9

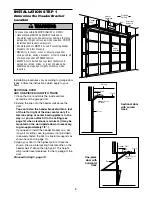

Header Wall

Vertical

Centerline

Vertical

Centerline

of Garage

Door

2x4

Unfinished

Ceiling

2x4

OPTIONAL

CEILING MOUNT

FOR

HEADER BRACKET

Structural

Supports

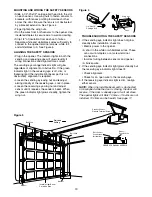

ONE-PIECE DOOR WITHOUT TRACK

1. Close the door and mark the inside vertical

centerline of your garage door. Extend the line

onto the header wall above door, as shown.

If headroom clearance is minimal, you can install

the header bracket on the ceiling. See page 10.

If you need to install the header bracket on a 2x4

(on wall or ceiling), use lag screws (not provided)

to securely fasten the 2x4 to structural supports

as shown.

2. Open your door to the highest point of travel as

shown. Measure the distance from the top of the

door to the floor. Subtract the actual height of the

door. Add 8" to the remainder. (See Example).

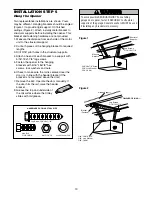

3. Close the door and draw an intersecting horizontal

line on the header wall at the determined height.

NOTE:

If the total number of inches exceeds the

height available in your garage, use the maximum

height possible, or refer to page 10 for ceiling

installation.

Door

Highest Point

of Travel

Header Wall

Pivot

Distance

Floor

One-piece door without track:

pivot hardware

Header Wall

Highest Point

of Travel

Door

Floor

Distance

Jamb

Hardware

One-piece door without track:

jamb hardware

EXAMPLE

Distance from top of door

(at highest point of travel) to floor ......................

92"

Actual height of door .......................................... -88"

Remainder..........................................................

4"

Add .....................................................................

+8"

Bracket height on header wall............................ =12"

(Measure UP from top of CLOSED door.)

Proceed to Step 2, page 10.