AA

10

www.cmtorangetools.com

OPTIONAL CMT300-T064 TEMPLATE

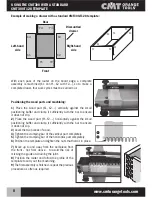

Example of making a drawer with a standard CMT300-T064 template:

Dismantled

drawer

Right-hand

side

Left-hand

side

Rear

Front

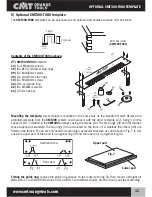

Y4

Y3

Y1

Y2

X4

X1

X3

X2

X3

X4

Y3

X2

X1

Y4

Y1

Y2

With each pass of the router, a complete assembly is machined on

the workpiece (X1 with Y1, X2 with Y2...), so to make a complete

drawer, four work cycles must be carried out.

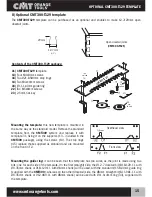

Positioning the wood parts and machining:

1)

Place the wood part (X1, X2....) vertically against the small

positioning buffer and clamp it sufficiently with the bar to ensure

it does not slip.

2)

Place the wood part (Y1, Y2....) horizontally against the small

positioning buffer and clamp it sufficiently with the bar to ensure

it does not slip.

3)

Level the two pieces of wood.

4)

Tighten the clamping bar of the vertical part completely.

5)

Tighten the clamping bar of the horizontal part completely.

6)

Position the template and tighten the nuts to hold it in place.

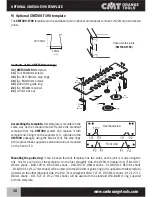

7)

Move up to and away from the workpiece from

the front - not from above - to avoid the risk of

missing the guide and ruining the joint.

8)

Position the router and follow the profile of the

template to carry out the machining.

9)

The first assembly is finished - repeat the

previous procedure as often as required.

Содержание CMT300

Страница 2: ......

Страница 113: ...113 NOTE www cmtorangetools com ...

Страница 114: ...114 NOTE www cmtorangetools com Note ...

Страница 115: ...115 NOTE www cmtorangetools com ...