OPERATING MANUAL

MIG (GMAW) WELDING

5-32

Manual 0-5586

Basic GMAW (MIG) Welding Troubleshooting

FAULT

CAUSE

REMEDY

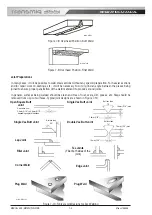

1 Undercut

A Welding arc voltage too

high.

A Decrease voltage or increase the wire feed speed.

B Incorrect torch angle

B Adjust angle.

C Excessive heat input

C Increase the torch travel speed and/or decrease

welding current by decreasing the voltage or

decreasing the wire feed speed.

2 Lack of penetration A Welding current too low A Increase welding current by increasing wire feed

speed and increasing voltage.

B Joint preparation too

narrow or gap too tight

B Increase joint angle or gap.

C Shielding gas incorrect C Change to a gas which gives higher penetration.

3 Lack of fusion

Voltage too low

Increase voltage.

4 Excessive spatter

A Voltage too high

A Decrease voltage or increase the wirespeed control.

B Voltage too low

B Increase the voltage or decrease wirespeed.

5 Irregular weld shape A Incorrect voltage

and current settings.

Convex, voltage too low.

Concave, voltage too

high.

A Adjust voltage and current by adjusting the voltage

control and the wirespeed control.

B Wire is wandering.

B Replace contact tip.

C Incorrect shielding gas

C Check shielding gas.

D Insufficient or excessive

heat input

D Adjust the wirespeed control or the voltage control.

6 Weld cracking

A Weld beads too small

A Decrease travel speed

B Weld penetration narrow

and deep

B Reduce current and voltage and increase Mig torch

travel speed or select a lower penetration shielding

gas.

C Excessive weld stresses C Increase weld metal strength or revise design

D Excessive voltage

D Decrease voltage.

E Cooling rate too fast

E Slow the cooling rate by preheating part to be

welded or cool slowly.

7 Cold weld puddle

A Loose welding cable

connection.

A Check all welding cable connections.

B Low primary voltage

B Contact supply authority.

C Fault in power source

C Have an Accredited CIGWELD Service Provider to

test then replace the faulty component.

8 Arc does not have

a crisp sound that

short arc exhibits

when the wirefeed

speed and voltage

are adjusted

correctly.

The MIG torch has been

connected to the wrong

voltage polarity on the

front panel.

Connect the MIG torch to the positive (+) welding

terminal for solid wires and gas shielded flux cored

wires. Refer to the electrode wire manufacturer for

the correct polarity.

Table 5-4: GMAW (MIG) Welding Problems

Содержание Transmig 355i

Страница 8: ...This Page Intentionally Blank ...

Страница 14: ...OPERATING MANUAL GENERAL INFORMATION 1 6 Manual 0 5586 This Page Intentionally Blank ...

Страница 24: ...OPERATING MANUAL INTRODUCTION 2 10 Manual 0 5586 This Page Intentionally Blank ...

Страница 28: ...OPERATING MANUAL INSTALLATION 3 4 Manual 0 5586 This Page Intentionally Blank ...

Страница 84: ...OPERATING MANUAL TIG GTAW WELDING 6 10 Manual 0 5586 This Page Intentionally Blank ...

Страница 110: ...OPERATING MANUAL KEY SPARE PARTS 9 4 Manual 0 5586 This page intentionally blank ...

Страница 112: ...OPERATING MANUAL APPENDIX A 2 Manual 0 5550 This Page Intentionally Blank ...

Страница 115: ...OPERATING MANUAL Transmig 220i This Page Intentionally Blank ...