CAUTION: Some clutch packs appear similar, but

they are not the same. Do not interchange clutch

components, as they might fail.

HYDRAULICS

The hydraulics of the transaxle provide:

•

Manual shift lever select function

•

Main line pressure regulation

•

Torque converter and cooler flow control

Oil flow to the friction elements is controlled

directly by four solenoid valves. The hydraulics also

include a unique logic- controlled solenoid torque con-

verter clutch control valve. This valve locks out the

1st gear reaction element with the application of 2nd,

direct, or overdrive gear elements. It also redirects

the 1st gear solenoid output so that it can control

torque converter clutch operation. To regain access to

1st gear, a sequence of commands must be used to

move the solenoid TCC control valve. This precludes

any application of the 1st gear reaction element with

other elements applied. It also allows one solenoid to

control two friction elements.

Small, high-rate accumulators are provided in each

controlled friction element circuit. These serve to

absorb the pressure responses, and allow the controls

to read and respond to changes that are occurring.

SOLENOIDS

The solenoid valves perform most control functions,

these valves must be extremely durable and tolerant

of dirt. For that reason hardened-steel poppet and

ball valves are used. These are free from any close

operating clearances. The solenoids operate the

valves directly without any intermediate element.

Direct operation means that these units must have

very high output. They must close against the size-

able flow areas and high line pressures. Fast

response is also required to meet the control require-

ments.

Two of the solenoids are normally-venting and two

are normally-applying; this was done to provide a

default mode of operation. With no electrical power,

the transmission provides 2nd gear in (OD), (3), or

(L) shift lever positions. All other transmission lever

positions will operate normally. The choice of 2nd

gear was made to provide adequate breakaway per-

formance while still accommodating highway speeds.

SENSORS

There are three pressure switches to identify sole-

noid application. There are two speed sensors to read

input (torque converter turbine) and output (parking

sprag) speeds. There is also a transmission range

sensor to indicate the manual shift lever position.

The pressure switches are incorporated in an assem-

bly with the solenoids. Engine speed, throttle posi-

tion, temperature, etc., are also observed. Some of

these signals are read directly from the engine con-

trol sensors; others are read from a multiplex circuit

with the powertrain control module.

ELECTRONICS

The 41TE Transmission Control Module (TCM) is

located underhood in a potted, die-cast aluminum

housing. The module used is a new controller called

EATX III. The TCM has a sealed, 60-way connector.

ADAPTIVE CONTROLS

These controls function by reading the input and

output speeds over 140 times a second and respond-

ing to each new reading. This provides the precise

and sophisticated friction element control needed to

make smooth clutch-to-clutch shifts for all gear

changes. The use of overrunning clutches or other

shift quality aids are not required. As with most

automatic transaxles, all shifts involve releasing one

element and applying a different element. In simpli-

fied terms, the upshift logic allows the releasing ele-

ment to slip backwards slightly. This ensures that it

does not have excess capacity. The apply element is

filled until it begins to make the speed change to the

higher gear. The apply pressure is then controlled to

maintain the desired rate of speed change. This con-

tinues until the shift is made. The key to providing

excellent shift quality is precision. For example, the

release element for upshifts is allowed to slip back-

wards slightly. The amount of that slip is typically

less than a total of 20 degrees. To achieve that pre-

cision, the TCM learns the traits of the transaxle

that it is controlling. It learns the release rate of the

releasing element and the apply time of the applying

element. It also learns the rate at which the apply

element builds pressure sufficient to begin making

the speed change. This method achieves more preci-

sion than would be possible with exacting tolerances.

It can also adapt to any changes that occur with age

or environment.

For kickdown shifts, the control logic allows the

releasing element to slip. Then controls the rate at

which the input (and engine) accelerate. When the

lower gear speed is achieved, the releasing element

reapplies to maintain that speed until the apply ele-

ment is filled. This provides quick response since the

engine begins to accelerate immediately. This also

provides a smooth torque exchange since the release

element can control the rate of torque increase. This

control can make any powertrain feel more respon-

sive without increasing harshness.

Adaptive controls respond to input speed changes.

They compensate for changes in engine or friction

element torque and provide good, consistent shift

quality for the life of the transaxle.

NS

TRANSAXLE AND POWER TRANSFER UNIT

21 - 73

DESCRIPTION AND OPERATION (Continued)

Содержание 1998 Voyager

Страница 8: ...FASTENER IDENTIFICATION NS INTRODUCTION 5 GENERAL INFORMATION Continued ...

Страница 9: ...FASTENER STRENGTH 6 INTRODUCTION NS GENERAL INFORMATION Continued ...

Страница 11: ...METRIC CONVERSION 8 INTRODUCTION NS GENERAL INFORMATION Continued ...

Страница 12: ...TORQUE SPECIFICATIONS NS INTRODUCTION 9 GENERAL INFORMATION Continued ...

Страница 16: ......

Страница 26: ......

Страница 93: ...RED BRAKE WARNING LAMP FUNCTION NS BRAKES 5 11 DIAGNOSIS AND TESTING Continued ...

Страница 94: ...POWER BRAKE SYSTEM DIAGNOSTICS 5 12 BRAKES NS DIAGNOSIS AND TESTING Continued ...

Страница 95: ...VEHICLE ROAD TEST BRAKE NOISE NS BRAKES 5 13 DIAGNOSIS AND TESTING Continued ...

Страница 222: ...COOLING SYSTEM DIAGNOSIS 7 8 COOLING SYSTEM NS DIAGNOSIS AND TESTING Continued ...

Страница 223: ...NS COOLING SYSTEM 7 9 DIAGNOSIS AND TESTING Continued ...

Страница 224: ...7 10 COOLING SYSTEM NS DIAGNOSIS AND TESTING Continued ...

Страница 225: ...NS COOLING SYSTEM 7 11 DIAGNOSIS AND TESTING Continued ...

Страница 226: ...7 12 COOLING SYSTEM NS DIAGNOSIS AND TESTING Continued ...

Страница 280: ......

Страница 286: ......

Страница 289: ...CHARGING SYSTEM SCHEMATIC TYPICAL NS CHARGING SYSTEM 8C 3 DIAGNOSIS AND TESTING Continued ...

Страница 291: ...CHARGING SYSTEM TEST NS CHARGING SYSTEM 8C 5 DIAGNOSIS AND TESTING Continued ...

Страница 292: ...OVERCHARGE TEST 8C 6 CHARGING SYSTEM NS DIAGNOSIS AND TESTING Continued ...

Страница 294: ...VOLTAGE DROP TEST 8C 8 CHARGING SYSTEM NS ...

Страница 298: ......

Страница 372: ......

Страница 377: ...NS GS INSTRUMENT PANEL AND SYSTEMS 8E 5 DIAGNOSIS AND TESTING Continued ...

Страница 378: ...8E 6 INSTRUMENT PANEL AND SYSTEMS NS GS DIAGNOSIS AND TESTING Continued ...

Страница 379: ...NS GS INSTRUMENT PANEL AND SYSTEMS 8E 7 DIAGNOSIS AND TESTING Continued ...

Страница 380: ...8E 8 INSTRUMENT PANEL AND SYSTEMS NS GS DIAGNOSIS AND TESTING Continued ...

Страница 381: ...NS GS INSTRUMENT PANEL AND SYSTEMS 8E 9 DIAGNOSIS AND TESTING Continued ...

Страница 382: ...8E 10 INSTRUMENT PANEL AND SYSTEMS NS GS DIAGNOSIS AND TESTING Continued ...

Страница 383: ...NS GS INSTRUMENT PANEL AND SYSTEMS 8E 11 DIAGNOSIS AND TESTING Continued ...

Страница 384: ...8E 12 INSTRUMENT PANEL AND SYSTEMS NS GS DIAGNOSIS AND TESTING Continued ...

Страница 385: ...NS GS INSTRUMENT PANEL AND SYSTEMS 8E 13 DIAGNOSIS AND TESTING Continued ...

Страница 386: ...8E 14 INSTRUMENT PANEL AND SYSTEMS NS GS DIAGNOSIS AND TESTING Continued ...

Страница 402: ......

Страница 421: ...Fig 2 Speed Control Circuit NS VEHICLE SPEED CONTROL SYSTEM 8H 5 DIAGNOSIS AND TESTING Continued ...

Страница 428: ......

Страница 440: ......

Страница 478: ......

Страница 496: ......

Страница 504: ......

Страница 508: ......

Страница 524: ......

Страница 530: ...Fig 1 Seat Motor Test Fig 2 Power Seat Switch Test 8R 2 POWER SEATS NS DIAGNOSIS AND TESTING Continued ...

Страница 540: ...Fig 1 Power Mirror Test Fig 2 Mirror Switch Test 8T 2 POWER MIRRORS NS DIAGNOSIS AND TESTING Continued ...

Страница 542: ......

Страница 546: ......

Страница 550: ......

Страница 559: ...SPECIAL TOOLS SPECIAL TOOL Degausser 6029 NS OVERHEAD CONSOLE 8V 9 ...

Страница 560: ......

Страница 562: ......

Страница 564: ...8W 01 2 8W 01 GENERAL INFORMATION NS GS DESCRIPTION AND OPERATION Continued ...

Страница 565: ...NS GS 8W 01 GENERAL INFORMATION 8W 01 3 DESCRIPTION AND OPERATION Continued ...

Страница 568: ...Wiring Diagram Symbols 8W 01 6 8W 01 GENERAL INFORMATION NS GS DESCRIPTION AND OPERATION Continued ...

Страница 580: ......

Страница 616: ......

Страница 660: ......

Страница 664: ......

Страница 704: ......

Страница 718: ......

Страница 728: ......

Страница 740: ......

Страница 744: ......

Страница 758: ......

Страница 768: ......

Страница 784: ......

Страница 792: ......

Страница 796: ......

Страница 800: ......

Страница 814: ......

Страница 822: ......

Страница 826: ......

Страница 832: ......

Страница 836: ......

Страница 840: ......

Страница 876: ......

Страница 972: ...Fig 1 Ground Locations LHD 8W 90 8 8W 90 CONNECTOR GROUND LOCATIONS NS GS DESCRIPTION AND OPERATION Continued ...

Страница 976: ...Fig 5 Engine Connections 2 0L LHD 8W 90 12 8W 90 CONNECTOR GROUND LOCATIONS NS GS DESCRIPTION AND OPERATION Continued ...

Страница 979: ...Fig 8 Engine Connections 2 5L LHD NS GS 8W 90 CONNECTOR GROUND LOCATIONS 8W 90 15 DESCRIPTION AND OPERATION Continued ...

Страница 984: ...Fig 13 Cowl Panel Connections LHD 8W 90 20 8W 90 CONNECTOR GROUND LOCATIONS NS GS DESCRIPTION AND OPERATION Continued ...

Страница 985: ...Fig 14 Body Connections LHD NS GS 8W 90 CONNECTOR GROUND LOCATIONS 8W 90 21 DESCRIPTION AND OPERATION Continued ...

Страница 986: ...Fig 15 HVAC Connections LHD 8W 90 22 8W 90 CONNECTOR GROUND LOCATIONS NS GS DESCRIPTION AND OPERATION Continued ...

Страница 987: ...Fig 16 Body Connections LHD NS GS 8W 90 CONNECTOR GROUND LOCATIONS 8W 90 23 DESCRIPTION AND OPERATION Continued ...

Страница 988: ...Fig 17 Roof Panel Connections LHD 8W 90 24 8W 90 CONNECTOR GROUND LOCATIONS NS GS DESCRIPTION AND OPERATION Continued ...

Страница 989: ...Fig 18 Body to Door Connections LHD NS GS 8W 90 CONNECTOR GROUND LOCATIONS 8W 90 25 DESCRIPTION AND OPERATION Continued ...

Страница 990: ...Fig 19 Door Connections LHD 8W 90 26 8W 90 CONNECTOR GROUND LOCATIONS NS GS DESCRIPTION AND OPERATION Continued ...

Страница 991: ...Fig 20 Underbody Connections LHD NS GS 8W 90 CONNECTOR GROUND LOCATIONS 8W 90 27 DESCRIPTION AND OPERATION Continued ...

Страница 994: ...Fig 23 Liftgate Connections LHD 8W 90 30 8W 90 CONNECTOR GROUND LOCATIONS NS GS DESCRIPTION AND OPERATION Continued ...

Страница 1001: ...Fig 1 Ground Locations RHD NS GS 8W 90 CONNECTOR GROUND LOCATIONS 8W 90 37 DESCRIPTION AND OPERATION Continued ...

Страница 1002: ...Fig 2 Engine Compartment Connetions RHD 8W 90 38 8W 90 CONNECTOR GROUND LOCATIONS NS GS DESCRIPTION AND OPERATION Continued ...

Страница 1003: ...Fig 3 Engine Compartment Connections RHD NS GS 8W 90 CONNECTOR GROUND LOCATIONS 8W 90 39 DESCRIPTION AND OPERATION Continued ...

Страница 1004: ...Fig 4 Engine Compartment Connections RHD 8W 90 40 8W 90 CONNECTOR GROUND LOCATIONS NS GS DESCRIPTION AND OPERATION Continued ...

Страница 1005: ...Fig 5 Engine Connections 2 0L RHD NS GS 8W 90 CONNECTOR GROUND LOCATIONS 8W 90 41 DESCRIPTION AND OPERATION Continued ...

Страница 1006: ...Fig 6 Engine Connections 2 4L M T RHD 8W 90 42 8W 90 CONNECTOR GROUND LOCATIONS NS GS DESCRIPTION AND OPERATION Continued ...

Страница 1007: ...Fig 7 Engine Connections 2 4L A T RHD NS GS 8W 90 CONNECTOR GROUND LOCATIONS 8W 90 43 DESCRIPTION AND OPERATION Continued ...

Страница 1008: ...Fig 8 Engine Connections 2 5L RHD 8W 90 44 8W 90 CONNECTOR GROUND LOCATIONS NS GS DESCRIPTION AND OPERATION Continued ...

Страница 1009: ...Fig 9 Engine Connections 3 3L 3 8L RHD NS GS 8W 90 CONNECTOR GROUND LOCATIONS 8W 90 45 DESCRIPTION AND OPERATION Continued ...

Страница 1010: ...Fig 10 Instrument Panel Connections RHD 8W 90 46 8W 90 CONNECTOR GROUND LOCATIONS NS GS DESCRIPTION AND OPERATION Continued ...

Страница 1011: ...Fig 11 Instrument Panel Connections RHD NS GS 8W 90 CONNECTOR GROUND LOCATIONS 8W 90 47 DESCRIPTION AND OPERATION Continued ...

Страница 1012: ...Fig 12 Instrument Panel Connections RHD 8W 90 48 8W 90 CONNECTOR GROUND LOCATIONS NS GS DESCRIPTION AND OPERATION Continued ...

Страница 1013: ...Fig 13 Cowl Panel Connections RHD NS GS 8W 90 CONNECTOR GROUND LOCATIONS 8W 90 49 DESCRIPTION AND OPERATION Continued ...

Страница 1014: ...Fig 14 Body Connections RHD 8W 90 50 8W 90 CONNECTOR GROUND LOCATIONS NS GS DESCRIPTION AND OPERATION Continued ...

Страница 1015: ...Fig 15 HVAC Connections RHD NS GS 8W 90 CONNECTOR GROUND LOCATIONS 8W 90 51 DESCRIPTION AND OPERATION Continued ...

Страница 1016: ...Fig 16 Body Connections RHD 8W 90 52 8W 90 CONNECTOR GROUND LOCATIONS NS GS DESCRIPTION AND OPERATION Continued ...

Страница 1017: ...Fig 17 Roof Panel Connections RHD NS GS 8W 90 CONNECTOR GROUND LOCATIONS 8W 90 53 DESCRIPTION AND OPERATION Continued ...

Страница 1018: ...Fig 18 Body to Door Connections RHD 8W 90 54 8W 90 CONNECTOR GROUND LOCATIONS NS GS DESCRIPTION AND OPERATION Continued ...

Страница 1019: ...Fig 19 Door Connections RHD NS GS 8W 90 CONNECTOR GROUND LOCATIONS 8W 90 55 DESCRIPTION AND OPERATION Continued ...

Страница 1020: ...Fig 20 Underbody Connections RHD 8W 90 56 8W 90 CONNECTOR GROUND LOCATIONS NS GS DESCRIPTION AND OPERATION Continued ...

Страница 1021: ...Fig 21 Left Rear Quarter Connections RHD NS GS 8W 90 CONNECTOR GROUND LOCATIONS 8W 90 57 DESCRIPTION AND OPERATION Continued ...

Страница 1022: ...Fig 22 Right Rear Quarter Connections RHD 8W 90 58 8W 90 CONNECTOR GROUND LOCATIONS NS GS DESCRIPTION AND OPERATION Continued ...

Страница 1023: ...Fig 23 Liftgate Connections RHD NS GS 8W 90 CONNECTOR GROUND LOCATIONS 8W 90 59 DESCRIPTION AND OPERATION Continued ...

Страница 1024: ......

Страница 1027: ...Fig 1 Front End Splices LHD NS GS 8W 95 SPLICE LOCATIONS 8W 95 3 DESCRIPTION AND OPERATION Continued ...

Страница 1028: ...Fig 2 Engine Splices 2 0L LHD 8W 95 4 8W 95 SPLICE LOCATIONS NS GS DESCRIPTION AND OPERATION Continued ...

Страница 1029: ...Fig 3 Engine Splices 2 0L LHD NS GS 8W 95 SPLICE LOCATIONS 8W 95 5 DESCRIPTION AND OPERATION Continued ...

Страница 1030: ...Fig 4 Engine Splices 2 4L LHD 8W 95 6 8W 95 SPLICE LOCATIONS NS GS DESCRIPTION AND OPERATION Continued ...

Страница 1031: ...Fig 5 Engine Splices 2 5L LHD NS GS 8W 95 SPLICE LOCATIONS 8W 95 7 DESCRIPTION AND OPERATION Continued ...

Страница 1032: ...Fig 6 Engine Splices 3 3L 3 8L LHD 8W 95 8 8W 95 SPLICE LOCATIONS NS GS DESCRIPTION AND OPERATION Continued ...

Страница 1033: ...Fig 7 Engine Compartment Splices 3 3L 3 8L LHD NS GS 8W 95 SPLICE LOCATIONS 8W 95 9 DESCRIPTION AND OPERATION Continued ...

Страница 1034: ...Fig 8 Instrument Panel Splices LHD 8W 95 10 8W 95 SPLICE LOCATIONS NS GS DESCRIPTION AND OPERATION Continued ...

Страница 1035: ...Fig 9 Cowl Panel Splices LHD NS GS 8W 95 SPLICE LOCATIONS 8W 95 11 DESCRIPTION AND OPERATION Continued ...

Страница 1036: ...Fig 10 Left Door Splice LHD 8W 95 12 8W 95 SPLICE LOCATIONS NS GS DESCRIPTION AND OPERATION Continued ...

Страница 1037: ...Fig 11 Dome Harness Splices LHD NS GS 8W 95 SPLICE LOCATIONS 8W 95 13 DESCRIPTION AND OPERATION Continued ...

Страница 1038: ...Fig 12 Floor Pan and Underbody Splices LHD 8W 95 14 8W 95 SPLICE LOCATIONS NS GS DESCRIPTION AND OPERATION Continued ...

Страница 1040: ...Fig 1 Front End Splices RHD 8W 95 16 8W 95 SPLICE LOCATIONS NS GS DESCRIPTION AND OPERATION Continued ...

Страница 1041: ...Fig 2 Engine Splices 2 0L RHD NS GS 8W 95 SPLICE LOCATIONS 8W 95 17 DESCRIPTION AND OPERATION Continued ...

Страница 1042: ...Fig 3 Engine Splices 2 0L RHD 8W 95 18 8W 95 SPLICE LOCATIONS NS GS DESCRIPTION AND OPERATION Continued ...

Страница 1043: ...Fig 4 Engine Splices 2 4L RHD NS GS 8W 95 SPLICE LOCATIONS 8W 95 19 DESCRIPTION AND OPERATION Continued ...

Страница 1044: ...Fig 5 Engine Splices 3 3L 3 8L RHD 8W 95 20 8W 95 SPLICE LOCATIONS NS GS DESCRIPTION AND OPERATION Continued ...

Страница 1045: ...Fig 6 Engine Compartment Splices 3 3L 3 8L RHD NS GS 8W 95 SPLICE LOCATIONS 8W 95 21 DESCRIPTION AND OPERATION Continued ...

Страница 1046: ...Fig 7 Instrument Panel Splices RHD 8W 95 22 8W 95 SPLICE LOCATIONS NS GS DESCRIPTION AND OPERATION Continued ...

Страница 1047: ...Fig 8 Cowl Panel Splices RHD NS GS 8W 95 SPLICE LOCATIONS 8W 95 23 DESCRIPTION AND OPERATION Continued ...

Страница 1048: ...Fig 9 Left Door Splice RHD 8W 95 24 8W 95 SPLICE LOCATIONS NS GS DESCRIPTION AND OPERATION Continued ...

Страница 1049: ...Fig 10 Dome Harness Splices RHD NS GS 8W 95 SPLICE LOCATIONS 8W 95 25 DESCRIPTION AND OPERATION Continued ...

Страница 1050: ...Fig 11 Floor Pan and Underbody Splices RHD 8W 95 26 8W 95 SPLICE LOCATIONS NS GS DESCRIPTION AND OPERATION Continued ...

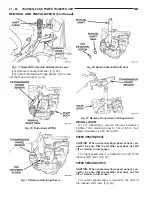

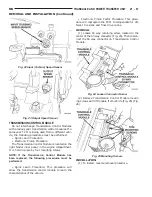

Страница 1077: ...Fig 27 Positioning Engine Cradle Support Post Mounts Typical NS 2 4L ENGINE 9 27 REMOVAL AND INSTALLATION Continued ...

Страница 1220: ...Fig 3 Lubrication Lines 9 42 ENGINE NS GS DESCRIPTION AND OPERATION Continued ...

Страница 1224: ...ENGINE DIAGNOSIS MECHANICAL CONT 9 46 ENGINE NS GS DIAGNOSIS AND TESTING Continued ...

Страница 1286: ...Fig 5 Front Crossmember Dimensions 13 6 FRAME AND BUMPERS NS SPECIFICATIONS Continued ...

Страница 1287: ...Fig 6 Engine Compartment Top View NS FRAME AND BUMPERS 13 7 SPECIFICATIONS Continued ...

Страница 1288: ...Fig 7 Engine Compartment and Frame Rail Side View 13 8 FRAME AND BUMPERS NS SPECIFICATIONS Continued ...

Страница 1289: ...Fig 8 Full Vehicle Bottom View NS FRAME AND BUMPERS 13 9 SPECIFICATIONS Continued ...

Страница 1290: ...Fig 9 Windshield Opening Fig 10 Liftgate Opening 13 10 FRAME AND BUMPERS NS SPECIFICATIONS Continued ...

Страница 1291: ...Fig 11 Body Side Openings NS FRAME AND BUMPERS 13 11 SPECIFICATIONS Continued ...

Страница 1292: ......

Страница 1302: ...FUEL PRESSURE BELOW SPECIFICATIONS 14 8 FUEL SYSTEM NS DIAGNOSIS AND TESTING Continued ...

Страница 1304: ...FUEL INJECTOR DIAGNOSIS 14 10 FUEL SYSTEM NS DIAGNOSIS AND TESTING Continued ...

Страница 1368: ......

Страница 1425: ...TORQUE CHART 2 5L DIESEL NS GS FUEL SYSTEM 2 5L DIESEL ENGINE 2 0L GAS ENGINE 14 57 SPECIFICATIONS Continued ...

Страница 1426: ......

Страница 1451: ...SPECIAL TOOLS POWER STEERING PUMP Installer C 4063B Puller C 4333 P S System Analyzer 6815 NS STEERING 19 25 ...

Страница 1463: ...Steering Column And Steering System Components NS STEERING 19 37 DESCRIPTION AND OPERATION Continued ...

Страница 1472: ......

Страница 1479: ...Diagnosis Guide NS TRANSAXLE AND POWER TRANSFER UNIT 21 5 DIAGNOSIS AND TESTING Continued ...

Страница 1480: ...Diagnosis Guide 21 6 TRANSAXLE AND POWER TRANSFER UNIT NS DIAGNOSIS AND TESTING Continued ...

Страница 1481: ...Diagnosis Guide NS TRANSAXLE AND POWER TRANSFER UNIT 21 7 DIAGNOSIS AND TESTING Continued ...

Страница 1482: ...Diagnosis Guide 21 8 TRANSAXLE AND POWER TRANSFER UNIT NS DIAGNOSIS AND TESTING Continued ...

Страница 1483: ...Diagnosis Guide NS TRANSAXLE AND POWER TRANSFER UNIT 21 9 DIAGNOSIS AND TESTING Continued ...

Страница 1484: ...Diagnosis Guide 21 10 TRANSAXLE AND POWER TRANSFER UNIT NS DIAGNOSIS AND TESTING Continued ...

Страница 1485: ...Diagnosis Guide NS TRANSAXLE AND POWER TRANSFER UNIT 21 11 DIAGNOSIS AND TESTING Continued ...

Страница 1486: ...Diagnosis Guide 21 12 TRANSAXLE AND POWER TRANSFER UNIT NS DIAGNOSIS AND TESTING Continued ...

Страница 1531: ...31TH TRANSAXLE HYDRAULIC SCHEMATIC NS TRANSAXLE AND POWER TRANSFER UNIT 21 57 SCHEMATICS AND DIAGRAMS Continued ...

Страница 1532: ...31TH TRANSAXLE HYDRAULIC SCHEMATIC 21 58 TRANSAXLE AND POWER TRANSFER UNIT NS SCHEMATICS AND DIAGRAMS Continued ...

Страница 1533: ...31TH TRANSAXLE HYDRAULIC SCHEMATIC NS TRANSAXLE AND POWER TRANSFER UNIT 21 59 SCHEMATICS AND DIAGRAMS Continued ...

Страница 1534: ...31TH TRANSAXLE HYDRAULIC SCHEMATIC 21 60 TRANSAXLE AND POWER TRANSFER UNIT NS SCHEMATICS AND DIAGRAMS Continued ...

Страница 1535: ...31TH TRANSAXLE HYDRAULIC SCHEMATIC NS TRANSAXLE AND POWER TRANSFER UNIT 21 61 SCHEMATICS AND DIAGRAMS Continued ...

Страница 1536: ...31TH TRANSAXLE HYDRAULIC SCHEMATIC 21 62 TRANSAXLE AND POWER TRANSFER UNIT NS SCHEMATICS AND DIAGRAMS Continued ...

Страница 1537: ...31TH TRANSAXLE HYDRAULIC SCHEMATIC NS TRANSAXLE AND POWER TRANSFER UNIT 21 63 SCHEMATICS AND DIAGRAMS Continued ...

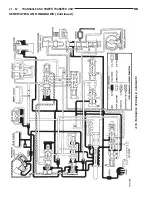

Страница 1620: ...41TE TRANSAXLE HYDRAULIC SCHEMATIC 21 146 TRANSAXLE AND POWER TRANSFER UNIT NS SCHEMATICS AND DIAGRAMS Continued ...

Страница 1621: ...41TE TRANSAXLE HYDRAULIC SCHEMATIC NS TRANSAXLE AND POWER TRANSFER UNIT 21 147 SCHEMATICS AND DIAGRAMS Continued ...

Страница 1622: ...41TE TRANSAXLE HYDRAULIC SCHEMATIC 21 148 TRANSAXLE AND POWER TRANSFER UNIT NS SCHEMATICS AND DIAGRAMS Continued ...

Страница 1623: ...41TE TRANSAXLE HYDRAULIC SCHEMATIC NS TRANSAXLE AND POWER TRANSFER UNIT 21 149 SCHEMATICS AND DIAGRAMS Continued ...

Страница 1624: ...41TE TRANSAXLE HYDRAULIC SCHEMATIC 21 150 TRANSAXLE AND POWER TRANSFER UNIT NS SCHEMATICS AND DIAGRAMS Continued ...

Страница 1625: ...41TE TRANSAXLE HYDRAULIC SCHEMATIC NS TRANSAXLE AND POWER TRANSFER UNIT 21 151 SCHEMATICS AND DIAGRAMS Continued ...

Страница 1626: ...41TE TRANSAXLE HYDRAULIC SCHEMATIC 21 152 TRANSAXLE AND POWER TRANSFER UNIT NS SCHEMATICS AND DIAGRAMS Continued ...

Страница 1627: ...41TE TRANSAXLE HYDRAULIC SCHEMATIC NS TRANSAXLE AND POWER TRANSFER UNIT 21 153 SCHEMATICS AND DIAGRAMS Continued ...

Страница 1628: ...41TE TRANSAXLE HYDRAULIC SCHEMATIC 21 154 TRANSAXLE AND POWER TRANSFER UNIT NS SCHEMATICS AND DIAGRAMS Continued ...

Страница 1629: ...41TE TRANSAXLE HYDRAULIC SCHEMATIC NS TRANSAXLE AND POWER TRANSFER UNIT 21 155 SCHEMATICS AND DIAGRAMS Continued ...

Страница 1630: ...41TE TRANSAXLE HYDRAULIC SCHEMATIC 21 156 TRANSAXLE AND POWER TRANSFER UNIT NS SCHEMATICS AND DIAGRAMS Continued ...

Страница 1631: ...41TE TRANSAXLE HYDRAULIC SCHEMATIC NS TRANSAXLE AND POWER TRANSFER UNIT 21 157 SCHEMATICS AND DIAGRAMS Continued ...

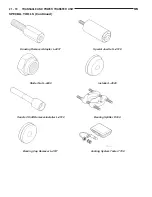

Страница 1638: ...Installer 6536 A Cooler Flusher 6906A Puller 7794 A 21 164 TRANSAXLE AND POWER TRANSFER UNIT NS SPECIAL TOOLS Continued ...

Страница 1640: ...Power Transfer Unit Components 21 166 TRANSAXLE AND POWER TRANSFER UNIT NS DIAGNOSIS AND TESTING Continued ...

Страница 1656: ......

Страница 1723: ...LEAD CORRECTION CHART NS TIRES AND WHEELS 22 5 DIAGNOSIS AND TESTING Continued ...

Страница 1726: ...SPECIFICATIONS TIRE SPECIFICATIONS 22 8 TIRES AND WHEELS NS ...

Страница 1807: ...Fig 130 Body Side Moldings Highline Fig 131 Body Side Moldings Premium NS BODY 23 77 REMOVAL AND INSTALLATION Continued ...

Страница 1830: ...Blower Motor Noise Vibration Diagnosis 24 14 HEATING AND AIR CONDITIONING NS DIAGNOSIS AND TESTING Continued ...

Страница 1866: ......

Страница 1879: ...Blower Motor Noise Vibration Diagnosis NS GS HEATING AND AIR CONDITIONING 24 13 DIAGNOSIS AND TESTING Continued ...

Страница 1904: ......

Страница 1928: ......