SKU 46507

PAGE 7

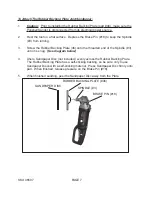

To Attach The Rubber Backing Plate And Sandpaper:

1.

Caution: Prior to installing the Rubber Backing Plate (part #46), make sure the

Polisher/Sander is disconnected from its electrical power source.

2.

Rest the tool on a flat surface. Depress the Brake Pin (#18) to keep the Spindle

(#3) from turning.

3.

Screw the Rubber Backing Plate (46) onto the threaded end of the Spindle (#3)

until it is snug. (See diagram below)

4.

Ahere Sandpaper Disc (not included) evenly across the Rubber Backing Plate.

The Rubber Backing Plate has a self-sticking backing, so be sure only to use

Sandpaper Discs with a self-sticking material. Press Sandpaper Disc firmly onto

pad. When finished, release pressure on the Brake Pin (#18).

5.

When finished sanding, peel the Sandpaper Disc away from the Plate.

BRAKE PIN (#18)

RUBBER BACKING PLATE (#46)

SPINDLE (#3)

SANDPAPER DISC