Page 12

For technical questions, please call 1-800-444-3353.

SKU 93213

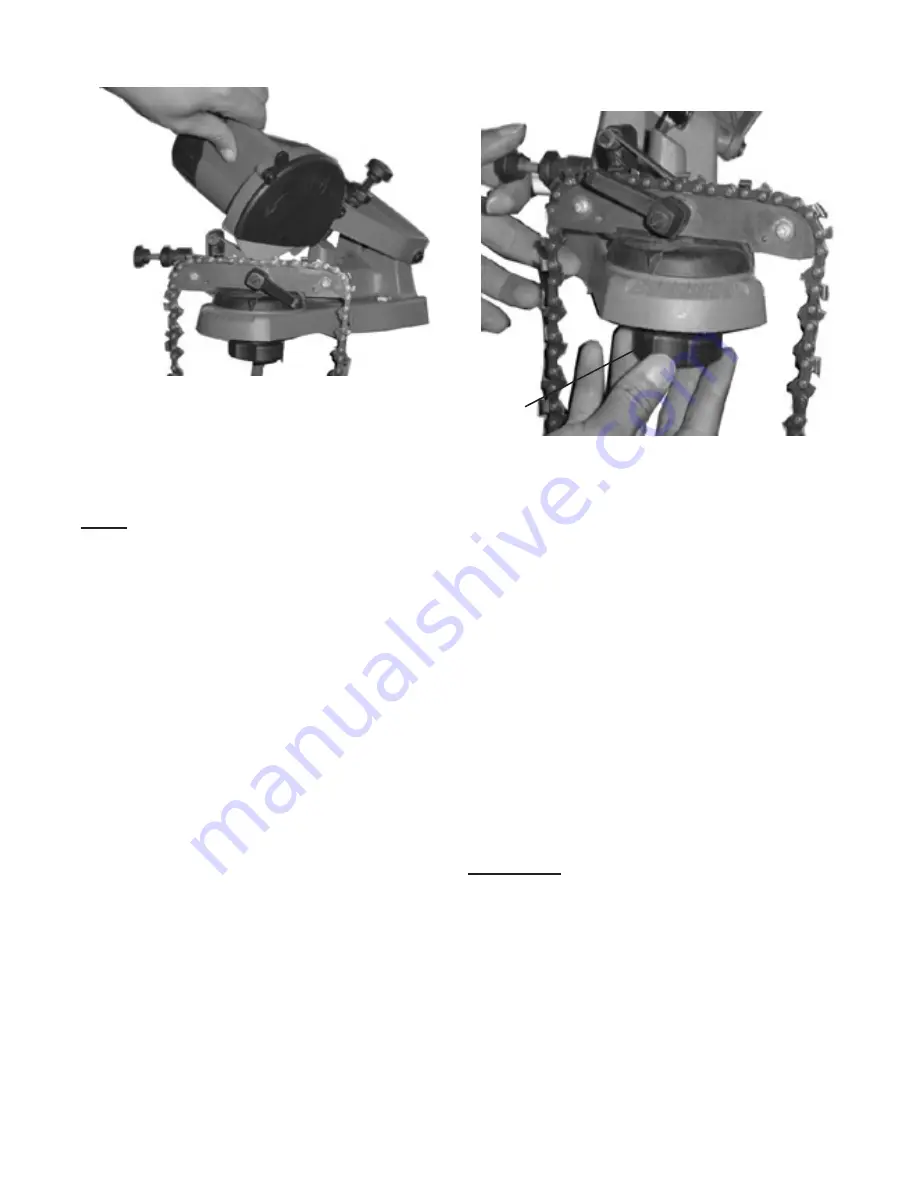

FIguRE 10

3. Slowly lower the grinding wheel as

shown in

FIguRE 10

. If you notice slight

errors in your settings, turn off the unit

and unplug it before you make your

adjustments.

Note:

A good grind occurs when the contact

between the wheel and the teeth are

gradual and smooth. Do not stop too

long on any tooth.

After sharpening one tooth, turn off the

4.

machine. Lift the Top Housing (4B),

release the Handle (34), and move the

chain so that the next link is positioned

in the Chain Stop (23). Tighten the

Handle (34).

Turn the machine back

on and continue

sharpening the next

tooth. Repeat this process until you have

sharpened all of the links set up for this

angle.

FIguRE 11

Lock

Wheel

(18)

5.

After you finished sharpening all of the

teeth set for your current angle, turn off

the machine by pushing the Switch (5B)

and unplugging the unit.

See FIguRE

11

Loosen the Lock Wheel (18) and reset

6.

the angle so that the first tooth that

hasn’t been sharpened is positioned

against the Chain Stop (23) and locked

in, as explained on page 6.

As you did with the first half of the chain,

7.

be sure to lower the Top Housing (4B)

so that the Grinding Wheel (8) skims

the chain tooth, and lock it in place. See

page 6. Follow all of the steps on page

6 double checking everything before you

plug in the machine and turn it on again.

WARNINg!

Remember to turn off the

machine and unplug it if you need to

make any adjustments.

After you repeat all of the steps under

8.

Sharpening on page 7, your chain is

ready to be mounted on your saw.