Page 8

For technical questions, please call 1-800-444-3353.

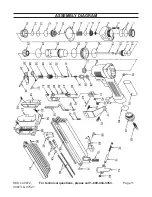

SKU’s 40072,

40073, & 97521

With the Trigger held, carefully lift the

nailer and press it against the workpiece

again.

The tool must not cycle (fire)

.

If it fails to act in the manner explained

in bold, have it repaired by a qualified

service technician.

Loading Staples

ALWAYS WEAR ANSI APPROVED

IMPACT SAFETY GOGGLES

WHEN RELOADING OR DOING

ANY OTHER MAINTENANCE ON

THIS TOOL.

Other people in the

work area must also wear ANSI

approved impact safety goggles.

Warning! Make sure the Stapler is not attached

to the air hose whenever loading the tool.

1. Release the Latch (69) and pull back on

Magazine B (61).

2. Insert a row of clean, undamaged

staples with the crowns up.

3. Push Magazine B (61) forward until the

Latch (69) snaps into place.

Operating the Stapler

1. Attach the Stapler to the air supply at the

Air Plug (82). Start your compressor and

check the pressure, making sure it is set

at the recommended 60-100 PSI and not

to go over the maximum 100 PSI.

2. To fire, place the nose of the Stapler on

the workpiece. The Stapler should not

fire if the nose is not depressed. Once

depressed, gently and briefly squeeze

the Trigger (39) once.

Do not fire

repeatedly.

Staples could bounce off

of one another, damaging the work

piece or causing PERSONAL INJURY.

3. After disconnecting the Stapler, the Nut

(39), near the trigger, can be turned to

adjust the depth. After adjusting, be sure

to practice on scrap wood before working

on a project.

Clearing Jams

TO PREVENT

SERIOUS INJURY

FROM ACCIDENTAL OPERATION,

BEFORE ANY MAINTENANCE OR

REPAIRS ARE DONE (including

clearing jams):

• Wear ANSI-approved safety

goggles with side shields.

Other

people in the work area must also

wear ANSI-approved impact safety

goggles with side shields.

• Release the trigger.

• Detach the air supply.

• Attempt to fire the Tool into a

piece of scrap wood to ensure

that it is disconnected and is

incapable of firing any fasteners.

• Empty the magazine and leave it

open during service.

1. Disconnect tool from air hose, empty

Magazine A (66) of staples, release

any built-up air pressure, and leave the

magazine open, as explained above.

2.

Safety Cover

Bolt (53)

FIGURE 1

While doing this step and the next, hold

the Stapler pointed away from you and

any other people or fragile objects - see

Figure 1

. Remove all three Safety Cover

Bolts (53) on the Safety Cover (54).