FOREWORD

Instruction manual covers Imo Pump Series A3D pumps. Series of pumps have been designed to meet

requirements for hydraulic, distillate, lubricating, residual and crude oil applications. Because of large

number of operating conditions, it is necessary to have a variety of construction and material combinations

to meet job requirements. Model of each pump is identified on pump nameplate. Correct use of manual

requires identification of Figure(s) applicable to pump assembly and seal arrangement. Refer to Table 1,

assembly drawings, Figures 3, 7, 8, 9, 10 and mechanical seal drawings, Figure 2, for applicable pump seal

selection. Packing pumps are illustrated in Figures 4, 5, 6. If pump type is not specifically identifiable in

manual, contact Imo Service Department with pump model and serial number for assistance 704-289-6511.

Instructions given herein cover generally the operation and maintenance of subject equipment.

Should any questions arise which may not be answered specifically by these instructions, they

should be referred to Imo Pump for further detailed information and technical assistance.

Manual cannot possibly cover every situation connected with operation, adjustment, test, overhaul and

maintenance of equipment furnished. Every effort is made to prepare text of manual so that engineering

and design data is transformed into most easily understood wording. Imo Pump, in furnishing this

equipment and this manual, must presume that operating and maintenance personnel assigned thereto

have sufficient technical knowledge and experience to apply sound safety and operational practices which

may not be otherwise covered herein.

In applications where Imo Pump furnished equipment is to be integrated with a process or other machinery,

these instructions should be thoroughly reviewed to determine proper integration of equipment into overall

plant operational procedures. On critical or dangerous equipment, provide suitable safety and emergency

systems to protect personnel and property from injury due to pump malfunction. If pump handles

flammable, toxic, corrosive or explosive fluids, provide for safety in event of pump leakage or malfunction.

If installation, operation, and maintenance instructions are not correctly and strictly followed and observed,

serious damage to pump could result. Imo Pump cannot accept responsibility for unsatisfactory

performance or damage resulting from failure to comply with instructions.

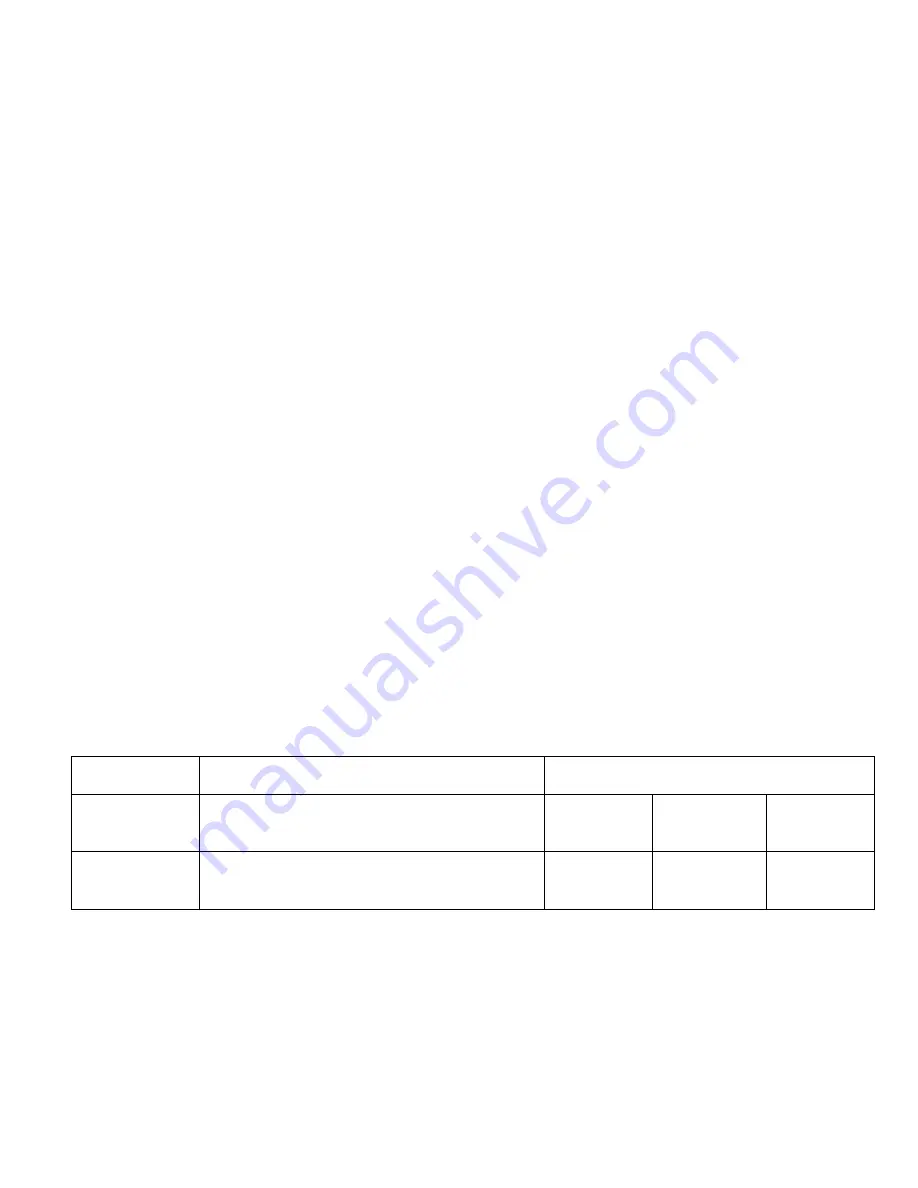

Table 1

SERIES A3D TYPICAL PUMP ASSEMBLY DRAWINGS

MECHANICAL

SEALS

PACKING

PUMPS

Rotor Size

106, 118, 137, 156, 187, 218, 250, 275, 337,

312, 350, 400

106,118

137,156,187

218,250,275

Figure No.

3, 7, 8, 9, 10

4

5

6

Figure 1 - Definitions of Model Designators