8

Parts & Service: 020 8988 7400 / E-mail: [email protected] or [email protected]

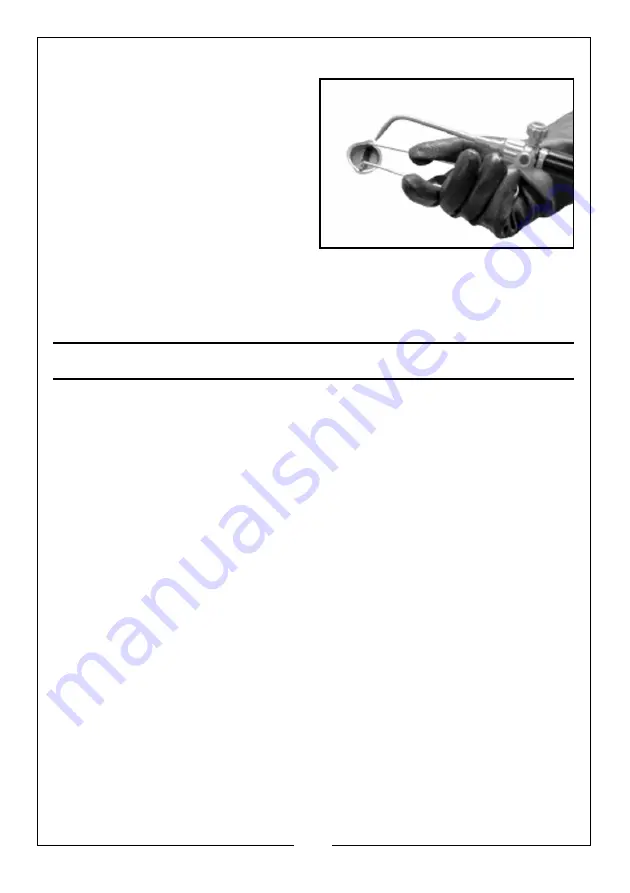

LIGHTING THE TORCH (FIG 9)

Open the torch acetylene valve

approximately one half turn and

ignite using the supplied spark igniter.

Open the torch valve until the flame

stops excessive smoking and leaves

the end of the nozzle tip about 3mm,

then reduce slightly to bring the

flame back to the tip.

Open the torch oxygen valve until a

bright inner cone appears in the

flame.

The point at which the feathery edges of the flame disappear and a sharp

inner cone is visible is called the “Neutral Flame”.

BASIC WELDING PROCEDURES

Gas welding is a method of joining similar metals by heating the adjacent

surfaces to melting point with an oxyacetylene flame and allowing the two

parts to fuse together with a filler metal being required on materials 5mm thick

or more. The resulting weld is as strong as the parent metal.

All metal to be joined should be thoroughly cleaned before welding. Oil,

grease, rust, scale or other impurities affect the weld quality and the tensile

strength. Metal of 5mm and over should be bevelled before attempting to

weld and when bevelled edges are to be joined. A filler rod of the same

material must be used.

The table below is a guide only showing recommended, oxygen and

acetylene pressures relating to the size of the material to be welded etc.

If a too larger tip is used and the flame is softened, the tip heats up

unnecessarily and is often accompanied by a popping noise which splatters

the weld puddle. Too hot a flame burns the steel and too small a flame is not

big enough to get the job done.

WELDING ROD

Welding rods are available in various sizes with the most common being

1.6mm, 2.4mm and 3.2mm. They are also available for welding mild steel, cast

iron and aluminium.

The size of rod will be determined by the type of weld, the metal thickness and

the amount of filler metal required.