6

Parts & Service: 020 8988 7400 / E-mail: [email protected] or [email protected]

MAINTENANCE

1. Before using the airline, drain water from the air reservoir at the compressor.

2. Check any supply airline filter for blockage and clean if necessary.

3. Check the condition and the filter

bowl and clean out as follows if

badly contaminated.

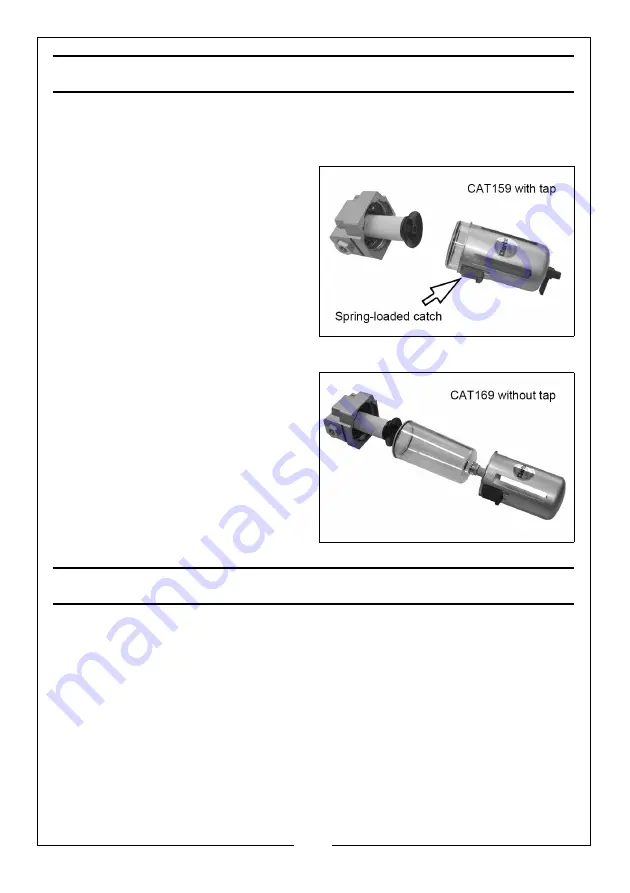

4. Remove the outer bowl cover by

pulling the spring loaded catch

down and twisting the bowl

45deg, then pulling the bowl from

the body (against any frictional

resistance from the O-ring).

NOTE:

In the case of the CAT159 the

bowl and bowl cover will remain connected by the drain tap.

5. The clear bowl and filter element

can then be washed out before

re-assembly.

GUARANTEE

This product is guaranteed against faulty manufacture for a period of 12

months from the date of purchase. Please keep your receipt which will be

required as proof of purchase.

This guarantee is invalid if the product is found to have been abused or

tampered with in any way, or not used for the purpose for which it was

intended.

Faulty goods should be returned to their place of purchase, no product can

be returned to us without prior permission.

This guarantee does not effect your statutory rights.

Содержание Air CAT159

Страница 8: ......