M03Q40G6-03 30/07/08

pag

9

RESIDUAL RISKS

GENERAL

This section lists some of the more common situations

which, being beyond the control of the manufacturer, could

be a source of risk to persons or property.

DANGER AREA

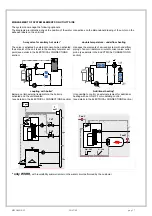

The figure below highlights the area in which only

authorised personnel may operate.

•

External danger zone

, identified by a precise area

around the unit and its vertical projection on the

ground in the case of hanging unit.

•

Internal danger zone

, identified by the area that can

be entered only after having intentionally removed the

protecting panels or parts of these.

A

B

C

D

A =

2000mm

B =

2000mm

C =

2000mm

D =

2000mm

HANDLING

If handling operations are undertaken without adopting all

the necessary safety procedures and exercising due care,

the unit can fall or topple, causing damage — possibly

extremely serious — to persons and/or property, and to the

unit itself.

Ensure the unit is handled and manoeuvred as directed on

the packing and in the present manual, and in accordance

with local regulations.

In the event of refrigerant gas escaping, refer to the “Safety

datasheet” for the particular refrigerant.

INSTALLATION

Incorrect installation of the unit can result in water leaks,

accumulation of condensate, escape of refrigerant, electric

shocks, fire, as well as irregular operation or damage to the

unit itself.

Make certain that the installation is carried out only by a

qualified technician, also that the directions contained in

this manual are followed and local statutory regulations

observed.

In the event of the unit being installed in a site where there

is even the slightest risk of inflammable gas escapes and

consequently the possibility of such gases accumulating in

area around the unit, the risk of explosion and fire cannot

be discounted.

Take every care and precaution when selecting the

installation site.

Installation on a structure not able to bear the weight and/or

afford a secure anchorage of the equipment may cause the

unit to fall and/or topple, resulting in damage to persons or

property, or to the unit itself. Make certain that every care

and precaution is taken when positioning and securing the

unit.

If the unit is easily accessible to children, unauthorized

persons or animals, this is a situation that can give rise

accidents and injuries, perhaps serious. Install the unit in a

place where access is allowed only to authorized persons,

or install barriers or guards preventing unauthorized entry.

GENERAL RISKS

A smell of burning, smoke or other indications of serious

irregularity could signal the onset of situations liable to

cause damage to persons or property or to the unit itself.

Isolate the unit from the electrical power supply (red-and-

yellow) switch.

Contact an authorized service centre so that the source of

the problem can be identified and remedied.

Accidental contact with heat exchange coils, compressors,

pressure pipelines or other components can result in

wounding or burns, or both.

Always wear suitable clothing, including protective gloves,

when working in the danger area.

Maintenance or repairs carried out by unskilled operatives

can result in harm or damage to persons and property, or to

the unit itself. Always contact an authorized service centre.

Failure to close the panels of the unit, or to check that all

the fixing screws of the panels are properly tightened, can

result in harm or damage to persons or property, or to the

unit itself.

Verify periodically that all panels are closed and made

properly secure.

In the event of fire, the temperature of the refrigerant can

rise to the point that pressure will exceed safety levels and

perhaps cause fluid to be projected. It may also happen

that parts of the circuit isolated by closed valves will

explode.

Do not stand near safety valves, and never leave the valves

of the refrigerant circuit closed.

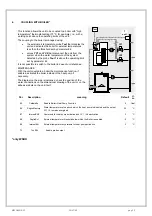

ELECTRICAL SYSTEM

If the power line connecting the unit to the a.c. supply is

incomplete, or if the connection is made with cables of

incorrect cross section and/or with insufficiently rated

protective devices, this can result in electric shock, toxicity

hazard, damage to the unit or fire.

All work on the electrical system should be carried out

referring to the wiring diagram and to the directions given in

this manual, and the system itself must be dedicated.

Failure to secure the cover enclosing electrical components

can lead to the infiltration of dust and water, ultimately

causing electric shocks, damage to the unit, or fire.

Always fasten the cover securely to the unit.

If live metal parts of the unit are not connected properly to

the earth system, they can cause electric shock or even

death by electrocution.

Make absolutely certain that the connection to the earth

system is made in accordance with correct practice.

Contact with live parts rendered accessible internally of the

unit when the guards are removed can result in electric

shock, burns or death by electrocution.

Before exposing these parts, make certain the isolating

switch on the power line to the unit is set to the OFF

position and padlocked, and post a warning sign.