9

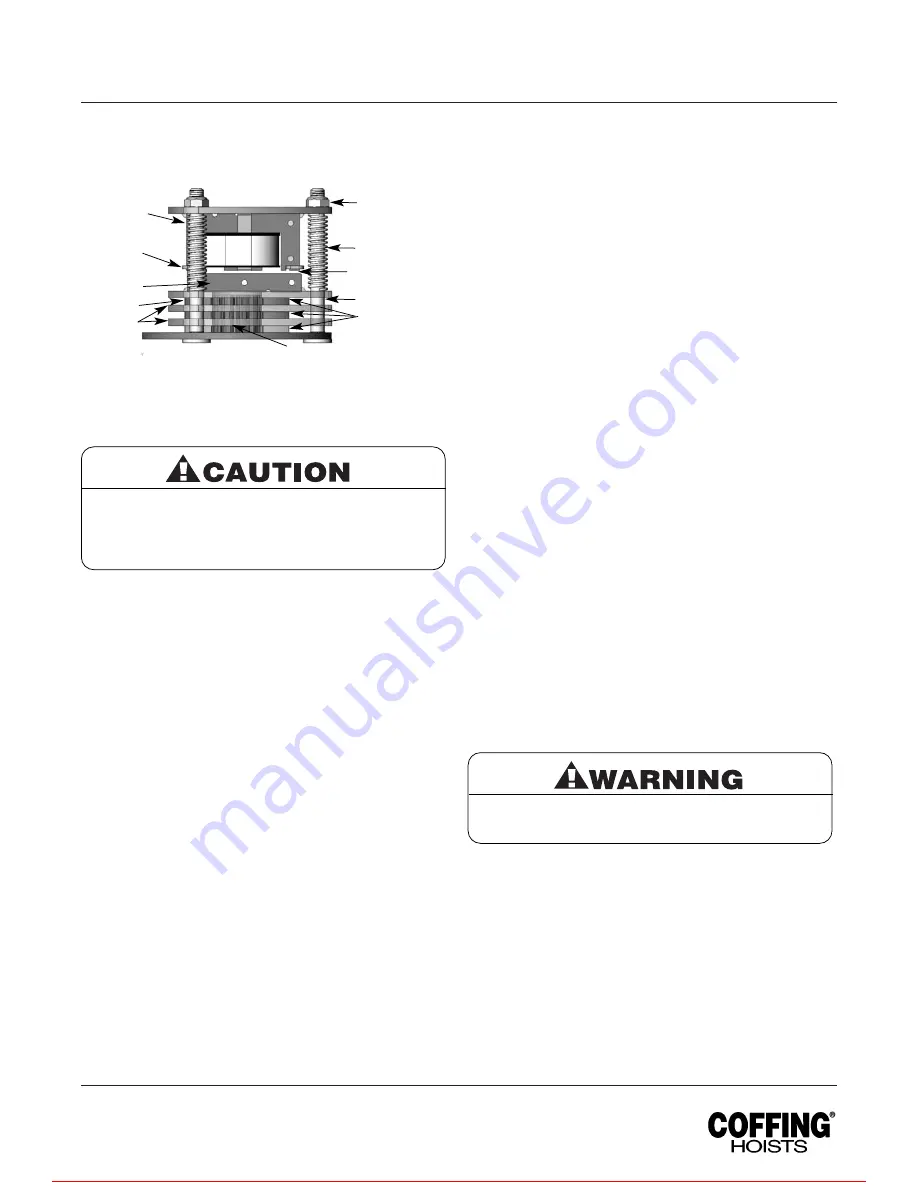

3. Adjust gap by adjusting the 3 locknuts “F” and checking with

a feeler gauge to be sure gap is the same on both ends of

the solenoid.

4. Adjustment is now complete and the brake properly set.

Replace the electrical cover, reconnect the power supply,

and check lifting motor brake action.

WIRING

Refer to Figures 7A, 7B and 7C.

Single-phase units (115/230V) are wired for 230V and

230/460V-3 phase units are wired for 230V unless otherwise

specified when ordering. Lifting motors ordered with other

3-phase voltages are single-voltage only. Conversion of dual

voltage units can be done simply and quickly as follows.

1. DISCONNECT LIFTING MOTOR FROM POWER SUPPLY

and remove electrical cover.

2. On 230/460V-3 phase units converting to 460V requires

removing the C1, C2 and C3 jumpers as shown on the

wiring diagram 983CE2100-000. The motor leads T4, T5 and

T6 are then connected to the blocks as shown. Save the

three jumper wires for conversions back to 230V. One of the

transformer leads H2 (230V) and H4 (460V) is connected to

the contactor as shown depending on the voltage.

On 115/230V-1 phase units, connections are only modified

at the terminal blocks as shown on wiring diagram

981CE0100-000.

3. Make sure that all of the screw clamps on the contactor and

terminal blocks are tightened. Tug on the wires to ensure

they are securely connected.

4. Check the operation of the lifting motor, ensuring that the

direction of travel is correct (See INSTALLING LIFTING

MOTOR, page 5).

IMPORTANT: Always refer to the wiring diagram located on the

inside of the electrical cover or Figures 7A, 7B and 7C when

performing electrical repairs. Make sure all terminals are securely

fastened and check for damaged insulation. It is also imperative

that the power circuit has conductors of adequate size.

LUBRICATION

Refer to Figure 9.

Proper lubrication is necessary to ensure a long and reliable

lifting motor life. Refer to the following and the

RECOMMENDED LUBRICATION SCHEDULE for lubrication

points, type of lubricant, and frequency of lubrication.

Load Chain

Clean the load chain with acid-free solvent and coat with new

SAE 90 gear oil. Wipe excess oil to prevent dripping. Never

apply grease to the chain.

Gearing

The gearbox of this lifting motor is filled at assembly with 1½

pints of SAE 90 EP gear oil. To check oil level, hang the unit by

the suspension hook (the unit and decals will be upside down)

and remove the oil level check plug. With the lifting motor

hanging level, the gear oil should be even with the hole.

Bearings

All bearings except hook and idler sheave bearings are

lubricated at the factory and should not require additional

lubrication. Noisy or worn bearings should be replaced.

Limit Switch Shaft

Remove any dirt accumulation and spray with a general

purpose lubricant.

Hook Bearing

Apply a few drops of new SAE 30 gear or motor oil around the

edge of the bearing.

Idler Sheave Bearing (Bushing)

Disassemble load block and apply a light coat of NLGI #2

grease, or equivalent, inside of bearing.

NOTE: If lifting motor is used in an atmosphere containing

abrasive dust, frequent cleaning and oiling may be necessary.

LIFTING MOTOR REPAIRS

NOTE: If you do not have an experienced mechanic to do your

repair work, we recommend that you send your lifting motor to

an approved service station for repairs. Use authorized repair

parts only.

1. For major repairs or when the lifting motor is to be sectioned

in the suspension area, it will be necessary to move the

lifting motor to a workbench or table.

2. For repairs which can be done by removing the electrical

cover only, the lifting motor need not be moved. Lowering the

lifting motor to a convenient working level is desirable.

The following repair instructions will help you in understanding

repair procedures, when related to the Replacement Parts List

starting on page 16. For clarity these are broken down into areas.

Be sure the bottom of the armature does not bear

against the splined adapter “H”. As adjustments are

made, the built-in clearance will be reduced. When

this clearance is gone REPLACE BRAKE DISCS.

Minimum allowable disc thickness is .162". See

Figure 13 for further illustration.

Remove load and disconnect lifting motor from

power supply before starting to do any repairs or to

take any sections apart.

Country Club Road

P.O. Box 779

Wadesboro, NC 28170 USA

TEL: (800) 477-5003

FAX: (800) 374-6853

Figure 4 — Brake Assembly

Gap

F

G

X

B

E

A

X

D

H

C

For more information contact: Sievert Crane and Hoist, (708) 771-1600, [email protected], www.sievertcrane.com