S

ection

5— o

peration

16

Starting the Engine

WARNING!

This tractor is equipped with a safety

interlock system designed for the protection of the

operator. Do not operate the tractor if any part of the

system is malfunctioning. Periodically check the

function of the interlock system for proper operation.

WARNING!

For personal safety, the operator must

be sitting in the tractor seat when starting the

engine.

NOTE:

Refer to the Engine Operator’s Manual for oil fill-up

instructions and refer to the Assembly & Set-Up section for

gasoline fill-up instructions.

1.

Operator must be sitting in the tractor seat.

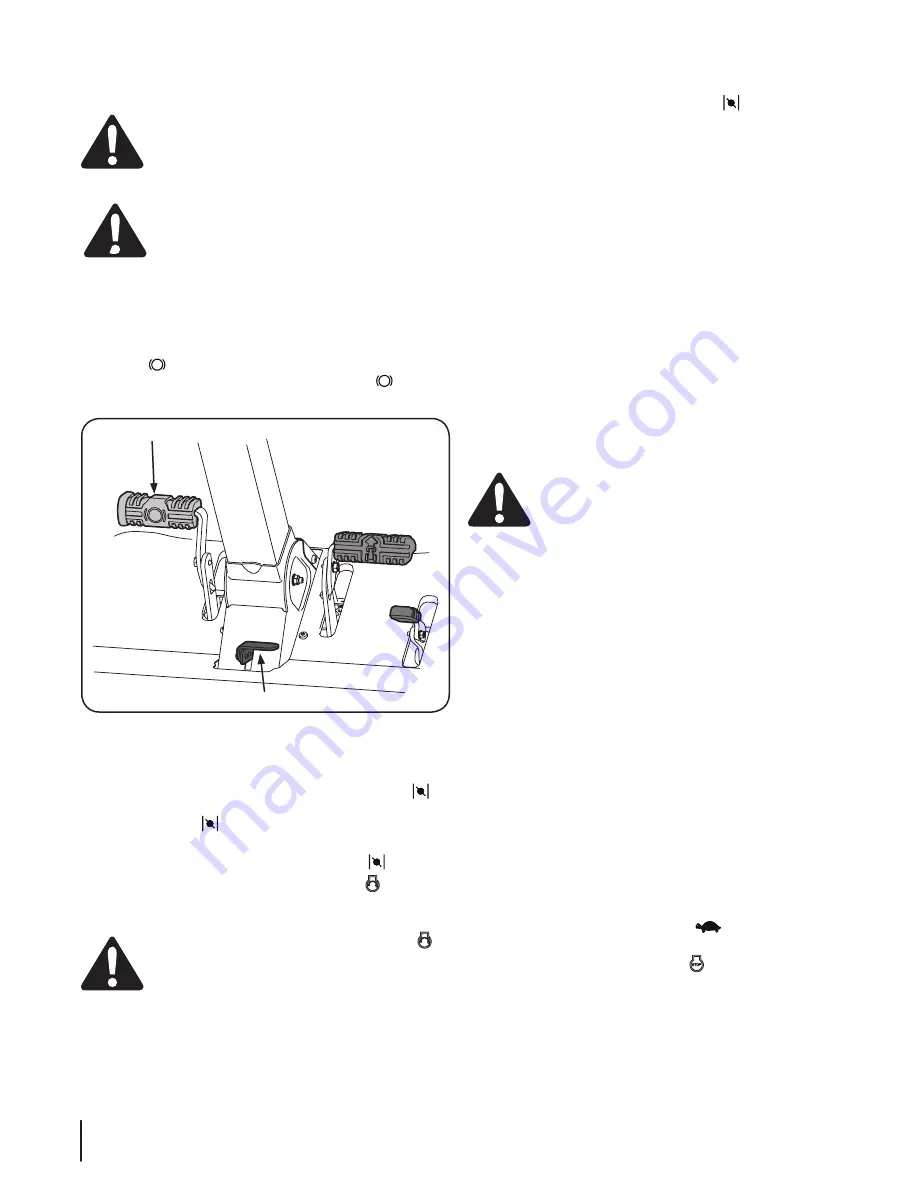

2.

Engage the parking brake by pressing forward on the brake

pedal

, then press down on the parking break/cruise

control lever and then release the brake pedal

. Refer to

Figure 5-1.

Brake Pedal

Parking Brake/Cruise Control Lever

Figure 5-1

3.

Make certain the PTO switch is in the disengaged (down)

position. Refer to Figure 5-1.

4.

Pull the choke knob (if equipped) up into the CHOKE

position or move the throttle/choke control (if equipped)

into the CHOKE position.

NOTE:

If the engine is warmed up, it may not be necessary to

place the throttle/choke control in the CHOKE position.

5.

Turn the ignition key clockwise to the START position.

After the engine starts, release the key. It will return to the

run position.

CAUTION:

Do NOT hold the key in the START

position for longer than ten seconds at a time. Doing

so may cause damage to your engine’s electric

starter.

6.

As the engine warms up, gradually pull the throttle/choke

control lever (if equipped) rearward past the choke detent

position or push the choke knob (if equipped) down into

the OFF position.

NOTE:

Do NOT leave the throttle/choke control (if equipped)

or the choke (if equipped) in the CHOKE position while

operating the tractor. Doing so will result in a “rich” fuel

mixture and cause the engine to run poorly.

7.

Allow the engine to run for a few minutes at mid throttle

before putting the engine under load.

8.

Observe the hour meter/indicator panel. If the battery indicator

light or oil pressure light come on, immediately stop the engine.

Have the tractor inspected by your Cub Cadet dealer.

Cold Weather Starting

When starting the engine at temperatures near or below freezing,

ensure the correct viscosity motor oil is used in the engine and the

battery is fully charged. Start the engine as follows:

1.

Be sure the battery is in good condition. A warm battery

has much more starting capacity than a cold battery.

2.

Use fresh winter grade fuel. Winter grade gasoline has

higher volatility to improve starting. Do not use gasoline

left over from summer.

3.

Follow the previous instruction for Starting the Engine.

Using Jumper Cables To Start Engine

WARNING!

Batteries contain sulfuric acid and

produce explosive gasses. Make certain the area is

well ventilated, wear gloves and eye protection, and

avoid sparks or flames near the battery.

If the battery charge is not sufficient to crank the engine,

recharge the battery. If a battery charger is unavailable and

the tractor must be started, the aid of a booster battery will be

necessary. Connect the booster battery as follows:

1.

Connect the end of one cable to the disabled tractor

battery’s positive terminal; then connect the other end of

that cable to the booster battery’s positive terminal.

2.

Connect one end of the other cable to the booster

battery’s negative terminal; then connect the other end of

that cable to the frame of the disabled tractor, as far from

the battery as possible.

3.

Start the disabled tractor following the normal starting

instructions previously provided; then disconnect the

jumper cables in the exact reverse order of their connection.

4.

Have the tractor’s electrical system checked and repaired

as soon as possible to eliminate the need for jump starting.

Stopping the Engine

1.

Place the PTO switch in the disengaged position.

2.

Engage the parking brake.

3.

Move the throttle/choke control (if equipped) or the

throttle (if equipped) to the SLOW

position and allow

the engine to idle for about one minute.

4.

Turn the ignition key to the STOP position and remove

the key from the ignition switch.

NOTE:

Always remove the key from the ignition switch to prevent

accidental starting or battery discharge if the equipment is left

unattended.

Содержание RZT S Series

Страница 38: ...Notes 38 ...