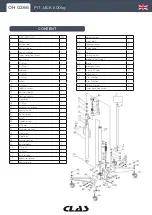

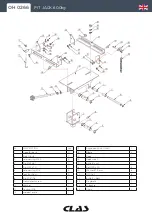

OH 0266

PIT JACK 600kg

MAINTENANCE

USE

ATTENTION !

Avant la première utilisation,

veuillez remplacer le bouchon

de transport en place par l’écrou

de mise à l’air libre joint

à cette étiquette.

Une fois l’écrou serré, desserrer

la vis à l’interieur de l’écrou

d’1 à 2 tours pour effectuer

la mise à l’air.

Ne pas la resserrer ensuite.

CAUTION!

Before first use, please

replace the transport plug

in place with the vent nut

included with this label.

Once the nut is tightened,

loosen the screw inside the

nut by 1 to 2 turns to vent.

Do not tighten it again

afterwards.

WARNING! Before use ensure you have read, understood

and apply safety instructions.

WARNING! Ensure you prepare vehicle correctly before

attempting to use the Transmission Jack.

POSITIONING JACK BENEATH LOAD.

Before use ensure the transmission weight and size does

not exceed the capacity of the jack.

LOWERING THE LOAD.

WARNING! Ensue the load is central and stable on the

jack saddle and load is fi xed in place

before attempting to lift, lower, or transport.

SLOWLY turn the release valve knob anti-clockwise to

GENTLY lower saddle to the lowest minimum height

before attempting to transport load.

Ensure the jack’s descent is slow and controlled to avoid the risk of sudden dropping which could

be dangerous. The valve will automatically return to the closed position when the knob is released.

TRANSPORTING THE LOAD.

WARNING! Ensure you have read, understood and apply safety instructions.

IMPORTANT: Only fully qualifi ed personnel should attempt maintenance or repair.

When the jack is not in use, the saddle must be in the lowest position

Keep the jack clean and wipe off any oil or grease. Lubricate all moving parts with acid free oil.

The oil cylinder is a sealed unit and must not be accessed. For service contact your authorised

dealer.

WARNING! Only a good quality Jack oil must be used, DO NOT use brake fl uid.

Before each use, follow the pre-check list to ensure components are in good working order.

DO NOT use the jack if you believe it has been subjected to an abnormal load or shock.

Periodically check the pump piston and piston rod for signs of corrosion. Clean exposed areas

with a clean oiled cloth.

Содержание OH 0266

Страница 1: ...clas com VERIN DE FOSSE 600kg PIT JACK 600kg OH 0266...

Страница 11: ...OH 0266 PIT JACK 600kg...