11

9-6 Diaphragm Damage Sensor

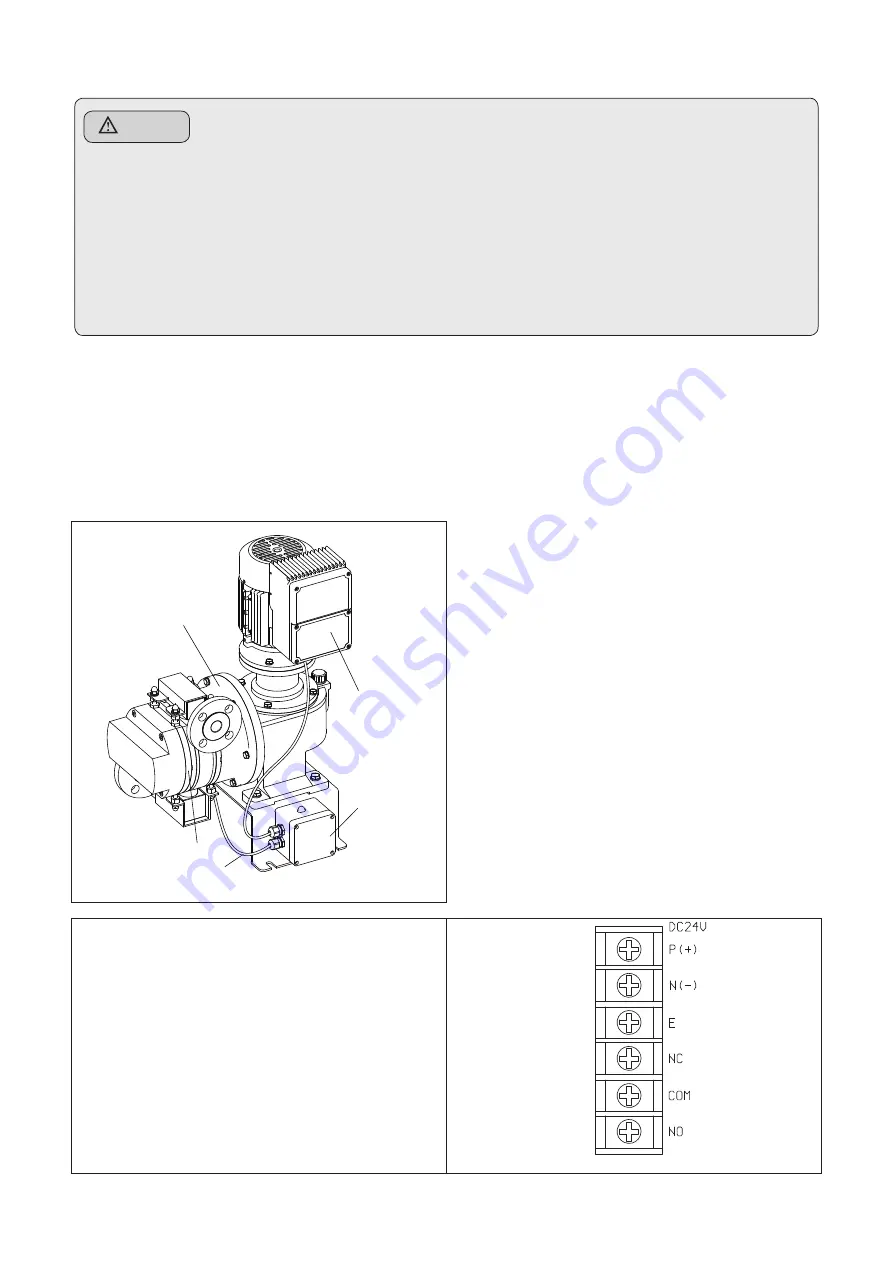

A detector sensing damage to the diaphragm is added to the PDS pump series, which is designed to

sense any damage to the diaphragm during pump operation and stop the pump to protect the pump

system. A sensor is mounted on the gear box flange and the front flange; when the diaphragm gets

damages, it senses fluid leaked at its back and sends a signal. This system is easy to install.

The BLDC M/C UNIT or a separate inverter receives the detection signal and brings the pump to a stop.

The diaphragm sensor and the BLDC driver

are wired at the factory before the product is

shipped.

The lamp gets lit when the sensor detects any

damage to the diaphragm. The operator can

monitor damage to the diaphragm using the

trip of the BLDC driver terminal block.

When an induction motor is used, the operator

can monitor the condition of the diaphragm

using the relay of the detector. Do wiring to the

terminal block of the detector in reference to

the following instruction.

Input Power : DC24V 300mA

Relay Spec. : SPDT 2A DC30V

Cable Standard : AWG18~26

Cable Connector Standard : PF 3/4″

P(+), N(-) : Input Power

E : Ground

NC, COM, NO : Relay

Caution

•

After checking the power specification of the BLDC M/C UNIT before wiring, connect the pump to the

rated power. If not, it may cause trouble and fire.

•

Pump should be properly grounded in order to prevent electric shock.

•

Entrust the wiring to electrical engineer.

•

Install regulated Magnet Switch and Thermal Relay for the adjustment and maintenance of the pump.

•

Use standardized parts in wiring and fully pay attention to safety in accordance with the technical

standard & wiring regulation of the electrical equipment.

•

Reverse rotation of the motor causes trouble, so wire the motor’s power so that the motor’s

rotation direction is clockwise.(This is only for Inverter and general motor.)

Front flange

Sensor Cable

Terminal

box

BLDC M/C

Unit

Gearbox

flange