18

EC3-680-3 February 2017

Order # 5041558-0 & 5041679-0

5-7. CHAIN STOP INSTALLATION

Refer to Figures 8-6A. 6B and 6C, Chaining Parts, and proceed

as follows:

a. Disconnect slack end of chain from hoist.

b. Count (approx.) 12 links from slack end of chain and capture

the twelfth link with the two stop halves.

c. Install and tighten the two cap screws.

d. If no chain container is used, reattach the slack end of the chain

to the hoist. If a chain container is used, drop the slack end of

the chain into chain container.

e. Readjust "down" limit switch as necessary to give a

minimum clearance of 11/2" between chain stop end and

bottom of hoist.

This is a safety device only and is not intended to be a

substitute for the limit switch in the hoist.

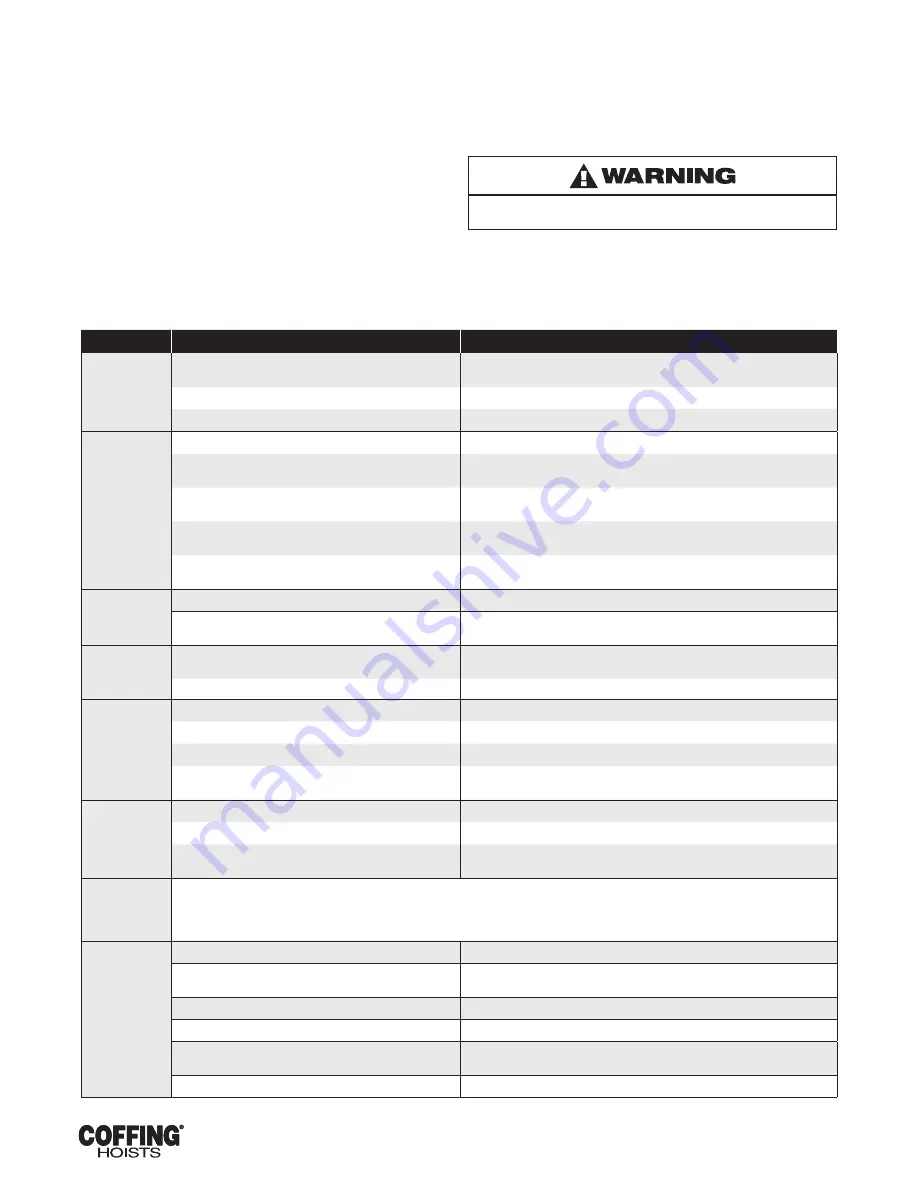

SECTION VI TROUBLESHOOTING

6-1. GENERAL

Use the following table as an aid to troubleshoot your hoist. If you do not have an experienced machinist-electrician to do your repair work,

we recommend that you send your hoist to an approved service center for repairs.

Problem

Probable Cause

Remedy

Hook Fails to

Stop at End of

Travel.

1. Limit switches not operating.

1. Check adjustment. See paragraph 5-2. Check connections against wiring

diagram. Tighten loose connections or replace.

2. Limit switch nuts not moving on shaft.

2. Check for stripped threads or bent nut guide.

3. Magnetic reversing switch malfunction.

3. Remove electrical cover and check reversing switch.

Hoist Does Not

Respond to

Pushbutton.

1. Power failure in supply lines.

1. Check circuit breakers, switches and connections in power supply lines.

2. Wrong voltage or frequency.

2. Check voltage and frequency of power supply against the rating on the

nameplate of the hoist.

3. Improper connections in hoist or pushbutton station.

3. Check all connections at line connectors and on terminal block.

Check terminal block on dual voltage hoists for proper voltage connections.

4. Motor brake does not release.

4. Check connections to the solenoid coil. Check for open or short circuit. Check

for proper adjustment. See paragraph 5-3.

5. Faulty magnetic hoist control switch.

5. Check coils for open or short circuit. Check all connections in control circuit.

Check for burned contacts. Replace as needed.

Hook Does Not

Stop Promptly.

1. Hoist overloaded.

1. Reduce load to within rated capacity of hoist.

2. Brake not holding.

2. Check motor brake adjustment (see paragraph 5-3) and load brake

(Figure 4-3).

Hook Moves in

Wrong Direction.

1. Three-phase reversal.

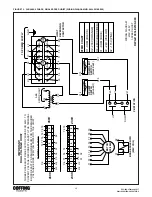

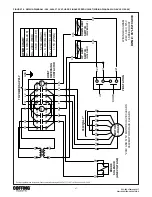

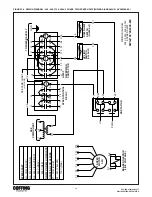

1. Reverse any two wires (except the green ground wire) at the power source (see

paragraph 2-3).

2. Improper connections.

2. Check all connections against Wiring Diagram.

Hoist Hesitates

to Lift When

Energized.

1. Hoist overloaded.

1. Reduce load to within rated capacity of hoist.

2. Motor brake requires adjustment.

2. Check motor brake adjustment. See Figure 5-2.

3. Worn overload limiting clutch.

3. Replace clutch.

4. Low voltage.

4. Check voltage at hoist power cord with hoist starting. Voltage should be no less

than 90% of voltage specified on hoist.

Hook Raises But

Will Not Lower.

(Motor not

running)

1. “Down” circuit open.

1. Check circuit for loose connections. Check “Down” limit switch for malfunction.

2. Broken conductor in pushbutton cable.

2. Check each conductor in the cable. If one is broken, replace entire cable.

3. Faulty magnetic hoist control switch.

3. Check coils for open or short circuit. Check all connections in control circuit.

Check for burned contacts. Replace as needed.

Hook Raises But

Will Not Lower

When Motor Is

Operating.

Consult Factory or Authorized Duff-Norton Warranty Repair Station.

Hook Lowers But

Will Not Raise.

1. Hoist overloaded.

1. Reduce load to within rated capacity.

2. Low voltage.

2. Determine cause of low voltage and bring up to at least 10% of the voltage

specified on hoist. Line voltage should be measured while holding or lifting load.

3. “UP” circuit open.

3. Check circuit for loose connections. Check “UP” limit switch for malfunction.

4. Broken conductor in pushbutton cable.

4. Check each conductor in the cable. If one is broken, replace entire cable.

5. Faulty magnetic hoist control switch.

5. Check coils for open or short circuit. Check all connections in control circuit.

Check for burned Contacts. Replace as needed.

6. Worn overload limiting clutch.

6. Replace clutch.