Page 18

For technical questions, please call 1-800-444-3353.

SKU 67708

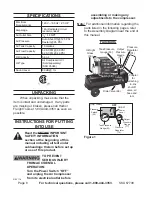

PartS lISt

Part

description

Qty

1

Cover

1

2

Elbow

1

3

Start Valve

1

4

Spring Washer M6

8

5

Screw M6 x 50

4

6

Air Filter

1

7

Cylinder Head

1

8

Head Gasket

1

9

Valve Plate

2

10

Metal Gasket

1

11

Valve

2

12

Valve Plate Gasket

1

13

Cylinder

1

14

Bolt M8 x 30

2

15

Spring Washer M8

3

16

Cylinder Gasket

1

17

Pin

1

18

Compression Ring

2

19

Oil Ring

1

20

Wrist Pin Retainer

2

21

Piston

1

22

Connecting Rod

1

23

Screw M6 x 20

5

24

Hex Nut M6

3

25

Crank Shaft

1

26

O-Ring

2

26a Zip Tie

1

27

Capacitor

1

28

Screw M8 x 20

1

29

Capacitor Bracket

1

30

Hex Nut M8

1

31

Crank Case Cover

1

32

O-Ring

1

33

Oil Sight Glass

1

34

O-Ring

1

35

Drain Plug M5 x 10

1

36

O-Ring

1

37

Oil Breather Plug

1

38

Crankcase Cover Gasket

1

39

Pump Crankcase

1

40

Washer M5

10

41

Screw M5 x 16

10

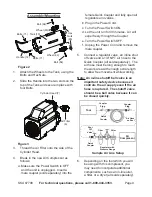

Part

description

Qty

42

Manual Overload Protector

1

43

Oil Seal

1

44

Bearing

1

45

Rotator

1

46

Bearing

1

47

Stator

1

48

Automatic Thermal Protector

1

49

End Cover

1

50

Fan

1

51

Circlip

1

51a Plain Washer 5

4

51b Spring Washer 5

4

51c Bolt

4

52

Connector

1

53

Tank Pressure Gauge

1

54

Pressure Switch

1

55

Unloader Tube

1

56

Nut

1

57

Ferrule

1

58

Check Valve

1

59

Ferrule

2

60

Nut

2

61

Exhaust Tube

1

62

Cooling Fin

1

63

Wheel

2

64

Bolt M12 x 55 (washer/bushing

assembly)

2

65

Hex Nut M12

2

66

Drain Valve

1

67

Foot Pad

2

68

Washer

2

69

Screw M6 x 25

2

70

Tank

1

71

Bolt M6 x 10

4

72

Handle

1

73

Safety Valve

1

74

Pressure Regulator

1

75

Motor Cord

1

76

Quick Coupler

1

77

Output Pressure Gauge

1

78

Plug

1