Apex Tool Group

P2055MA | 2019-09

5

EN

1

About this document

The original language of this description is German.

This document provides important information on safe and

correct installation.

Secondary information

Symbols in the text

2

Safety

2.1 General Requirements

Only operate the system after reading and fully under-

standing this document. Failure to follow the directions

and safety instructions could result in electric shocks,

burns and/or serious injuries.

Keep this document in a safe place for future refer-

ence! Provide this documentation to the designer,

installer and commissioning personnel of the machine

or equipment on which this product is used.

Read and observe all applicable, universal and local

safety and accident regulations. These safety state-

ments do not raise any right to completeness

2.2 Intended Use

The owner is responsible for using the machine according

to its designated use. The fastening system may be used

only under the following conditions:

•

The Spindle is designed for stationary operation only

and is intended exclusively for fastening and loosening

thread connections. Do not use as a hand-held tool.

•

Use the Spindle only in combination with these

controller from Cleco Production Tools.

-

mPro400SG-CPM(…)

•

The Spindle must be fully assembled. Insert and lock

all connecting cables.

•

Only cable types and accessory parts approved by

Apex Tool Group may be used.

•

Unauthorized alterations, repairs and modifications are

prohibited.

•

A repair is only permitted by Apex Tool Group autho-

rized personnel. If repair is required, send the com-

plete component to

Sales & Service Centers

.

•

Always remove the complete Spindle from a unit.

2.3 Predictable Misuse

Do not use the Spindle:

•

In potentially explosive areas.

•

In damp locations or outdoors.

•

In non-industrial applications (eg residential area).

2.4 Operator Training

•

The fastening system may only be put into operation,

adjusted, tested, maintained and serviced by quali-

fied

1)

and trained personnel.

•

Personnel must be instructed by qualified employees

of Apex Tool Group.

•

The operator must make sure that all new operating

and maintenance personnel are instructed in the oper-

ation and maintenance of the fastening system to the

same extent and with the same care and attention.

•

Personnel who are being trained may work on the fas-

tening system only under the supervision of an experi-

enced operator.

Order no.

Sort

P1713E

System handbook Fixtured Spindle

P2090WA

Service Manual

P2102JH

Installation Instructions

Cable Management

P3223H

Declaration of Incorporation for Incomplete

Machines

italic

Menu options (e.g.,

Diagnostics)

input

fields, check boxes, radio buttons or drop-

down menus.

>

Indicates selection of a menu option from

a menu, e.g.,

File

>

<…>

Specifies switches, pushbuttons or the

keys of an external keyboard, e.g., <F5>

Courier

Filenames and paths, e.g.,

setup.exe

•

List

-

List, level 2

a)

b)

Options

→

Result

1. (...)

2. (...)

Action steps

Single action step

Sales &

Service

Centers

Cleco Production Tools Sales & Service

Center, see last page.

Spindle

Stands for all versions of the

Intelligent

Spindle

described here.

1

Due to their training, knowledge, experience and understand-

ing of the circumstances involved in this kind of work, suitably qual-

ified personnel are able to identify potential hazards and to initiate

appropriate safety measures. Qualified personnel are obliged to

comply with regulations.

Содержание BB P2055MA

Страница 4: ...4 P2055MA 2019 09 Apex Tool Group EN ...

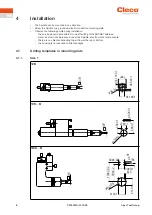

Страница 9: ...Apex Tool Group P2055MA 2019 09 9 EN 4 1 2 Size 2 2ZB 2VK B 2WK B 0 ...

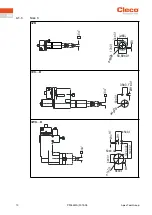

Страница 10: ...10 P2055MA 2019 09 Apex Tool Group EN 4 1 3 Size 3 3ZB 3VK B 3WK B 0 ...

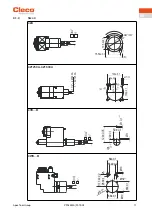

Страница 11: ...Apex Tool Group P2055MA 2019 09 11 EN 4 1 4 Size 4 4ZA 4Z1250A 4Z1600A 4VK B 4WK B 0 ...

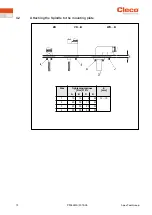

Страница 15: ......