SKU 99637

For technical questions, please call 1-800-444-3353.

Page 7

PRODUCT SPECIFICATIONS

Air Pressure Range

70-90 PSI

Air Hose Requirement 3/8” I.D.

Air Inlet

1/4” -18 NPT

Air Consumption

6.0 CFM

Fastener Type

Staples with Plastic Caps

Staple Length

3/8” to 1-1/4”

Staple Crown Size

3/8” Crown

Staple Gauge

18 Gauge

Plastic Cap Diameter

1” O.D.

Plastic Cap Capacity

100 Plastic Caps

Magazine Capacity

Strip of 100 Staples

Firing Method

Intermittent Single Fire

Safety Trigger

Single Sequential Safety Trip

Mechanism

Adjustable Drive

Depth

Rotational Knob at Left Side of

Stapler

PRODUCT FEATURES

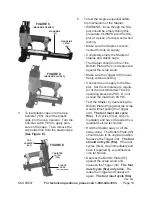

FIGURE A

DRIVE DEPTH

ADJUSTER

(47)

MAGAZINE

LATCH

(63)

TRIGGER

(39)

BOTTOM PLATE

(95)

CANISTER

LATCH

(104)

PLASTIC

CAP

CANISTER

(105)

EXHAUST

CAP

(1)

MAGAZINES

A & B

(67, 73)

TOOL SET UP/ASSEMBLY

Read the ENTIRE IMPORTANT

SAFETY INFORMATION

section at the beginning of this

manual including all text under

subheadings therein before set

up or use of this product.

Note:

For additional information regarding

the parts listed in the following pages,

refer to the Assembly Diagram near

the end of this manual.

Unpacking

When unpacking, check to make sure

that the item is intact and undamaged. If

any parts are missing or broken, please

call Harbor Freight Tools at the number

shown throughout the manual as soon as

possible.

• This air tool may be shipped with a

protective cap covering the Air Plug

(57). Remove this cap before set

up.

Air Supply

TO PREVENT

EXPLOSION:

Use only clean, dry, regulated,

compressed air to power this

tool. Do not use oxygen,

carbon dioxide, combustible

gases, or any other bottled

gas as a power source for this

tool.

REV 08k