Apex Tool Group

P2055MA | 2019-09

13

EN

5

Initial operation

1. Position the Spindle components together via flat

toothed interfaces, see Service manual.

-

Turn size 1 in 15° increments.

-

Turn sizes 4 to 2 in 10° increments.

2. Connect all components.

3. Establish a grounding connection on the mounting

plate to ensure the function.

4. However, protective earthing of moving parts has to be

made acc. to EN 60204-1.

5. Close all plug connectors and lock.

The red ring around the outer diameter of plug connec-

tors with a slide lock should not be visible.

6. Connect the mains cable to the controller.

7. Preset the ARCNET address on each Tightening Mod-

ule STM(…)

via BCD-code switch

:

-

Upper switch for tens digit (

0

0-

9

0)

-

Bottom switch for ones digit (0

0

-0

9

)

-

Admissible settings 01 to 32.

-

The address adjustment can be checked upon

power-up or reset at the two-digit 7-segment dis-

play.

8. Close the protective devices (e.g. safety grilles).

9. Switch on the machine control unit (PLC/SPS).

10. Switch on the controller.

11. If there are no faults pending after switching on the

unit, the "Ready" LED on the tightening module lights

up green. Otherwise see System Handbook for Trou-

ble Shooting.

12. Enter the parameters for the torque / angle setting via

the controller.

The controller is programmed prior to initial operation

by Apex Tool Group. When switching on the controller

for the first time, the parameters for controlling the fas-

tening sequences must be read in via the keyboard or

via a valid parameter file. Process programming of the

controller see Programming Manual.

Danger

High leakage current –

Fatal electric shock could occur.

Establish a grounding connection (PE)

to the controller before taking into op-

eration!

Caution

Risk of tripping or falling over.

Loose cables on the ground.

Lay all connected cables safely.

•

Always switch off the controller before

making adjustments.

•

Each address can be used only once

in the system. Otherwise an error is

triggered on the controller.

Содержание BB P2055MA

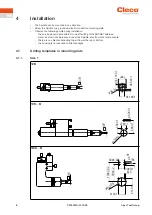

Страница 4: ...4 P2055MA 2019 09 Apex Tool Group EN ...

Страница 9: ...Apex Tool Group P2055MA 2019 09 9 EN 4 1 2 Size 2 2ZB 2VK B 2WK B 0 ...

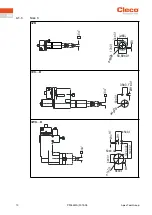

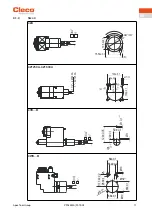

Страница 10: ...10 P2055MA 2019 09 Apex Tool Group EN 4 1 3 Size 3 3ZB 3VK B 3WK B 0 ...

Страница 11: ...Apex Tool Group P2055MA 2019 09 11 EN 4 1 4 Size 4 4ZA 4Z1250A 4Z1600A 4VK B 4WK B 0 ...

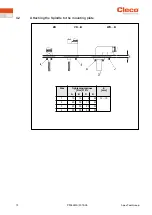

Страница 15: ......