Page 11

For technical questions, please call 1-800-444-3353.

SKU 93213

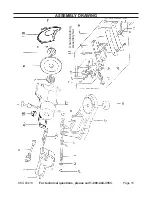

FIguRE 7

Lock Stop (6)

6. Hold it at that position while you tighten

the

Lock Stop (6)

so that the wheel will

only go down to that point. See

FIguRE

7

.

Depending on the amount of material

7.

you wish to remove, tighten or loosen the

Lower Knob (26) and set the Lock Nut.

See

FIguRE 5

. The Lower Knob (26)

has a Lock Nut which will determine how

much material is removed. Once you

set the Lock Nut, fully tighten the Lower

Knob (26).

FIguRE 8

Handle

(34)

Limiting

gauge

8. Lock the chain in the Sliding Guides (31)

by turning the Handle (34). See

FIguRE

8.

The Handle (34) should be situated so

that you can easily release and tighten it.

You will need to release it each time you

move to the next link, and tighten it to

sharpen each link.

FIguRE 9

9. If the chain has been repeatedly

sharpened, the chain depth limiting

gauges may need to be taken down with

a flat file (not included). See

FIguRES

8 & 9

. File down each gauge so that

they are at a lower level than the cutting

teeth.

Sharpening

Put on your protective gear and make

1.

sure the immediate area is clear of

bystanders.

Plug in the Power Cord (3) and push the

2.

Switch (5B) to turn on the machine.