Page 9

For technical questions, please call 1-800-444-3353.

SKU’s 40072,

40073, & 97521

3.

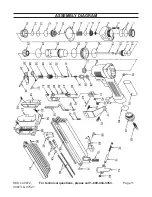

FIGURE 2

Safety (52)

Safety

Cover (54)

Lift the Safety Cover (54) off the top of

the stapler - see

Figure 2

.

4.

FIGURE 3

Driver

(19)

Driver

Cover

(57)

Carefully slide the Driver Cover (57) off

around the Safety (52) and remove the

jammed staple - see

Figure 3

. Use pliers

to remove a stuck staple.

5. Inspect the Driver (19) for bends

or breakage - see

Figure 3

. If it is

damaged, do not use the tool until it is

repaired by a qualified technician.

6. Lightly oil the Driver (19) and replace the

Driver Cover (57). Replace the Safety

Cover (54), being careful to line up the

bolt holes and fit the Safety (52) into the

slot. Replace and securely tighten all of

the Safety Cover Bolts (53). The Safety

(52) must move without sticking.

7. Reload the Stapler.

8. Reconnect the Stapler to the air hose.

9. Press the Safety (52) of the Stapler

against an appropriate piece of scrap

wood and test fire the Stapler several

times, checking for proper operation.

10. Disconnect the Stapler, remove the

staples, and store the Stapler in a

location out of children’s reach.

MAINTENANCE

TO PREVENT

SERIOUS INJURY

FROM ACCIDENTAL OPERATION,

BEFORE ANY MAINTENANCE OR

REPAIRS ARE DONE (including

clearing jams):

• Wear ANSI-approved safety

goggles with side shields.

Other

people in the work area must also

wear ANSI-approved impact safety

goggles with side shields.

• Release the trigger.

• Detach the air supply.

• Attempt to fire the Tool into a

piece of scrap wood to ensure

that it is disconnected and is

incapable of firing any fasteners.

• Empty the magazine and leave it

open during service.

Note:

If the Stapler leaks air, continually

skips staples, does not drive the staple

properly, or the Trigger (39) or Safety

(52) do not move freely have it serviced

by a qualified service technician.

1. After each use, check the tightness on all

visible screws.

2. Wipe the Stapler clean daily with a

damp cloth and non-flammable cleaning

solution. Never soak the Stapler.

3. Make sure that no dirt or debris blocks

the fastener discharge area.

4.

Any maintenance, service, or

repairs, apart from those procedures

explained in this manual, are to

be attempted only by a qualified

technician.

REV 10a