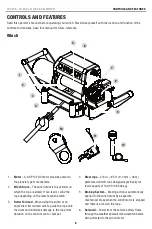

100776 - 10,000 LB. (4536 KG) WINCH

ASSEMBLY

8

ASSEMBLY

Your CPE 10,000 lb. (4,536 kg) winch is designed with

a bolt pattern that is standard in this class of winch.

Many winch mounting kits are available that utilize this

bolt pattern for the most popular trucks and Sport Utility

Vehicles. If you cannot find a kit locally, contact CPE and

we will provide you with the name of a dealer near you.

If you will utilize the CPE Speed Mount

TM

hitch adapter,

you must ensure that the three major sections (motor,

drum and gear housing) are properly aligned. Proper

alignment of the winch will allow even distribution of the

full-rated load.

!

CAUTION

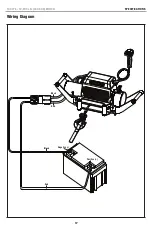

Mounting bolts must be SAE grade 5 or better and

torque to 34 ft. lb.

!

CAUTION

If utilizing a mounting plate, ensure that the three

major sections (motor, drum, and gear housing) are

properly aligned. Proper alignment of the winch will

allow for even distribution of the full rated load.

"

NOTICE

The type of vehicle to which the winch and mounting

channel will be applied, will dictate the type of

mounting kit that should be used (Speed Mount

TM

hitch adapter, standard mounting channel, or specialty

mounting kit).

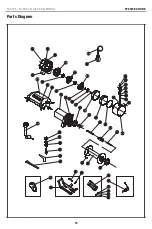

Mounting the Winch

1. Extend the arms of the Speed Mount™ hitch

adapter and secure with 4 M8 bolts and M8 nuts.

"

NOTICE

Please use either middle hole or outermost hole, as

the innermost hole interferes with this style roller

fairlead.

2. Insert 2 M10

×

35 bolts to the mounting channel

hole and attach the roller fairlead to the mounting

channel with the 2 flat washers, lock washers and

nut M10 provided.