MODEL 520/525 INSTALLATION INSTRUCTIONS

Model 520/525 is a complete locking unit with all the parts necessary for a

new installation, or the total replacement of an existing lock.

IMPORTANT The mortice lock provided (fig. 2) has features which are not found in most other locks

and so it is recommended that you familiarise yourself with them as follows:

A. When necessary the hand

of the latchbolt can be

changed by removing the

three screws holding the

faceplate to the lockcase

and reversing the latchbolt.

B. Put the key in the cylinder

and insert it centrally into

the lockcase. Fix it in

position with the long bolt

through the faceplate. It

should now be possible to

project and retract the

deadbolt with the key, and

also to retract the latchbolt.

C. The square latchbolt

follower is in 2 parts: the

inside ‘panic function’

follower will retract the

latchbolt and also the

deadbolt when it is

projected. The effect of

this is to ensure that it is

not possible to accidentally

lock someone in a room

because the deadbolt is

projected. The outside

follower will always retract

the latchbolt whenever the

lever handle is depressed

after a correct code is

entered, but it will not

retract the deadbolt.

The hand of the ‘panic

function’ is determined as

follows: the grub screws

on the split follower facing

the code side must be

removed. This prevents

the outside handle

retracting the deadbolt.

NEVER remove grub

screws from both sides at

the same time.

All door locks should be

installed with a degree of

precision to ensure that all

components are horizontally

and vertically accurate in

relation to each other, and in

relation to the door.

Do not install the lock where

it will involve cutting into a

joint between the door stile

and a mid-rail.

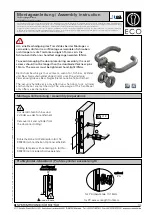

step 8

Fitting the strike plate.

NB: The plunger beside the

latchbolt deadlocks it to

protect against manipulation

or ‘shimming’. The strike plate

must be accurately installed

so that the plunger CANNOT

enter the aperture when the

door is closed, even if it is

slammed shut.

Position the strike plate on

the door frame so that it lines

up with the flat of the

latchbolt, and NOT the

plunger. Mark the positions of

the fixing screws, and draw

around the aperture of the

strike plate. Chisel out the

aperture 15mm deep to

receive the latchbolt. Fix the

strike plate to the surface of

the frame using only the top

fixing screw. Gently close the

door and check that the

latchbolt enters the aperture

easily, and is held without too

much ‘play’. When satisfied,

draw around the outline of the

strike plate, remove it and cut

a rebate to enable the

faceplate to lie flush with the

surface. Re-fix the strike plate

using both screws.

step 9

Apply the front and back

plates, with the neoprene

seals in position, against the

door, over the protruding

ends of the spindle.

step 10

Fix the two plates together

using the socket head bolts,

starting with the top fixing.

Ensure that the two plates

are truly vertical and then

tighten the bolts using the ‘T’

shaped Allen key. Do not use

excessive force.

step 11

Before closing the door,

enter the code and ensure

that the latchbolt will retract

when the lever handle is

depressed. Now check the

operation of the inside lever

handle. If there is any binding

of the handles or latch then

loosen the bolts slightly and

reposition the plates slightly

until the correct position is

found, and then re-tighten

the bolts.