemp

Overheat Fault. There are two situations that result in an overheat fault. The first

occurs when the measured heatsink exceeds 105°C. The second is the result of a

fault in the internal 24VDC cooling fan.

1.

Ensure that the heatsink cooling fans are

functioning.

2. Ensure that the heatsink is free from dirt and

debris.

3. Ensure that the inverter’s ambient temperature is

within specifications.

4. Replace the 24 VDC fan.

5. Replace the heatsink thermistor(s).

OH2

(Flashing)

Overheat 2

Overheat Alarm. Signal is input by external terminal. H01.XX = 39

OH3 Motor

Overheat 1

Motor Overheating 1. Thermistor analog input detects motor overheating.

See L01.03.

1. Check the motor rated current value, E02.01.

2. Increase cycle time OH4 Motor or reduce the load.

OH4 Motor

Overheat 2

Motor Overheating 2. Thermistor analog input detects motor overheating.

See L01.04.

OL1

Motor

Overloaded

Motor Overload Fault. Inverter output exceeds the inverter overload level.

1. Ensure drive is programmed with proper motor full

load Amps (E02.01).

2. Reduce the load.

OL2

INV Overload

Inverter Overload Fault. Inverter output exceeds the inverter overload level.

1. Reduce the load.

2. Extend the acceleration time.

OPE01

kVA Selection

kVA Settings Fault. Inverter kVA setting range is incorrect.

1. Check O02.04 constant for proper kVA.

OPE02

Parameter Range Setting Error. Parameter settings are set outside the

parameter range.

1. Press enter to view parameter.

2. Change parameter to appropriate setting.

OPE03

Terminal

Multi-Function Input Settings Fault. Set values other than F and FF

are duplicated.

1. Check the settings for H01.01 to H01.07. Verify that

the same input is not used twice.

OPE04

Terminal

Parameters do not match. The drive, control board, or terminal board has been

replaced, and the parameter settings between the controll board or terminal board

do not match.

1. Press ENTER to view the parameter.

2. Change parameter(s) to appropriate settings.

3. Set A01.05 = 5550.

OPE07

Analog Selection

Multi-Function Analog Input Setting Fault. Set values other than 00 and 0F

are duplicated.

1. Check setting for H03.02 and H03.10. Verify that

the same value is not used twice.

OPE08

Terminal

Selection Parameter error. A parameter has been changed that is not available

in the present control method.

1. Undo the last parameter change (if known).

2. Scroll through modified constants for obvious

setting error.

3. Perform a user initialize (A01.05 = 1110).

CAUTION: All settings will be restored to

the factory defaults.

OPE10

V/fPtm Setting

V/f Parameter Setting Error.

1. Check parameters E01.04 to E01.11.

OPE23

Load Check

Check C05.04 ≤ C05.07 ≤ C05.09.

1. Load check setting error.

OT1

Overtorque

Det 1

Overtorque Detection Level 1 Fault. Current is higher than set value (L06.02)

for more than set time (L06.03).

1. Check for proper programming of L06.02 and

L06.03.

OT2

Overtorque

Det 2

Overtorque Detection Level 2 Fault. Defined by L06.05. Alarm defined by L06.04.

1. Check for proper programming for L06.XX constant.

OV

DC Bus Overvolt

Overvoltage Fault. The DC bus voltage exceeds overvoltage level.

Detection level: 230V class - approximate 410V; 460V class - approximate 820V.

1. Extend the deceleration time.

2. Check for proper DBU operation.

3. Check the resistor.

4. Check the line voltage.

5. If on a load break hoist, check the gear box.

OV (flashing)

DC Bus Overvolt

Overvoltage Fault. Overvoltage occurs during stop. Main circuit DC voltage rises

above the detection level while the drive output is off. Detection level: 410V or

more for 230V; 820V or more for 460V.

1. Check the line voltage.

PF

Input Pha Loss

Input Phase Loss Fault. Inverter input power supply has open phase.

1. Check the line voltage.

2. Remove power.

3. Retighten the input terminal screws.

4. Check the fuses.

RR

DynBrk Transistr

Braking Transistor Fault. Internal Braking transistor failed.

1. Verify that the external braking resistor is

connected to the proper terminals.

2. Confirm that the proper resistor is installed.

3. Check for a short circuit across the braking resistor.

UL1

Upper Limt 1 Err

Upper Limit 1 - SLOW DOWN Indicator. Hoist has reached upper slow approach

limit. No action is required. Slow approach limits can be disabled by following the

instructions on page 19.

1. May not require corrective action.

2. Check the position of the limit switch.