SKU 99637

For technical questions, please call 1-800-444-3353.

Page 11

only once.

With the Trigger held,

carefully lift the Stapler and press it

against the scrap wood again.

The

tool must not cycle (fire).

If it fails

to perform in the manner explained

in bold, have it repaired by a quali-

fied service technician.

(See Figure F.)

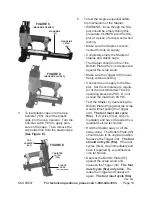

FIGURE A

TRIGGER

(39)

BOTTOM PLATE

(95)

Work Area Set Up

1. Designate a work area that is clean

and well-lit. The work area must not

allow access by children or pets to

prevent injury and distraction.

2. Route the air hose along a safe route

to reach the work area without creat-

ing a tripping hazard or exposing the

air hose to possible damage. The air

hose must be long enough to reach

the work area with enough extra

length to allow free movement while

working.

3. Secure loose workpieces using a vise

or clamps (not included) to prevent

movement while working.

4. There must not be hazardous ob-

jects (such as utility lines or foreign

objects) nearby that will present a

hazard while working.

General Operating Instructions

ALWAYS wear

ANSI-approved

safety impact goggles and heavy

duty work gloves when operating the

Stapler.

1. If an automatic oiler is not used, add

a few drops of Pneumatic Tool Oil

to the airline connection before use.

Add a few drops more after each

hour of continual use.

2. Check to make sure the single se-

quential safety trip mechanism of the

Stapler is working properly as previ-

ously discussed in this manual.

3. Load the Stapler with staples and

plastic caps as previously discussed

in this manual.

4. Connect the air supply to the Stapler,

and set the compressor’s regulator

between 70 and 90 PSI.

5. Rotate the Exhaust Cap (1) so that

the exhaust air blast will be directed

away from the operator.

6. Test for proper fastener penetration.

If necessary, adjust per paragraph 2

of tool Set-up Section on page 9.

7. To fire, place the Bottom Plate (95)

of the Stapler on the workpiece. The

Stapler should not cycle (fire) if the

Bottom Plate is not depressed. Once

REV 08k