BRTRO-420 Drawer Type Reflow Oven Operating Manual

- 8 -

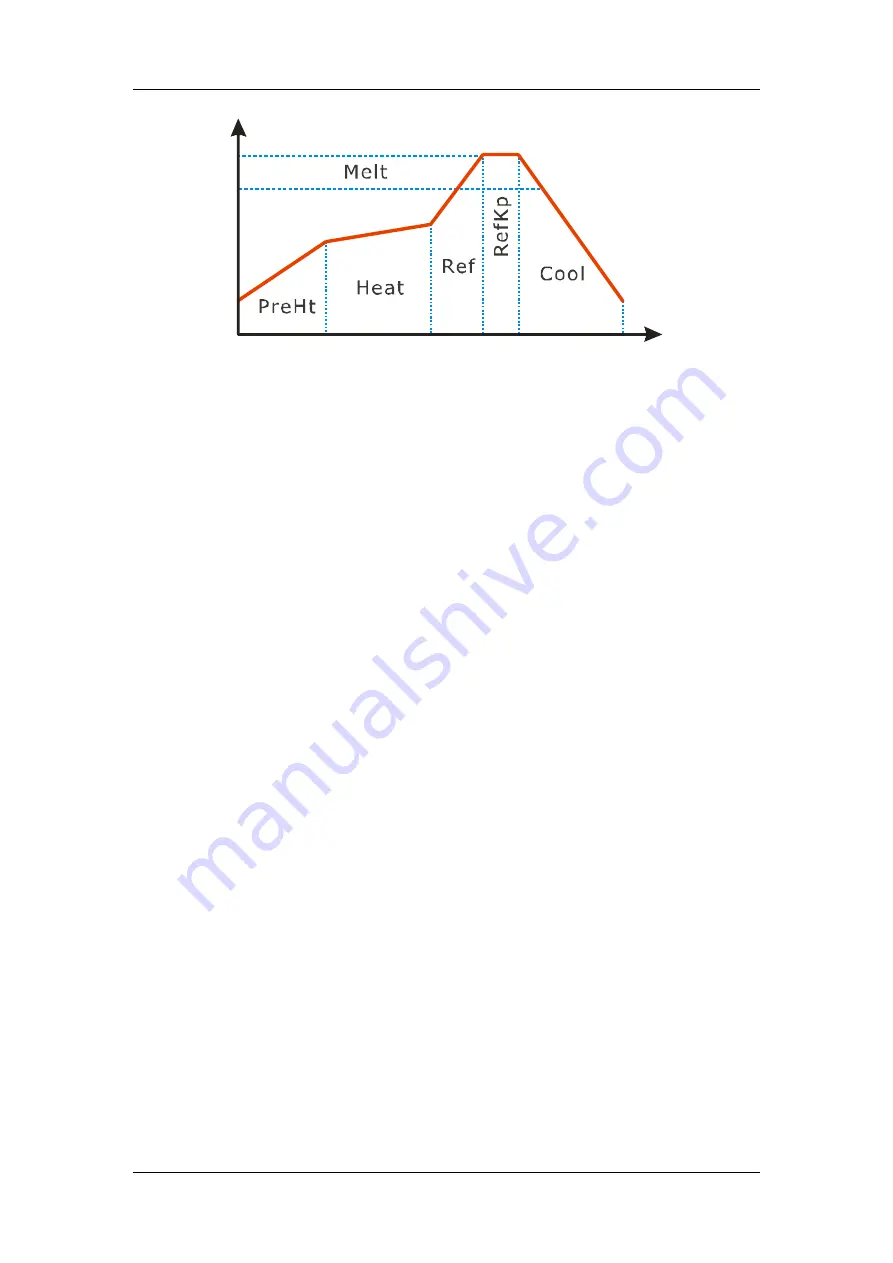

It is very important that a suitable reflowing curve is a guarantee of good

welding quality. However, Adjust reflowing curve will become very simple as long

as you have got the right method. The method is generally divided into the

following three steps.

Check the reference manual of solder paste, set the initial curve according to

the instructions in the manual;

Adjust the curve according to the maximum acceptable temperature of the

components, so as to prevent damage to the components in welding process

by high temperature;

Take actual welding test, and adjust curve according to the welding effect.

The function of each section and the points for attention of reflowing curve are

introduced below, in addition, a detailed description can be found in the manual of

solder paste.

PreHt

: Preheating section, used for rapid heating, heat the circuit board to

the temperature of solder paste to start work, the target temperature of this

section should not be set too high, and heating time not too long.

Temperature too high or time too long is the main reason of solder paste

collapse, tiny balls around the pads, solder sticking together;

Heat

: Heating section, this section mainly makes the temperature to the

same on circuit board, and the flux in solder paste begins to work at the

same time. The temperature rise rate of this section is smaller than the

previous, and the curve looks slower too, but if the temperature is too high