SKU 93496

For technical questions please call 1-800-444-3353

Page 5

Warning: The warnings, cautions, and instructions discussed in this instruc-

tion manual cannot cover all possible conditions and situations that may oc-

cur. It must be understood by the operator that common sense and caution

are factors which cannot be built into this product, but must be supplied by

the operator.

Air Pressure Supply

This tool is designed to operate with a maximum air pressure of 125 psi. You must

use an air regulator, set at 125 psi or below.

Note:

Performance of this tool may

vary depending on variations in local air pressure.

In use, this tool will use 2 - 4 Cubic Feet per Minute of compressed air at 125 psi.

For satisfactory performance, you must use an air compressor capable of deliver-

ing this volume of air at the stated pressure.

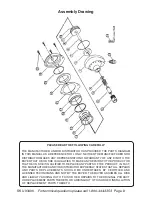

We recommend that you use both a filter and an in-line oiler in your air supply

system as illustrated in the diagram below. These components are not included

with this tool, but are available from Harbor Freight Tools.

If you do not use a filter and in-line oiler, put a few drops of water displacement oil

into the air line before each use. After each use, the Air Hand Nailer should be

carefully drained of collected moisture and sprayed with a water displacement oil.

We recommend that you install a quick-release nipple (not included) into the Air

Inlet (23). Quick release connectors at all points in an air pressure system make

your work easier.

Air Palm

Nailer

Unpacking

When unpacking, check to make sure the following parts are included.

Air Palm Nailer Tool

Leather Cover

(1) 4mm Hex Key

If any parts are missing or broken, please call Harbor Freight Tools at the number

on the cover of this manual.

REV 11/06