Page 18

PL12EN-48ET

02/15/2013

Cleco

®

Maintenance

8

Maintenance

---------------------------------------------------------------------------------------------------------------------------------------

Danger of injury from accidental start up or electrical shock.

Disconnect the tool cable from the tool and controller before performing any maintenance.

---------------------------------------------------------------------------------------------------------------------------------------

8.1

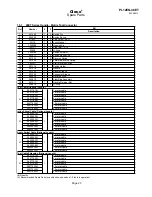

Service schedule

Only qualified and trained personnel are permitted to perform maintenance on these tools.

Regular maintenance reduces operating faults, repair costs and downtime. In addition to the following

service schedule, implement a safety related maintenance program that takes the local regulations for

repair and maintenance for all operating phases of the tool into account.

This maintenance schedule uses values that are valid for most applications. For a specific maintenance

interval, refer to 8.1.1 Calculating a customer-specific maintenance plan.

Maintenance

Interval

Rundowns

Daily

Daily

Ú

Ú

Ú

Ú

Visual inspection of all cables and connections

Visual inspection of the 48ET tool

Check the tool for excessive vibration or unusual noises

Visual inspection of all external components of the tool

W1

100,000

Ú

Ú

Ú

Ú

Inspect the tool cable for damage or wear

inspect the square drive output spindle for damage or wear

Inspect the tool cable connection for a secure fit

Check the maximum free speed

W2

500,000

Ú

Ú

Ú

Ú

Visual inspection of disassembled 48ET tool

Check individual parts for wear or damage and replace if necessary

Clean and lubricate angle head, gearing and motor bearings

Check and recalibrate transducer (48ET models)

W3

1,000,000

Ú

Ú

Ú

Ú

Visual inspection of disassembled 48ET tool

Check individual parts for wear or damage and replace if necessary

Clean and lubricate angle head, gearing and motor bearings

Check and recalibrate transducer (48ET models)

Designation