6. TROUBLESHOOTING

GENERAL

The following may cause failure of the power unit:

- Inadequate electrical power (Voltage or Amperage), verify that the electrical power supplied

complies with the power unit’s requirement.

- Abnormal performances of the electronic control module or the motor.

Before calling a service technician, in case of a malfunction, please review the following situations by

running the following simple diagnostics:

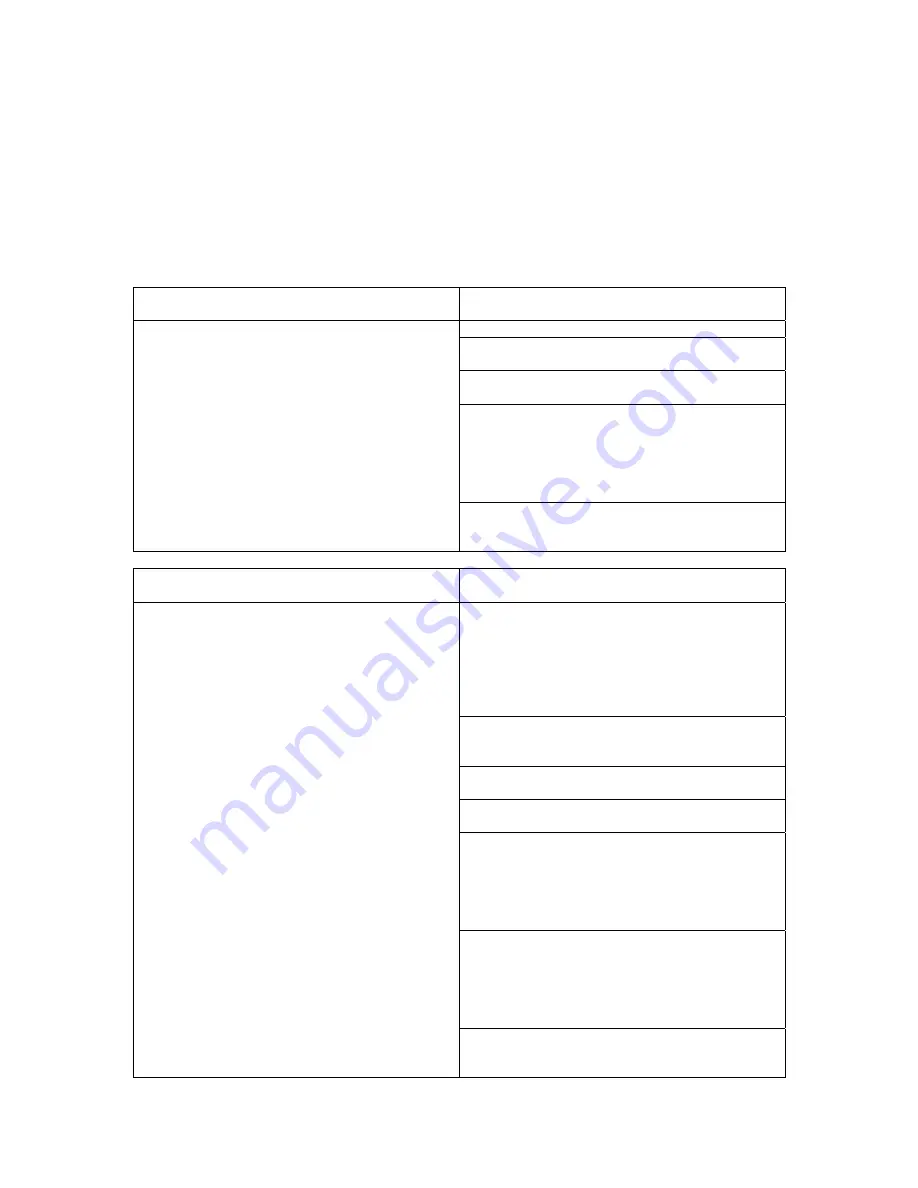

SITUATION

VERIFICATION

THE POWER UNIT DOES NOT

OPERATE

Verify that there is power in the electrical outlet.

Verify the breaker or the fuse in the electrical

panel.

Verify that the power cord is adequately plugged

into the electrical outlet.

Verify that all low voltage connections are

adequate at every valve location. Open every

valve, one at a time, and make contact between

the two small pins with a metal object. If all the

valves work properly, take a look at the low

voltage circuit or switch on the hose.

If the power unit still does not work after the

above diagnostic, bring the unit to the nearest

authorized service centre or agent.

SITUATION

VERIFICATION

LOW OR NO SUCTION OR AIR FLOW AT ALL

Verify the cleaning tool or the hose for possible

obstruction. If the hose is obstructed, try to

“massage” the clog out. Try to “reverse” the hose

by inserting the cleaning end of the hose in the

wall valve and making contact with the two (2)

small metal contact pins, hold your hand around

the opening for air tightness.

Verify if the disposable bag is full, if so replace

disposable bag and/or that the filter may be

clogged, if so clean the permanent filter.

Verify if the debris canister is adequately placed

on the unit with no air leaks.

Verify that all other valves are shut and that there

is no air leaks.

If one of the vacuum valves has noticeably less

power than the others, it is a sign of a clog at this

particular valve. Write a different number on a

few paper tissues and pick one up in every valve

in the home; see in the debris canister which one

is missing so to find which valve is obstructed.

If none of the valves function properly and the

power unit is running; unhook the flexible pipe on

the top of the power unit from the debris intake

line. If you have plenty of power there, it is a sign

that the clog is between the last valve and the

power unit.

If the power unit still does not work after the

above diagnostic, bring the unit to the nearest

authorized service centre or agent.